Enabling the Digital Identities of Items for IoT

RAIN RFID is a wireless technology that connects items to the internet, enabling identification, locating, authentication, and otherwise engaging with the items.

RFID-tagged items are essential parts of RAIN RFID systems. The importance of the RF performance of the tagged items is often overlooked in RAIN RFID system design. Items are not considered technical parts of the systems in the same way as tags, readers, antennas, and software. However, looking at the RF performance of the tags when they are attached to the items is important. These Items are what RAIN RFID systems identify, locate, count, control, and otherwise engage with. And tagging an item enables these system actions.

Good RF performance of a tagged item is critical for the RAIN RFID system to work well. And good performance is achieved by properly designing and verifying the tagging.

This article discusses RAIN RFID-tagged items as technical components of RAIN RFID systems.

RAIN RFID Tagged Item

Within RAIN RFID systems items should be understood very broadly. An item that is being sold in a retail store is an obvious example. But, anything that is tagged in a RAIN RFID system becomes a “Tagged Item” – for example, a hospital patient wearing an RFID-enabled bracelet is a Tagged Item in a RAIN RFID system.

Good and consistent RF performance of a tagged item is important for a RAIN RFID system to work reliably.

Tagging an Item – Development

Tagging is an act of attaching, mounting, or embedding a RAIN RFID tag to an item.

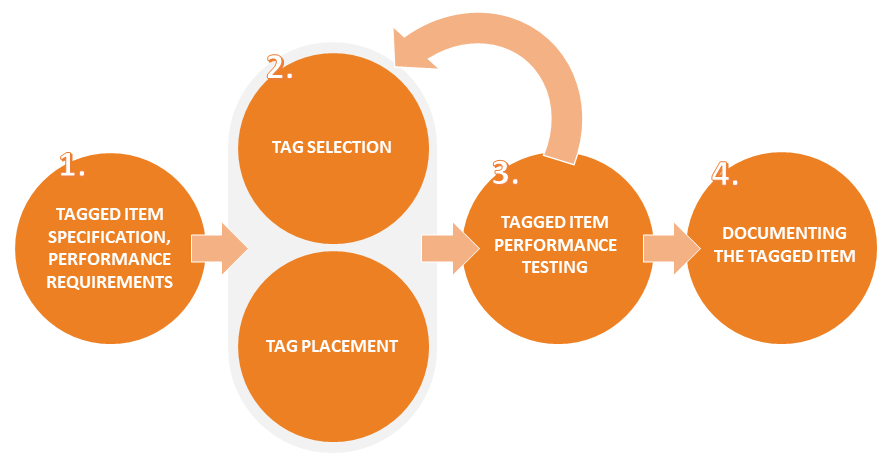

The development project for tagging includes

- Defining tagged item specifications, including performance and quality requirements

- Tag selection

- Tag placement design

- Verifying and documenting tagged item RF performance

Tag selection and designing tag placement are repeated iteratively based on performance results until the performance requirements are met.

Tagged Item Specification – Performance Requirements

Tagged Item specification, aka specifications for tagging, can cover several technical topics:

- Tag data – encoding

- Durability

- Mounting/attachment-related requirements

- Production process-related requirements

- RF performance requirements

- RF quality (performance consistency) requirements

This article focuses on a tagged item’s RF performance and RF quality.

Performance requirements describe the readability of the Tagged Item in measurable and verifiable format. Typically the requirements include in some format from how far and from which angles the tagged Item should be readable with an RFID reader.

A good method for developing the performance requirements is to start from the use case, and then describe the requirements in a measurable format.

RAIN RFID Use case

Performance requirements definition starts by understanding the use case at a practical level, such as:

- How the items are placed in reading locations

- What kind of RAIN RFID readers are used

- What are the required reading distances and angles

- What is the required reading accuracy

- Is it enough to consider single items, or should tag populations be considered?

Use Case Specification Example

The following example describes use case requirements and how those translate into performance requirements that are measurable.

| Use Case | Performance Requirements |

|---|---|

| A packaged item must be readable with 100% accuracy when it passes a gate reader with a 150cm distance between the gate antennas. Items are transported globally. A single item can be carried through the gate. A carried single item can pass the gate in any position. Item(s) can pass the gate on a pallet, a maximum of 8 items on a pallet. The top side points upwards and the package side points towards the gate reader when between the gate antennas. | A packaged item must be readable from a 75 cm distance from the side, at any rotating angle with 33dBm radiated power reader equipped with a circular polarized antenna, at any frequency from 865 to 868 MHz and from 902 MHz to 928 MHz. (Note: 33 dBm reader power would be from the reader datasheet; the mentioned frequency ranges cover global RFID frequencies) The readability requirement is achieved when the tagged item sensitivity is 3.7 dB or better in any rotating angle. (Note: at worst case tag is 75cm from the antenna. 75 cm free air path loss at 928 MHz (highest) is 29.29 dB. 33 dBm (reader power) – 29.29 dB = 3.71 dBm) |

| This use case description is useful for understanding the application and reasoning the requirements. But on its own, it cannot be used as a measurable requirement. | The 75 cm read distance can be tested in a practical setting. The tagged Item sensitivity in dBm can be measured in the design lab and verified in tagged item production, where an actual gate reader is not practical. |

These technical definitions are measurable and can be easily used in tag selection and tagging design. Tag alternatives and tag placement alternatives can be tested against these technical specifications using the Tagformance Threshold Sweep, Orientation Test, and the Read Range test features.

Tag Selection

The tag selection process includes three steps.

- The first step in tag selection is done without testing. The initial tag selection criteria is based on the tag format and any possible special features required by the application. For example:

- What should be the format: pressure sensitive label, hard tag, on-metal tag, hang tag, wristband, ID card, key fob, windshield tag,…

- What size of tag can be used?

- Is larger than normal memory needed, sensor functionality, special security,…?

- The next step in narrowing down the tag options is to find tag candidates that most likely meet the performance requirements. This selection is made by testing a long list of tag candidates with reference material corresponding with the material of the item, such as cardboard if the tag would be placed on a cardboard package of the item.

The fastest way to narrow down the tag selection is to use the threshold sweep measurement. The results are an easy way to find tags that have suitable tuning, and the best read ranges among the tested tags. - The third step in narrowing down the list of potential tags is to check the orientation patterns, test the proximity tolerance, and run any other relevant tests which may vary depending on the use case definitions and technical performance requirements.

A more complete example of tag testing is shown in a video about tag characterization:

Tag Placement Design

Selecting tag placement is another essential part of tagged item design. Some applications may have standards, industry practices, or other guidelines advising on tag placement. For example, in apparel retail tag placement follows almost always the GS1 US Apparel & General Merchandise Implementation Guideline, Format and Placement for the Electronic Product Code (EPC) document.

The package or item design, typical position, and other physical features may limit the choices for tag placement. In many industries, tag placement is recommended to be indicated with an RFID or EPC logo on the package or the item. The possibility to place the logos may be another limiting factor.

With the available placement choices, performance tests provide the final guidance. Typically these tests are combined with final tag selection tests: the tagged item is tested with a few different tag and tag placement combinations to find out which combination is the best one for the item.

Watch the video below for a more complete example of tagged item testing, including tag selection and tag placement selection.

Tagged Item Performance Testing

Tagged Item performance testing is used in the final steps of the tag selection and tag placement design. The result of the test verifies that performance requirements are met.

Testing a single Tagged Item

The most useful tests for evaluating the tagged item performance are:

- Read range test: The test can be used for finding out the reading distances of the tagged item with different readers, without a need to actually separately test with those readers.

- Orientation test: The test shows the readability of the tagged item from various angles.

When these tests are done in relevant reading angles with relevant reader data, the results typically give very good information for both final tag selection and tag placement selection.

Tag population

Sometimes tagged items are stored, transported, or used as multiple items in close proximity to each other. With dense tag populations, some further tests are needed.

In dense tagged item populations close-by tags affect each other’s performance. The use case and performance requirements should also indicate a need to test a tag population, for example: “A box/pallet/tray of tagged items should be readable ….”

The readability of the tag population is tested with Tagformance Pro’s Population Analysis feature.

Video below shows a more detailed example of analyzing tag population.

Documenting the Tagged Item

When the tag and tag placement are selected for an item, the outcome should be documented.

Good documentation includes at least the following information:

- Tag selection limits ꟷ Tag frequency range (RAIN RFID), IC features, shape, size, format,…

- Tag placement ꟷ A picture is an easy way to show placement. Also, the mounting method may be relevant

- Tagged item performance. This is where the GS1 Tagged Item Performance Grade comes in handy. When the tag selection is done, and tag placement is chosen, the item can be run through a Tagged-Item test with Tagformance Pro. The result gives the performance grades in short and handy formats and eliminates the need to describe performance in complicated technical terms combining angle degrees, decibels, centimeters, megahertz, etc.

Manufacturing a Tagged Item

Adding a RAIN RFID tag to an item is automatically also an addition to the manufacturing process. The tag must be applied to or embedded into the item. This may need separate applicator machines or modifications to existing manufacturing lines.

A tag must also be encoded, in other words, the correct data needs to be stored in the tag before it becomes usable. Either a tag is encoded before it is applied to an item, or the tagged item is encoded after the tag is attached.

Quality testing and data verification are process additions that naturally follow the tagging process.

At minimum, you need to consider:

- What happens if a bad-quality tag is placed on an item? If a poor performance tag causes the entire item to be discarded, an incoming quality inspection may be a cost-efficient solution.

- Is there a risk of damaging the tag in the production line? An RFID quality test may be beneficial at the end of the manufacturing line.

But how do you determine the right place for quality testing within the manufacturing process? If you test at the beginning of the process, you can catch the non-performing tags early on, minimizing material waste and extra work. But if you only test early in the process, you will not have performance data for the finished tagged item.

Testing at the end of the process will give you the performance of the finished tagged item, but there is a risk of having to discard the entire item, not just the component, if the embedded tag is not working within the specified requirements. Sometimes the optimal solution may be to test in the middle of the process or to utilize multiple test points. The most suitable testing approach depends on the quality control strategy, the nature of the tagged item, and the tagging method.

Voyantic Tagsurance would be the default system for quality testing in manufacturing lines. The system is easy to integrate into almost any machine, but obviously many details need to be considered. After all, an item can be almost anything and manufacturing lines are different from each other.

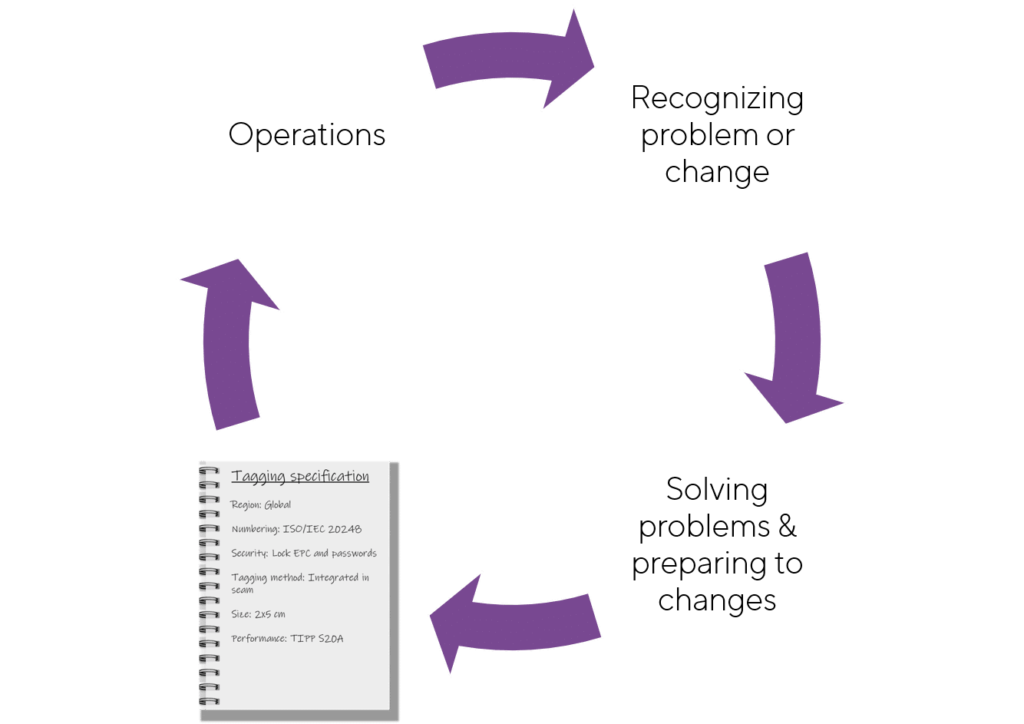

Maintenance and Continuous Improvement

As in any part of a RAIN RFID system, it is good to include item tagging in a continuous improvement cycle.

RAIN RFID technology develops. There will be new readers possibly changing the requirements. New potential tags will become available. New use cases will emerge for the tagged items. All these may prompt a need to complement or change the specifications.

Something may go wrong. If a tagged item does not work as intended there should be a way to check what the problem is:

- Is the tag placement as specified?

- Is the correct type tag used?

- Is the tagged item performance as specified?

- Possibly the use case requirements have evolved and specifications needs to be modified.

Learn more about continuous improvement cycle applied to RAIN RFID tagging in our blog.