Quality assurance in RAIN RFID and NFC tag manufacturing process is crucial. This page describes all stages of the process and offers an overview of the quality testing and encoding tools that can be used in IC attachment and any process step after that. Wherever you are on your RFID tag production journey, understanding the key concepts will help you to evaluate solutions and make better decisions.

1. Smart tag manufacturing process

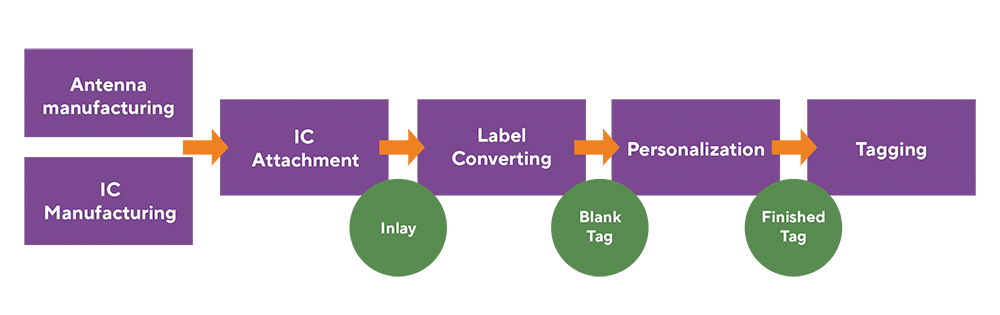

Antennas and ICs, or chips, are manufactured separately in their own processes. When the IC is attached to the antenna, the outcome is called an inlay. Inlays are then converted into different end products (tags) like labels, smart cards, hangtags, wristbands, etc. Inlays can also be embedded into other products as such or after being converted to a suitable format. The next step in the process is to add data to the tag. This printing, encoding, or programming is usually called personalization. It refers to not only programming the IC, but also adding logos, texts, and any visual, machine, or human-readable information to the tag. When the tag is ready, it is attached to an item in a tagging process.

1.1 Antenna manufacturing

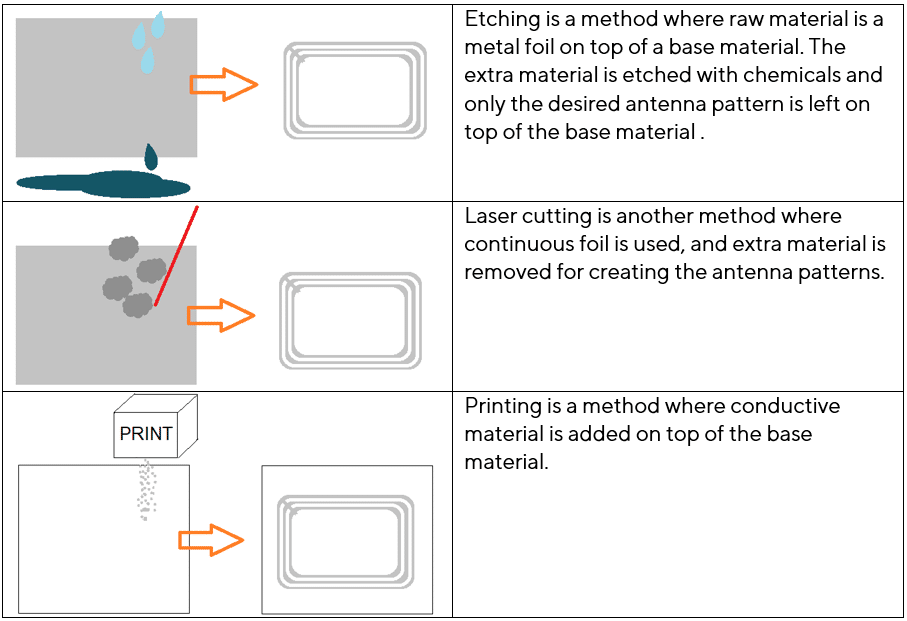

RAIN RFID and NFC tag antennas are manufactured from different conductive materials. The most common material is currently aluminum. Also, copper, graphene, and conductive inks are used.

Some manufacturers use other methods for creating conductive antenna patterns on top of the non-conductive base material, such as depositing vaporized metals.

1.2 IC manufacturing

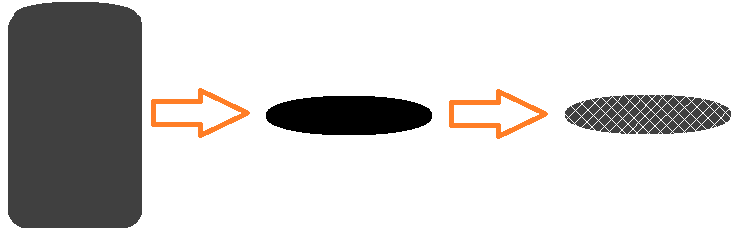

ICs, or chips, are mostly manufactured from silicon.

- First, a silicon ingot (large single crystal) is grown

- The ingot is then cut into thin slices aka wafers

- The required circuitry is then etched and deposited on the wafer

- Final step is to cut individual ICs on the wafer

Printed IC is a new production method, that has been taken recently into use.

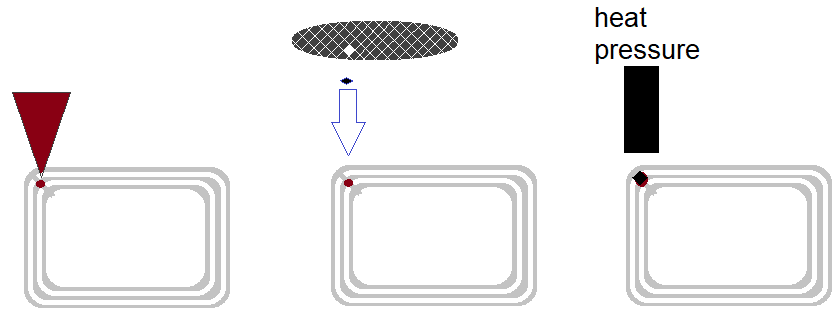

1.3 IC attachment

IC attachment is a process where the IC is connected to the antenna. The process is known also as chip attachment or chip bonding. First, a drop of conductive epoxy – anisotropic glue – is placed to the spot where the IC will be attached. Next, the IC is taken from the wafer and placed in the correct position. Then, the glue is cured with temperature and pressure. The curing hardens the glue and makes it conductive.

The outcome of the IC attach process is an inlay.

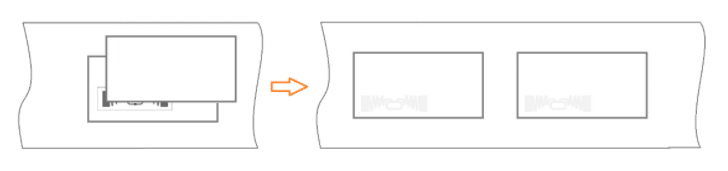

1.4 Converting

Converting is a process where the inlay is transformed into a physically finalized tag.

Label converting: When an inlay is converted to a label, a layer of protective material and possibly a separate layer of printable material is added on top of the inlay, and glue and the removable liner are added on the bottom.

Hard tags: When the inlay is converted to a hard tag, it is mounted inside a hard, protective case.

Other formats: inlays can be converted into several different formats by adding materials around the inlay. Other common formats include hang tags, care labels, smart cards, travel tickets, and wrist bands.

Infographic: RFID Label Converting Process

Take a look at a possible RFID label converting process including RF performance inspection to ensure the highest quality of the produced labels

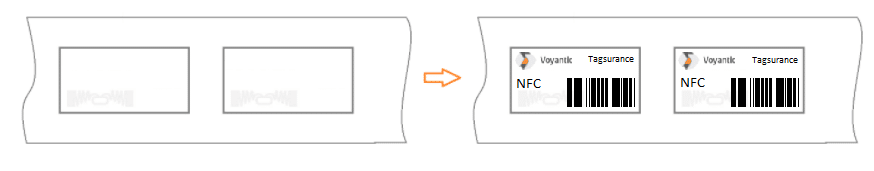

1.5 Personalization

Personalization is the process where data is added to the tag. Sometimes this is called finishing the tag. This includes encoding (writing data to the IC, programming the IC memory) and printing any machine-readable or human-readable optical codes such as barcodes, 2D codes, logos, text, and so on.

1.5.1 Encoding RAIN RFID

The RAIN RFID tag has four memory banks

- TID

- EPC

- reserved memory and

- user memory.

When the tag is encoded, each memory bank has its own purpose. The code which is returned by the reader, and used for example in most inventory counting applications, is EPC memory. In the standard encoding method, the first two words (16 bits) of the EPC memory tell about the type of code used, such as length of the code and used encoding standard. The actual unique code starts at the word pointer 2 and is commonly either 96 bits or 128 bits long, although some applications use also longer codes.

Mostly used standards are Tag Data Standard of the EPC standard family, and Tag Data Standard in ISO standard family.

In EPC Tag Data Standard the first part of the code tells details about the code, the next section is a company prefix, which indicates the owner of the code – usually the manufacturer of the item. And last part of the code is a unique serial number.

Further reading: EPC Tag Data Standard

On-demand webinar series: RAIN RFID Encoding Essentials for Barcode Professionals

1.5.2 Encoding NFC

NFC tags typically have more memory than basic RAIN RFID tags. Common uses for the NFC tags are payment cards, key cards or fobs, travel tickets, and marketing labels pointing to a web address.

Many of the use cases require advanced security features. For example, a payment card or hotel key cannot be cloned just by reading the data from the tag. Using these features requires their own encoding tricks. In marketing, a typical method is to encode a web address, such as www.voyantic.com, and instructions on what a reader device should do when reading a tag with a web address. Many ICs have special encoding commands that automatically program the NFC tags memory in the right way, to the right location, and with the right instructions, if for example the URL programming command is used.

Further reading: NFC encoding

1.5.3 Printing

Many tags have also visual information. Price labels have printed barcodes, company logos, price and product information, and so on. Travel tickets have their own printed information. For the tag to work well, the printed information has to match the encoded data, and most brand owners have strict guidelines for the visual looks.

1.5.4 Cutting, slitting, punching….

Part of personalization is also finishing the physical appearance of the tag. The details depend on the format of the tag. For example in the case of a hangtag, during the manufacturing, the tags may be on a roll, or on a sheet. In the final stages the individual tags are separated from each other, cut into a final format, a hole is punched and a string may be attached.

The personalization process may include many individual tasks and steps. When optimizing the manufacturing, the following points should be considered:

- many tasks in one process and machine vs. own machine and process for each task

- single lane vs. multiple lanes

- exception handling.

1.6 Tagging the item

Tagging or tag placement is the process where the finished tag is attached to an item and taken into use. Some industries, for example, retail, have created standards on how tags are placed on different items. The purpose of the standards is to help the user. At a point of sale, they handle similar items from several manufacturers, and having the items tagged in a standard way, ensures smooth operations.

Companies can organize tagging in different ways. Usually, in pilots or test projects, tagging is done on-site as a part of the project. For example, every item in a warehouse is taken from a shelf one-by-one and a tag is manually attached to the item. The process is very labor-intensive and is not suitable for volume use beyond test projects. In volume tagging, different applicators are used. The applicators come in several formats and volumes depending on the type and volume of the item that is being tagged.

In retail or supply chain projects the goal is usually to enable source tagging. This refers to tagging made by the item’s manufacturer, as a part of the manufacturing process. In this case, the tag is usable from the beginning for the manufacturer, for transportation, for supply chain companies such as distributors and retailers, and even for end-users. Each of them can benefit from the RFID technology and achieve more accurate and efficient operations. When the tag is attached by the manufacturer, there is no need to alter or open any packages after the manufacturing. This minimizes any damage risks and removes the need for possible double work.

Service bureaus are commonly used. The service bureau is a service provider located close to a manufacturing site, possibly even in the same premises. They personalize (and possibly convert) the labels as needed, and may also attach the tags to items. This division of responsibilities enables manufacturers to focus on their core competencies, and service bureau to focus on the RFID, NFC, and personalization.

Increasingly, the tags are embedded in items. A typical example is a RAIN RFID-enabled car tire. A label or such would not survive in the use, and the only way to enable long-term RFID use is to embed the tag inside the tire. This way it can be used over the tire lifetime for tracking maintenance, used in warehouses, and in sharing recycling costs between manufacturers.

2. Quality testing in smart tag manufacturing

RAIN RFID and NFC tags are also products on their own, even if they are at the end attached to other items. In manufacturing, the tag’s parameters such as efficiency, capacity, speed, and quality are as important as with any other product.

In the case of RAIN RFID and NFC, the manufacturing quality is practically seen as a variation in the read range and readability. If a hotel key card manufacturing quality is insufficient, the users have occasional problems in opening the doors. If RAIN RFID apparel hang tags’ quality is not good enough, the read range varies and items are missed in inventory counts. The level of quality should be given by the end-user or derived from the use case – how much a read range or reading experience can vary before the system starts to fail, for example when inventory accuracy decreases or travel ticket errors are too frequent.

Further reading: RAIN RFID read range

A quality management process should be established for tag manufacturing. There should be goals for the quality, quality must be measured, and when the goals are not met, corrective actions should be taken. Processes and practices, such as ones described in ISO18000 quality standards and 6 sigma programs, can be used also with RAIN RFID and NFC.

In practice, the quality can be tested in-line in the manufacturing process, off-line in a separate test process, or can be based on samples. The quality program has to be designed to match the manufacturing process. When the process is correctly planned, the outcome is good and quality testing does not slow down the production process.

Further reading:

- Best Practices for RAIN RFID Label Quality Testing

- RAIN RFID production quality

- Minimizing smart label quality variation

Some common good practices are

- Test 100% of the inlays in IC attachment. This is where the quality baseline is created, and real-time feedback is the key to minimize any losses in case of manufacturing errors. A good test ensures that each tag works as specified, and the exact quality (in practice sensitivity) of a tag is measured, and TID or UID is recorded.

- If good test data is available from IC attachment, the shorter and faster test can be used in converting. A typical test method would be a point test checking that the tag works as specified.

- And again, if good data is available from earlier processes, just a quality verification (checking that the quality has not changed) may be enough in personalization.

- Commonly these in-line tests are complemented with off-line sample tests, especially when the organization is different in different process steps. Off-line testing is for example used in incoming quality inspection: “keeping the supplier honest”.

Infographic: Introduction to Smart Label (RAIN RFID & NFC) Manufacturing Process

Download the infographic to get a quick overview of RAIN RFID and NFC manufacturing process steps, quality considerations and value chain position considerations, as well as data encoding.