Testing Solutions for Production

We help…

Inlay providers to ensure production quality corresponds to the designed quality. Our high-speed inline testing system gives full visibility into the performance of each tag, not just checking if they are functional.

Tag and label converters to ensure every delivered tag and label meets the quality requirements while giving visibility into the entire production process, enabling you to catch any issues early on. Following industry best practices for quality testing ensures your products pass certification requirements.

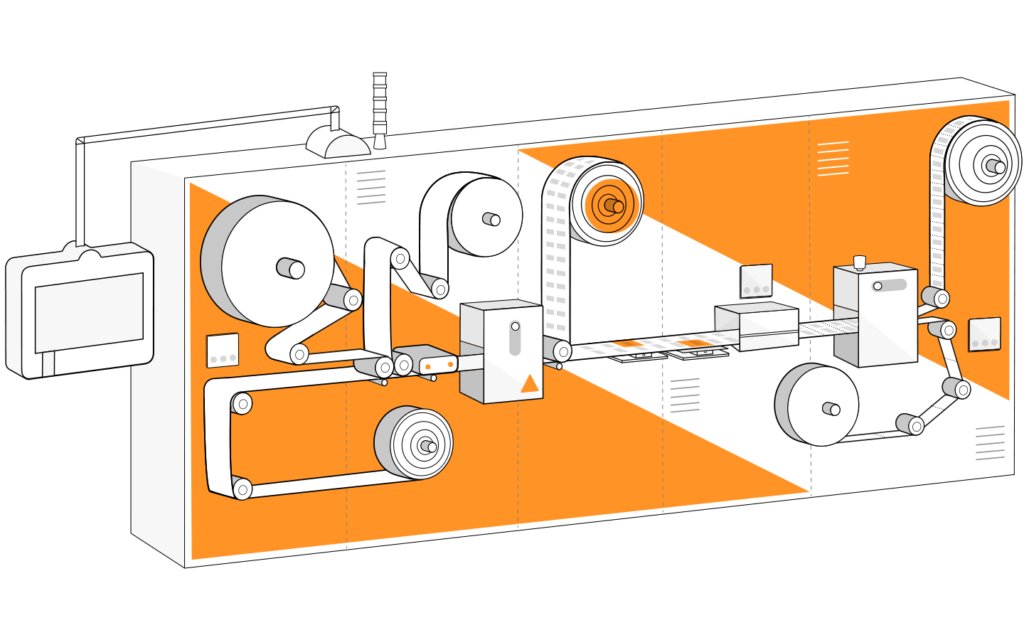

RFID and label converting machine manufacturers provide complete solutions for their customers, with a quality control system that is easy to integrate, modular, and scalable to fit practically any machine. We have decades of experience in RFID and can help you build your RFID expertise. Learn how we work with machine manufacturers here ›

Reliable and Accurate Testing Improves Efficiency

Our solutions include quality measurement systems for UHF and HF RFID tag manufacturing, as well as incoming inspection for end users.

The systems function efficiently in high speed production, and verify tags’ performance on several frequencies on a wide frequency range, not only if the tag is functional or not. Full performance visibility allows optimizing machine settings and processes for improved quality and yield.

Tagsurance 3 – Complete Quality Testing Solution for High-speed Production Lines

Tagsurance 3 is our next-generation inline testing and quality control system that is easy to integrate into production machines.

3 Free Resources for RAIN RFID Label Converters

Click through to 3 educational resources to help you get started with RFID label converting.

Systems for Production

Tagsurance® 3

Legacy Systems

Tagsurance® UHF

Tagsurance HF

RAIN RFID and NFC Production Process

Quality assurance in RAIN RFID and NFC tag manufacturing process is crucial. This page describes all stages of the process and offers an overview of the quality testing and encoding tools that can be used in IC attachment and any process step after that. Wherever you are on your RFID tag production journey, understanding the key concepts will help you to evaluate solutions and make better decisions.