Dear Santa,

How are…. Let me jump right to the point: Christmas music is like microplastics – everywhere, irritating and harmful to living organisms. In right amounts I enjoy Christmas music during December, but not in the autumn. Strangely malls, various shops and service bureaus play it, get this, starting from October. I give them business, and they want… to repel me?

Well they managed just that. Thank you Santa, for giving me all the convenient webshops, postal and grocery delivery services that streamline my everyday life. The music nuisance is pretty much gone now. Outstanding – but do you already have a plan laid out for microplastics?

2018 Was Awesome

End of 2017 I was nervous about the talent pool in our business. Turns out I just wasn’t completely in the loop. To name a few examples, Pavel had rotated himself to Impinj and Goetz and Jason were re-discovered at StoraEnso. Markus the mountain runner stepped over to the end user side in mid-2018. Harri retired, which is a loss but superb news for his granddaughter. Santa, any way to circulate Sipi back to RAIN business?

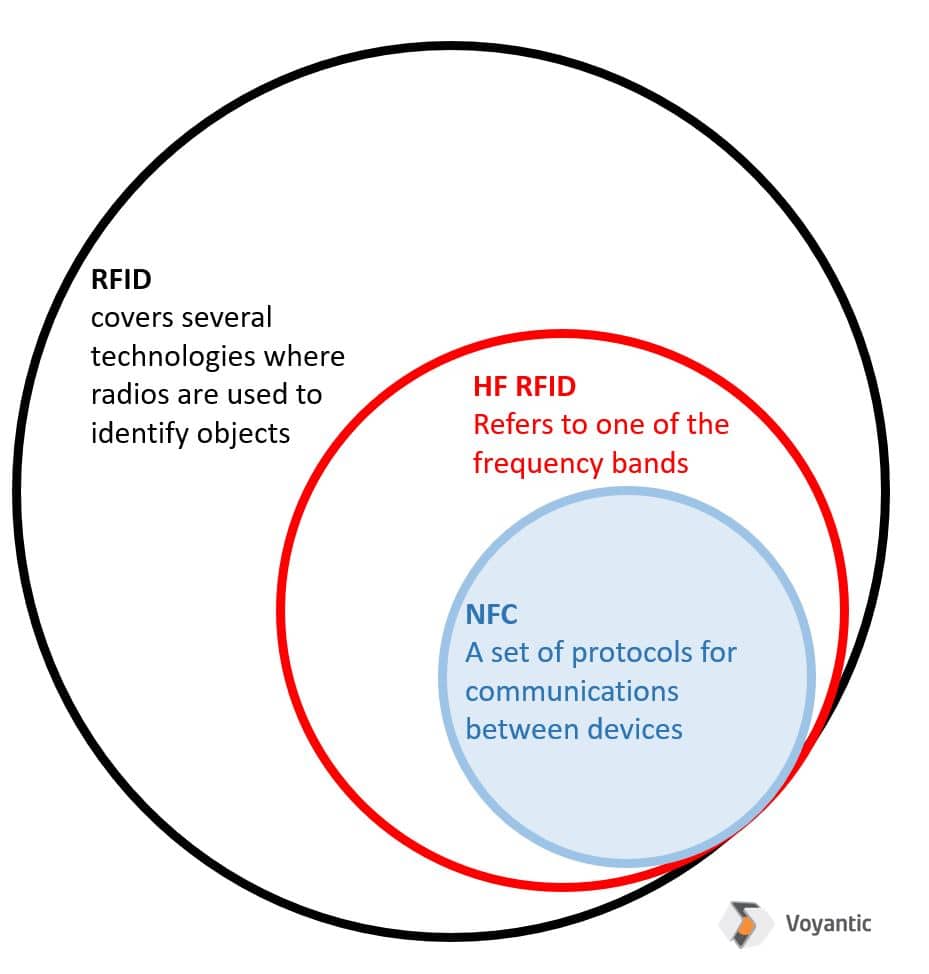

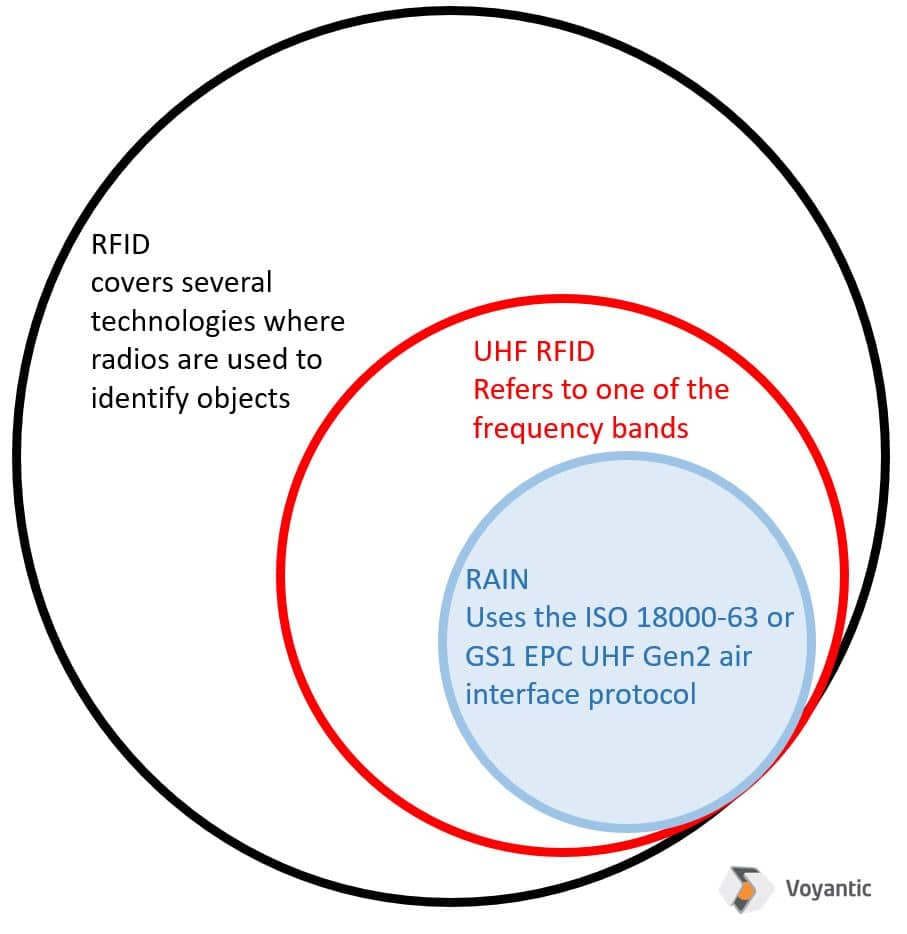

Both the RAIN name and RAIN market enjoyed a well deserved boost. The RAIN Alliance grew to over 160 members and according to Hervé D’Halluins’ presentation in Xiamen, Decathlon has achieved 100% RAIN tagging coverage on it’s merchandise!

Best of all there seems to be a consensus among manufacturers, brands and retailers that source tagging is the way to go – a message also amplified by the Project Zipper results. I couldn’t have asked for more, and am grateful to you, dear Santa.

2019 to Embrace Mistakes

Santa, as we both know from the frosty Finnish lakeside, without mistakes there is very little learning.

Take the Brexit as an example. Let it be hard or soft, but it’s going to hurt the British people like an ice hockey puck hitting the chin, especially those on the low-income end. As the tide across the English Channel is right, let’s all admit that Brexit was just an epic mistake and welcome the Great Britain warmly back to the union. A few hugs and pints will brush off the ashes, and no-one will go down that path ever again.

I don’t dare to wish anything specific regarding Brexit as such, instead I hope we all would learn to embrace mistakes and failures – also the gigantic ones.

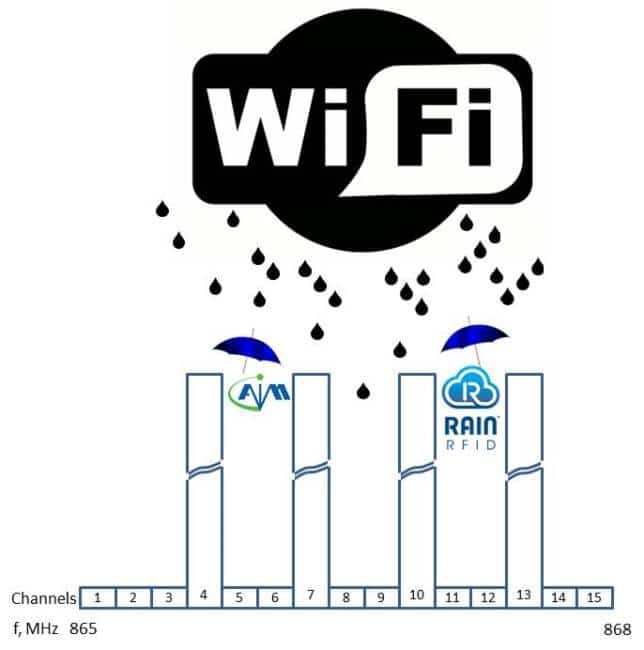

2019 to Schedule the Upper ETSI Frequency Band

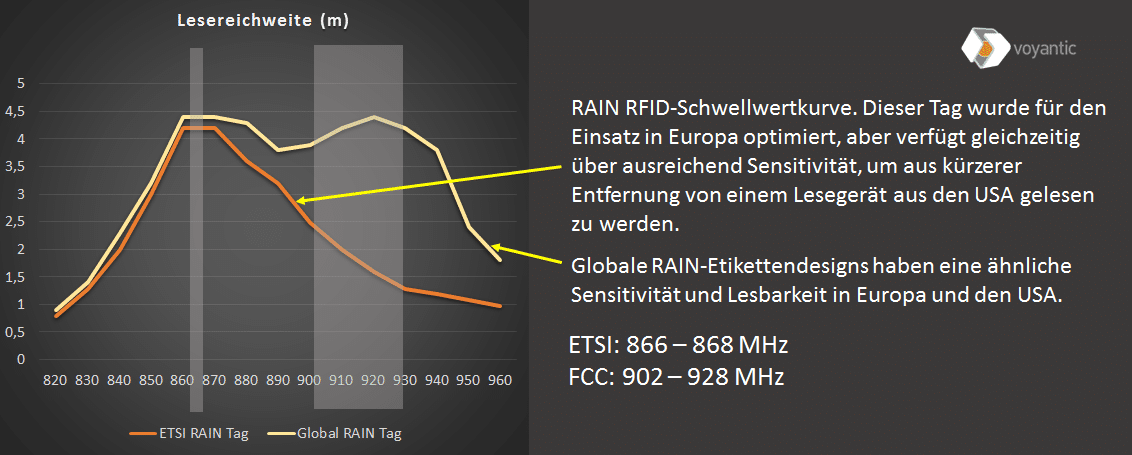

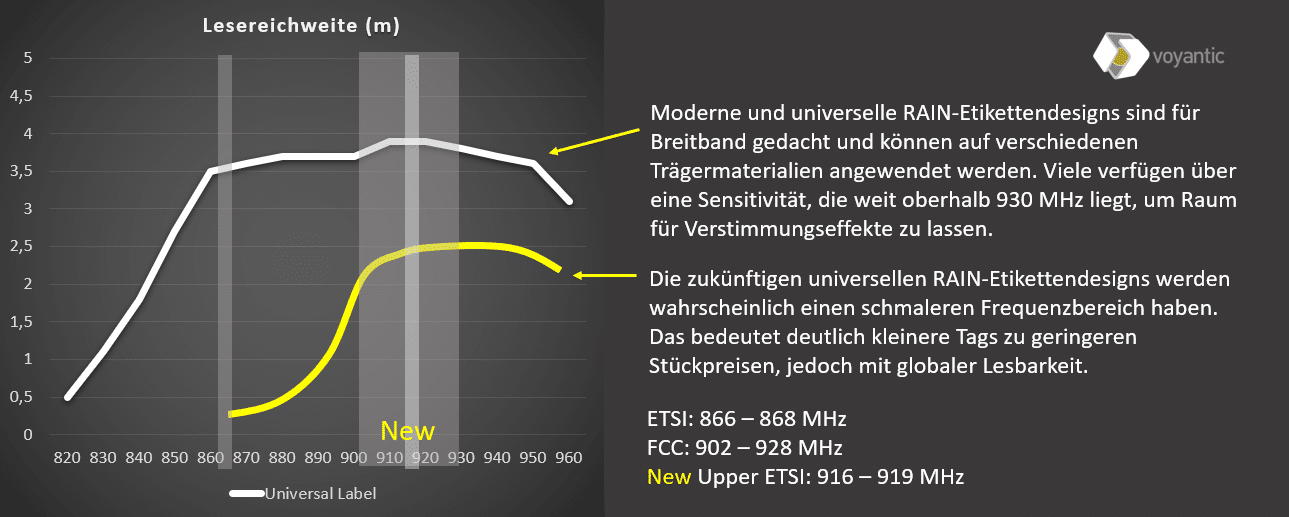

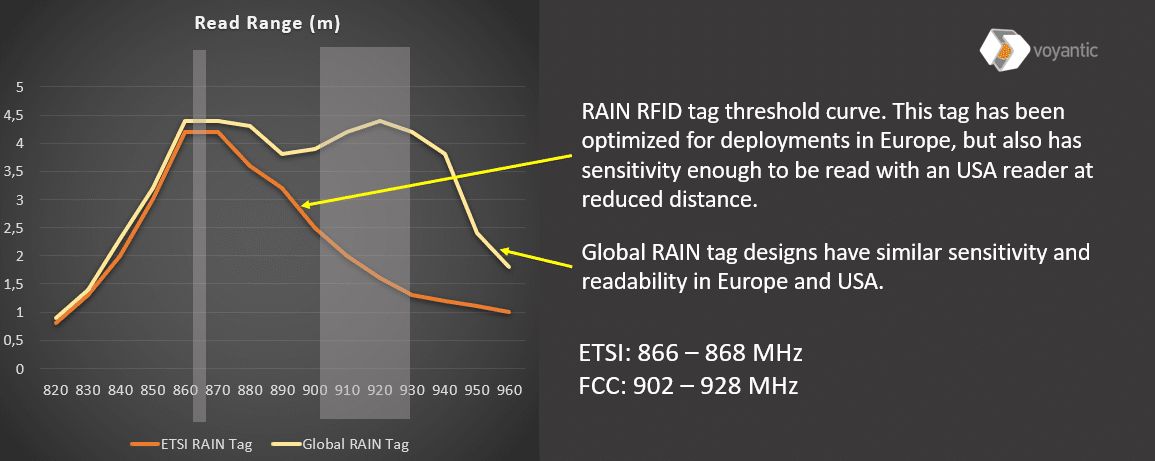

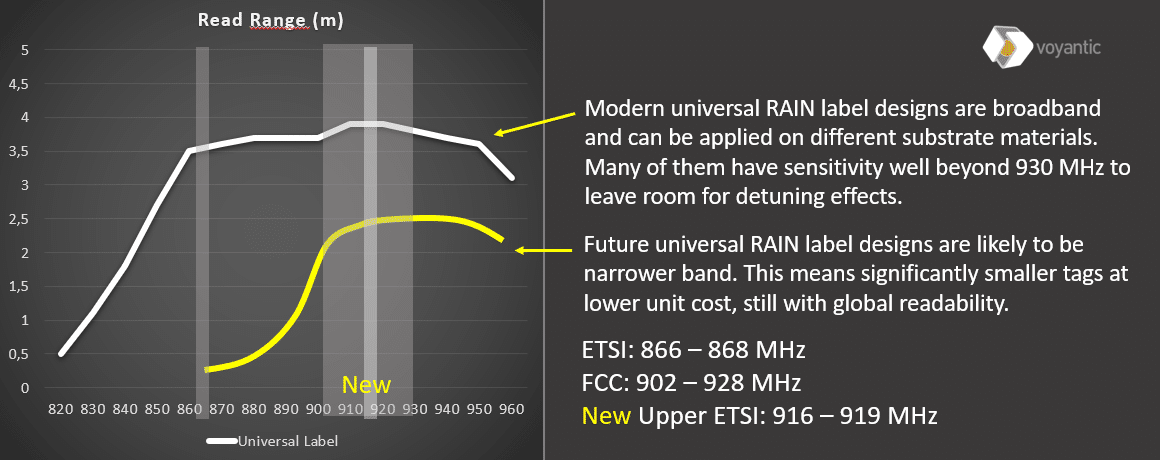

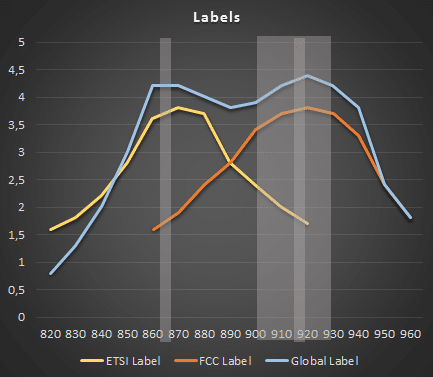

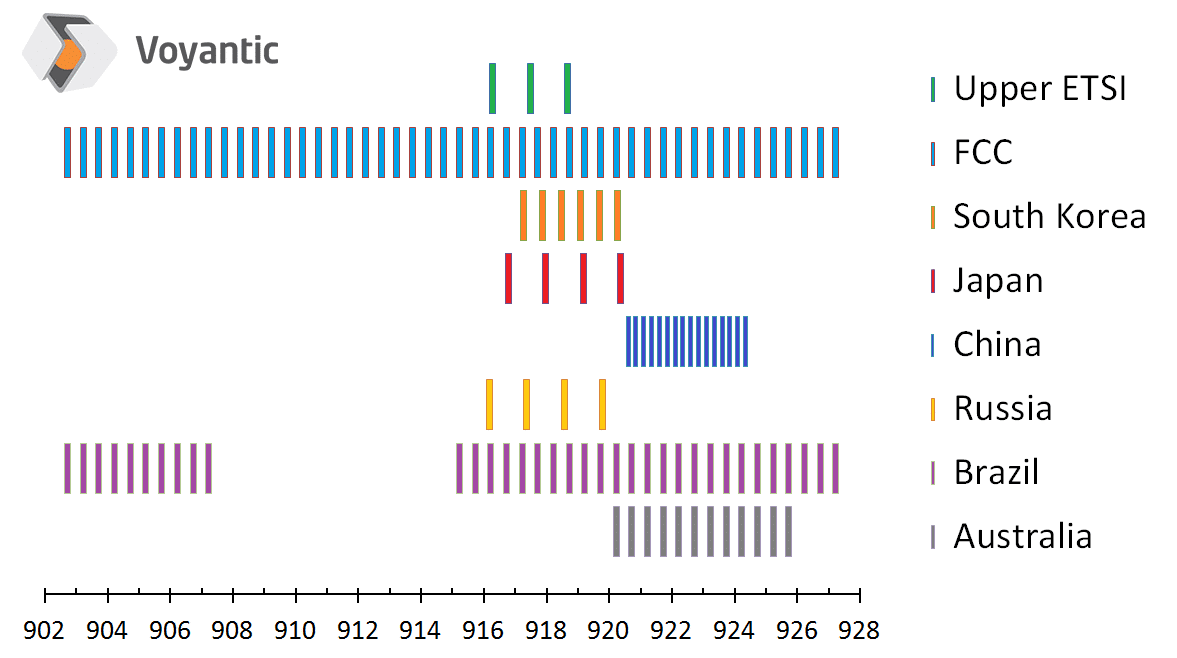

Santa, thanks for delivering the Comission Decision last October outside of my wishlist! The global harmonized RAIN Frequency band is already in the books, but not in practice. Understanding the complexities involved, it would be valuable to acquire an adoption plan across the European member states. We especially need the date when frequencies between 916-919 MHz become available for RAIN deployments in Germany.

2019 Let There Be Flooding

As annual tag delivery volumes go north of 20 Billion, we cannot expect applications to remain isolated from each other, as they nowadays still largely are. RAIN tag flooding basically occurs when RAIN applications start to overlap.

Take a sports event for example: the participants are wearing clothes and shoes purchased from Decathlon, making those items RAIN enabled. Together with their RAIN enabled race bib they next run over the race timing system antenna mat. That introduces serious tag flooding to the race timing system. Would this overlapping of applications be a problem? Assuming the correct numbering [ISO/IEC 20248] is used on all the tags AND the readers are properly configured, there should be no problem.

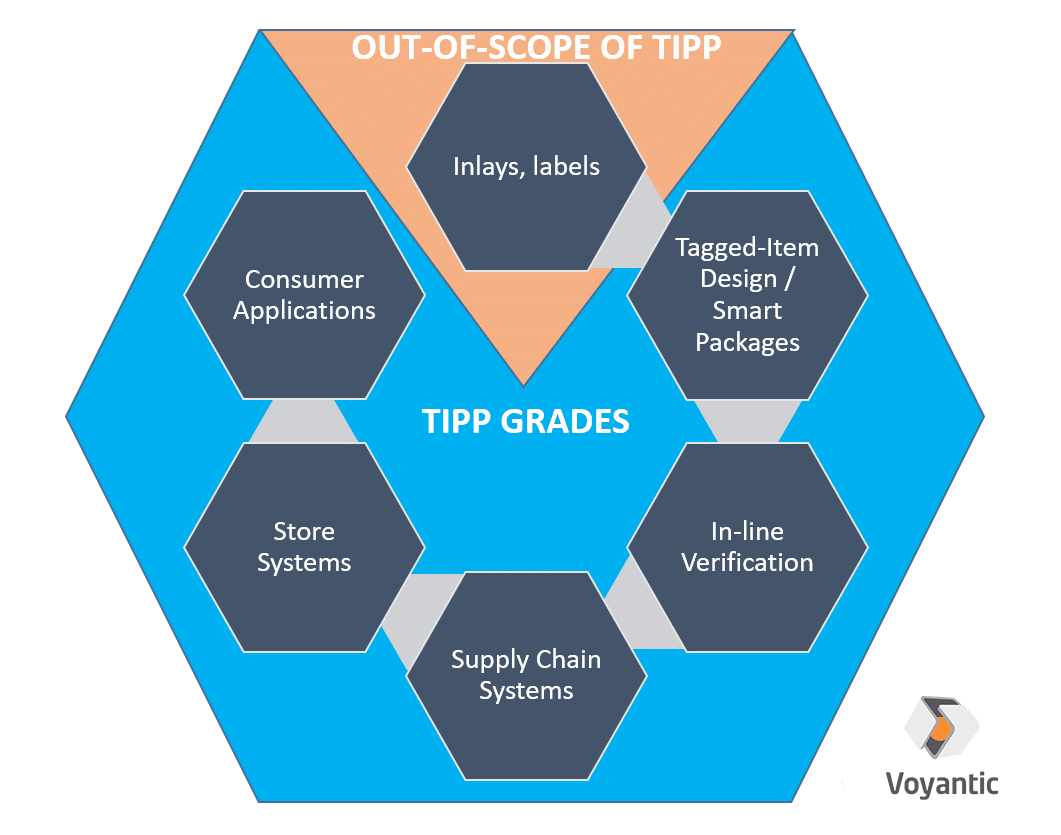

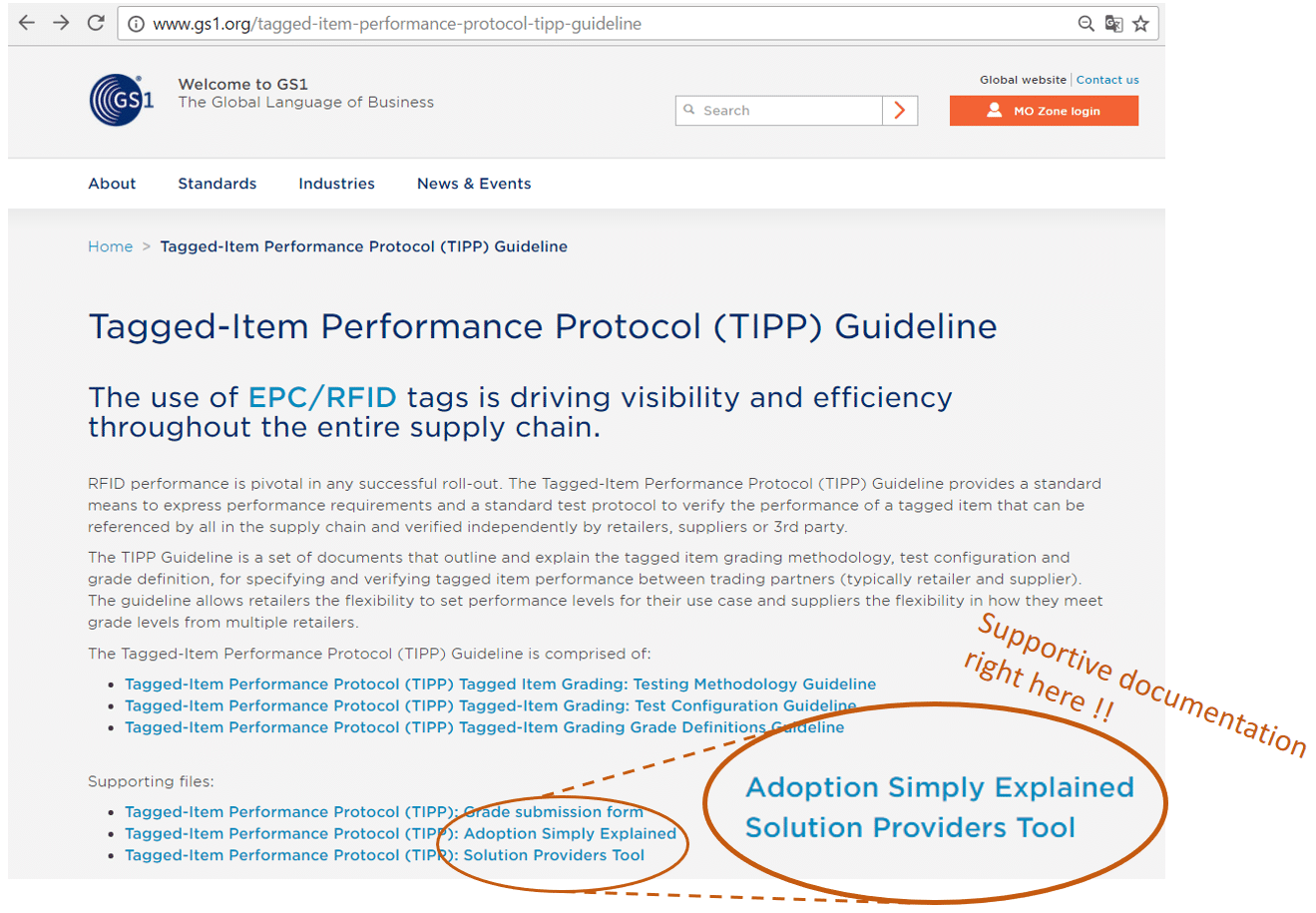

Flooding is good and it’s inevitable, because the market is growing. Dear Santa, we really need to start educating the RAIN solution providers to prepare for flooding. Luckily, Bertus Pretorius already started.

Getting Warmer

The future outlook for us winter dudes is not so bright. Santa, get wheels for your sleigh. No kidding matter. See you in a few days, ok? Travel safe.