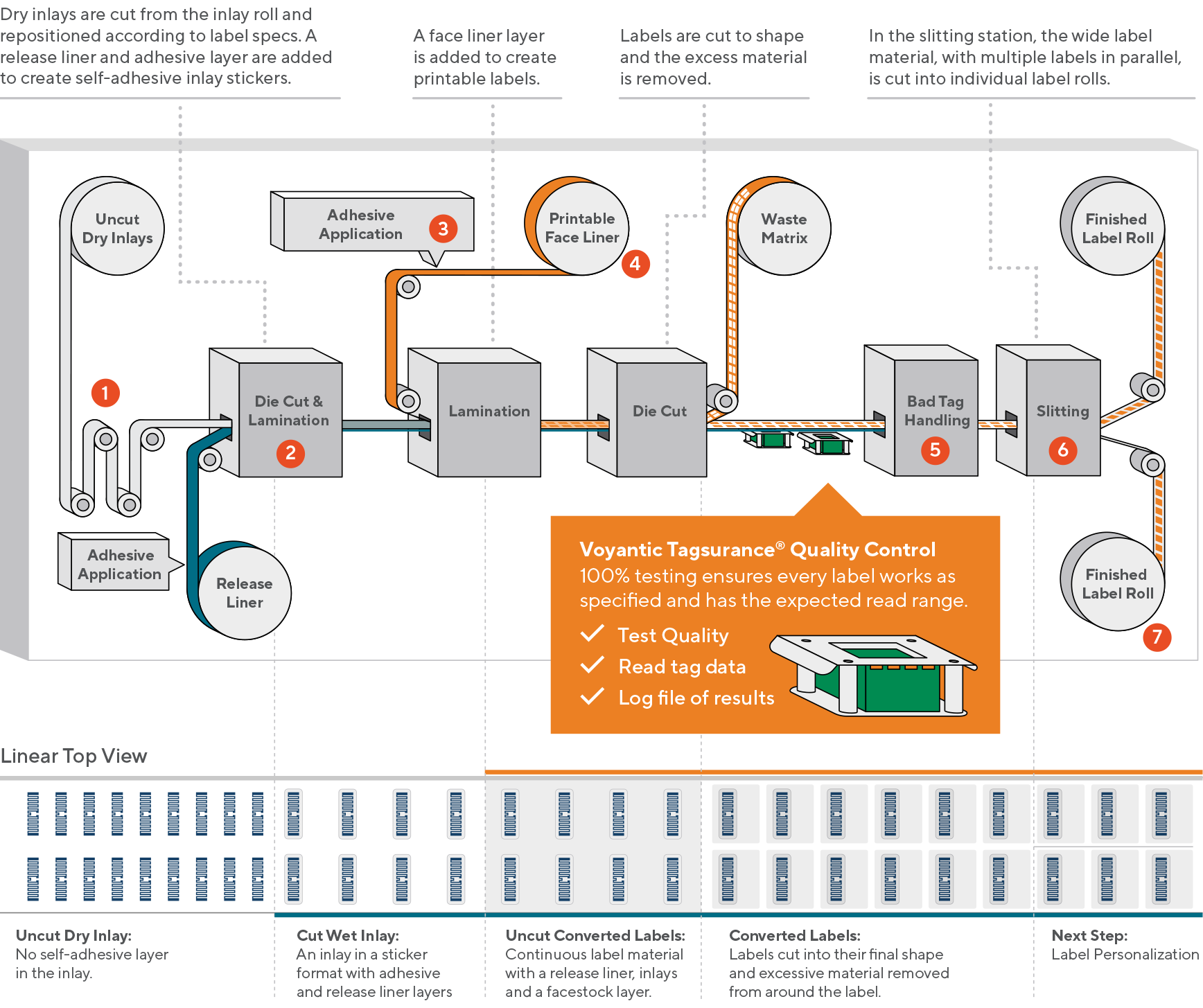

RFID Label Converting Process

Here’s a look at a possible RFID label converting process including RF performance inspection to ensure the highest quality of the produced labels.

Considerations for Consistent Quality

- Tension Control

Wrong inlay roll tension can cause IC malfunction. If the roll is too loose, it can slip and break the IC. A too-tight coll can potentially cause the IC to crack, or the IC antenna joints to fail. - Inlay Placement

Ensure that inlays are placed in the same position on the label. Consistent placements ensure accurate performance test results.

- Adhesive Coating

Ensure even coating of adhesive for consistent output. - Materials Consideration

Do not use metallic foils for face liners. Metals affect the RF performance of the label. - Bad Tag Handling

Typically, when a label’s RF performance does not meet performance requirements, the label is marked with a bad tag marker on the production line. The roll information includes a count of good tags and a note of marked bad tags. Sometimes the out-of-specs tags are crushed or punched. This destroys the tags and prevents them from getting accidentally into use. If customers require rolls with only perfectly working tags (100% rolls), the failed tag must be removed, and possibly replaced with a good one. this process is often called roll doctoring and can be done post-process in a separate rewinder machine or inline in the converting machine. - Slitting Accuracy

Pay attention to slitting accuracy to avoid accidentally cutting through the inlay antenna.

- Rewind Tightness

Pay attention to rewind tightness to prevent damage to the RFID tag on the label. - ESD: Electrostatic Discharge

For dry inlays that don’t have any material on top of the IC, ESD protection should be considered.

Quality Control Brings Visibility into Production

Voyantic Tagsurance 3 is a complete system for measuring the performance of RAIN (UHF) and HF RFID inlays, tags, and labels throughout the production process. With Voyantic Tagsurance 3, it’s easy to verify the job is done right. That’s why Voyantic is the industry leader in RFID label production quality control.

Additional Considerations

Trigger Sensors

Trigger sensors are used to accurately detect when a label enters the system to make sure the RF tests are performed exactly at the right time for each label. Getting the triggering to work correctly is crucial – very often problems with the system are due to issues with triggering.

[Blog] Learn how to get triggering right >

Splicing Station

When a quality control system detects a bad tag on the production line, the bad label can be stopped at the splicing station where it can be removed. A splicing station typically includes a flat surface where the label web can be clamped to hold it in place. Then, the bad label is cut and removed, and the label web is taped back together to continue the production of 100% working label rolls.

On-Demand Webinar:

RAIN RFID 101 for Label Converters

Watch the 60-minute crash course on RFID essentials

You are in the label converting business, and your customers are now asking for RFID added to your label products.

Great! Why are your customers talking about RFID now? What specifically is RAIN RFID? How can you get going? What do you need to consider to avoid claims and rework?