3 Resources for RFID Smart Label Converters

The RFID Label Market is Growing

RFID tag sales grow at an average of 25 % annually, which is a significantly faster rate than the traditional label market growth. IC shipments will rise to 88.5 billion annually by 2028.

More and more label converters are entering the RFID market. But to succeed in RFID, education and expertise in the technology is required.

Below you can find 3 educational resources to help you get started. If you have any questions related to RFID technology or would like to receive similar resources in the future, send us a note here ›

1. Webinar Series for Label Converters

Watch Part 1 – RAIN RFID Technology 101 for Label Converters ›

You are in the label converting business, and your customers are now asking for RFID added to your label products.

Great! Why are your customers talking about RFID now? What specifically is RAIN RFID? How can you get going? What do you need to consider to avoid claims and rework?

Watch Part 2 – Panel Discussion: RAIN RFID Label Converting Essentials ›

Tune into the expert discussion on RFID converting practicalities, customer expectations, and market outlook.

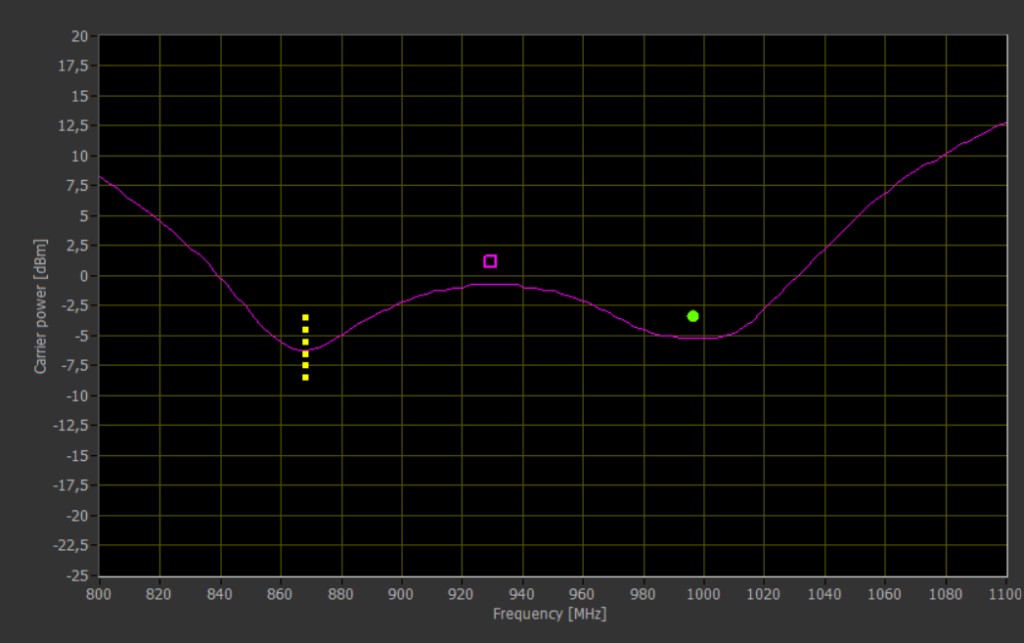

2. Blog Post: Why Label RF Quality Matters? Framework for RFID Tag Quality

The quality of RFID tags and labels boils down to RF performance – how consistent is the performance compared to the RFID tag specifications?

This post includes a framework that describes the levels of defining smart label RF quality, from design quality to documented production quality control.

3. Blog Post: Best Practices for RAIN RFID Label Quality Testing

RAIN RFID, aka UHF RFID aka EPC RFID, is the technology used in connecting billions of everyday items to the Internet. In 2020 RAIN RFID tag volumes exceeded 21 billion, and in 2021 volumes reached over 28 billion. We are seeing this strong growth continue. At the same time, RAIN RFID users have started to pay more attention to their RFID label quality.

Read the post to learn the current best practices in RFID quality testing.

Let’s Talk!

How can we help you?

We would love to hear about your challenges and if you have any questions on RFID. Or if you would just like to receive future resources and webinar invitations, let us know!