Combine identification, sensors, low cost and years of life time together and you certainly end up with a disruptive mixture that is set to boil over in the near future. RAIN RFID sensors may not be a huge market just yet, but we can see many companies putting a lot of development effort on them. Read on to see an introduction to the six topologies that I’ve seen utilized so far.

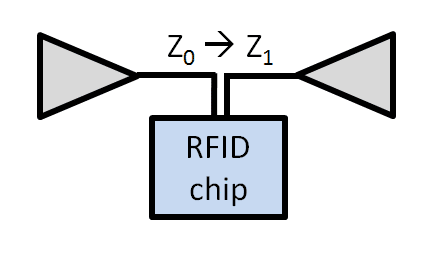

1) Affecting Antenna to Chip Matching

Right from the beginning of the UHF RFID, engineers have been aware of the inlay antenna’s sensitive nature to change its parameters whenever just about anything changes in its proximity. So, it didn’t take long for scientists to call it a sensor. No added energy was wasted on sensing electronics, therefore potentially long sensing ranges were expected. In practice, however, these type of sensors never got too much of a foothold on the market, as the tags were still sensitive to many measurable parameters, and not just one.

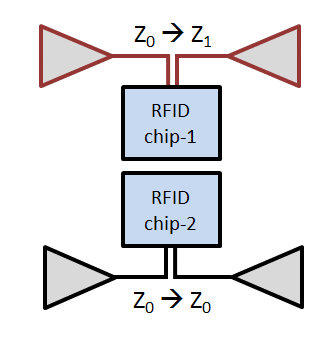

2) The Dual Tag Relative Approach

To address the real world problems of the previous approach, a simple improvement was soon used. This time, two similar inlays were encapsulated into one physical tag casing, but one of the antennas is made more sensitive to one particular property. For example, if salt impregnated foam is placed over one of the inlay antennas, it doesn’t affect the antenna when dry. However, when humidity rises, it will deteriorate the performance of this antenna at a much faster rate. The reader would poll both of these tags, typically of a sequential EPC code, and monitor the difference between the two RSSI levels.

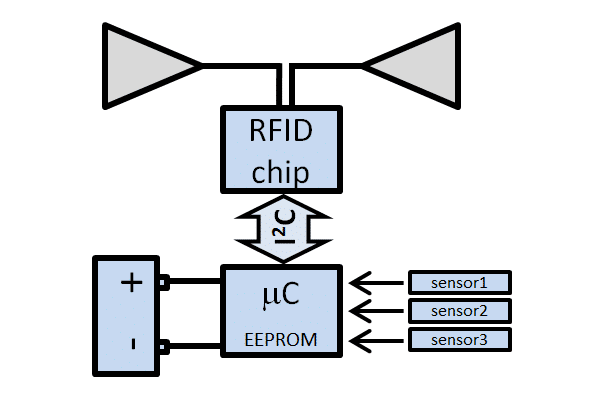

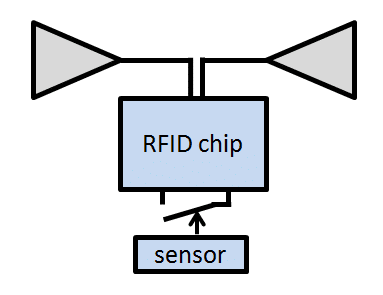

3) The Embedded Tag

A few years ago the most common type of sensor tag was the embedded type of tag. In this form one or several sensors and inputs can be monitored, logged into memory and read from there when needed. Practically any type of sensoring can be performed in this way, but the solution requires a battery. Although the battery does not sound like a too bad thing to have inside, however the advantage to other technologies, like Bluetooth LE, is rapidly lost. There are also several RFID chips that work with the same principle, but alone without a separate microcontroller.

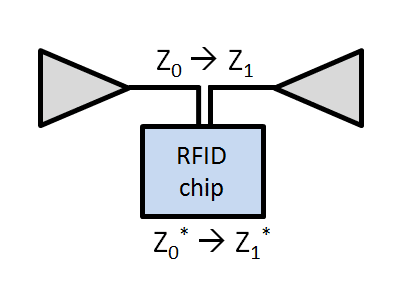

4) Using Automatic Chip Impedance Tuning

Adaptive chip impedance tuning was long awaited, and finally RF Micron was among the first to arrive to the market with a chip with that capability built-in. It didn’t take long till it was used to detect changes in the antennas proximity just like in the case 1. The biggest difference is that now the sensing result can simply be read from the tag memory and not from the RF properties of the tag.

5) Binary Sensing

Several ICs have a special pin called the tamper detection pin. Whether this pin is in contact with ground or not can be polled by the reader. It is thus not so difficult to turn this tamper function into a sensor with a bimetallic strip, mercury switch, level float, magnetic switch, NTC resistor, etc. The fact remains that this topology of sensor remains binary.

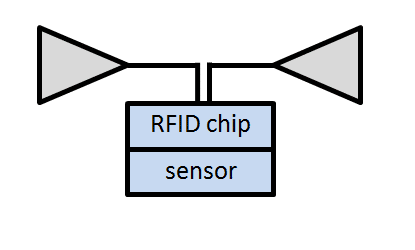

6) Inbuilt Sensing Capability

To bring potential cost down and optimize the energy consumption of the tag, the sensor is best integrated into the RFID IC itself. As no busses, microcontrollers, sensors, etc. need to be powered externally, the reading range can be potentially close to that of industry standard tags. The range of measured properties are more limited with this approach, temperature being the simplest candidate.

All this is to say that RFID sensoring can, in fact, be really simple. However, to get the solution working right also on-site with a known level of sensing accuracy requires advanced methods and a correct set of tools.

Getting It Right With Proper Tools

A number of RFID sensor developers are already using diverse functionalities in the Voyantic Tagformance systemto accelerate tag development cycles, optimize designs and to characterize their products. The more data there is in the sensor tag datasheet, the easier it is for anyone to take it into use!

If there is a particular type of testing you need to get done, but cannot find that particular function in our software GUI, please do not hesitate to contact us! Check out also our earlier blog post of passive RFID sensing!

Learn How to Design Passive Sensor Tags

Download our application note “Utilizing Voyantic Tagformance to Speed Up Development of UHF RAIN RFID Sensor Tags” to learn how to design passive sensor tags!