One of my customers in Taiwan is developing battery-assisted passive (BAP) tags. He called me recently and asked why the read range that they reach with their RFID reader is only a quarter (1/4) of the distance that they measure with their Tagformance RFID measurement system. I answered him with another question: “Do you know your reader receiver sensitivity…?”

What Is a BAP Tag?

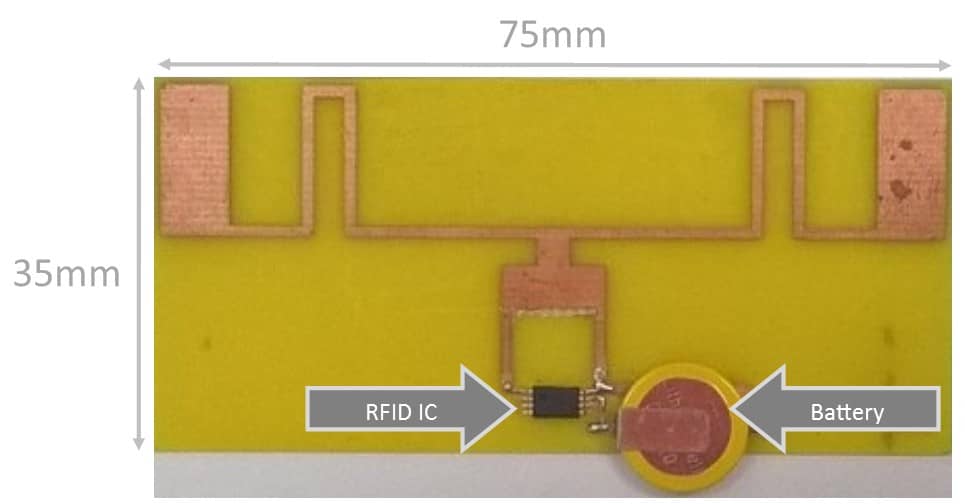

A BAP tag has an on-board battery to power its IC, but like a passive tag, it does not have an active transmitter. BAP tags are generally used to reach longer read ranges than what passive tags can provide, or for logging some physical quantity when a reader is not present. As known, the typical limiting factor for the read range of a passive tag is the forward link. In other words, the read range of a normal passive tag is determined by how far the passive tag can be powered or activated, i.e., the tag sensitivity is the limiting factor. Therefore, by default designing the passive tag to receive power from an on-board battery as a BAP tag, read range could be increased.

However, since the on-board battery is only used to power-on the RFID IC or to increase the BAP tag sensitivity, the battery does not really increase the tag backscatter power. As a result, the return link will become the limiting factor for the read range of a BAP tag. In order to fully realize the maximum read range of a BAP tag, the reader receiver sensitivity becomes crucial.

The Performance of a BAP Tag

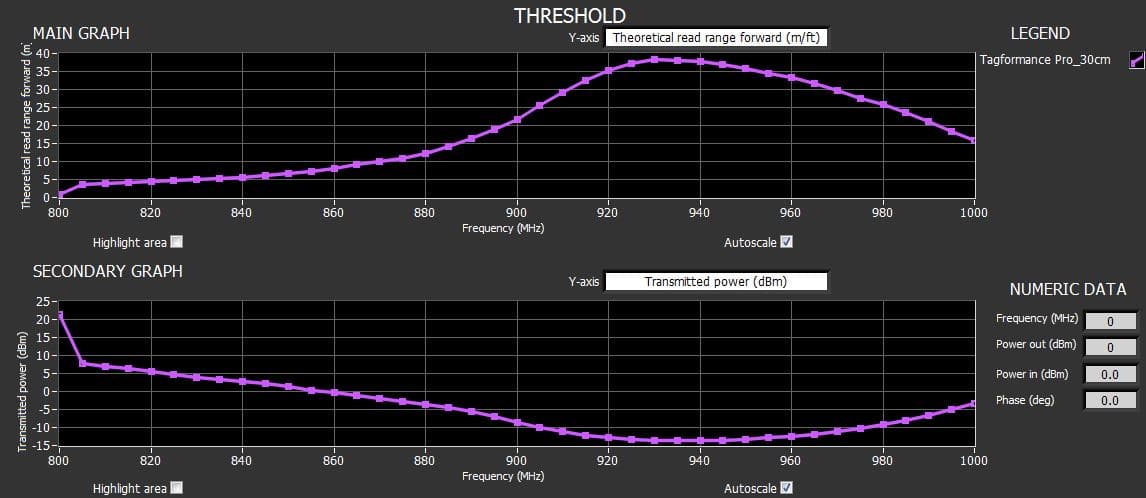

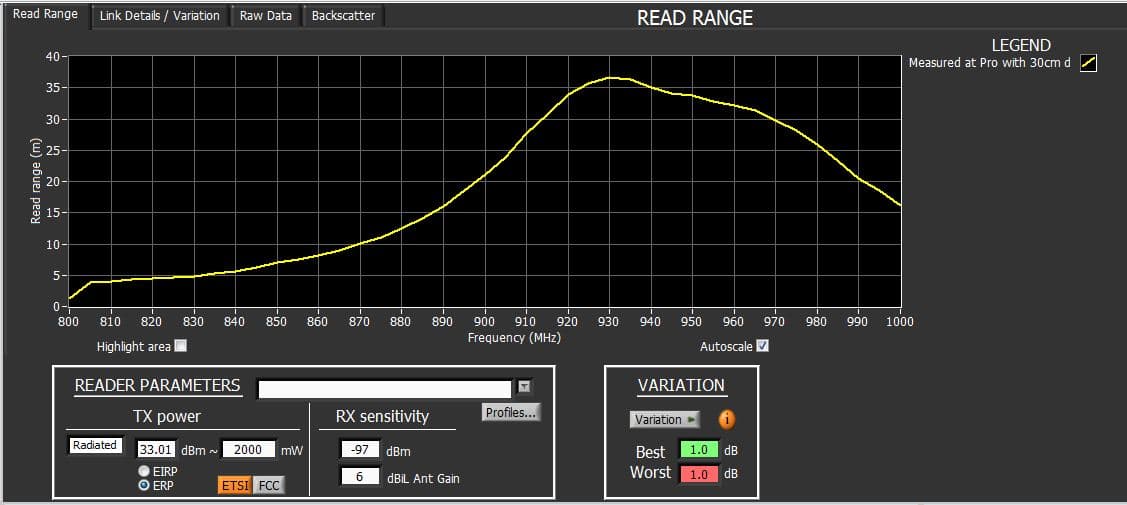

When evaluating the performance of an RFID tag, the starting point is usually measuring the sensitivity of the tag as a function of frequency. The graph below shows the Tagformance Pro’s Threshold Sweep measurement results of one BAP tag. As can be seen, the theoretical read range for this BAP tag is close to 37 meters at 930 MHz. That is a lot; the read range of a good passive tag is around 10 meters.

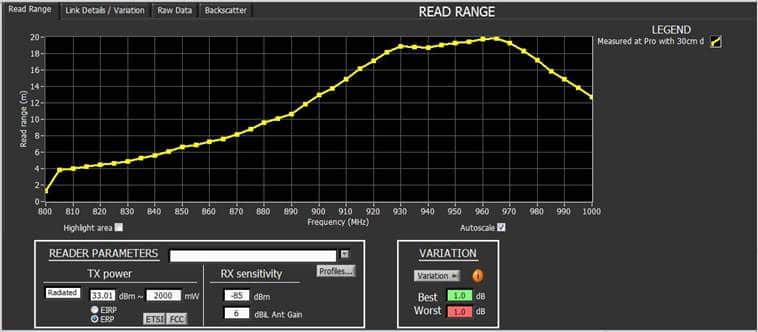

But the forward link read range above is only the theoretical upper limit of the read range that can be reached. Below we use the Tagformance Pro’s Read Range measurement functionality to test the BAP tag with different reader parameter settings. The radiated power is set at 2W ERP. The yellow curve below shows that the read range is about 19 meters at 930 MHz if the reader receiver (RX) sensitivity is -85 dBm.

By changing the reader sensitivity in the Tagformance software, we can see what reader sensitivity would be needed to reach the theoretical read range maximum. This situation is shown in the yellow curve below. The reader sensitivity required to reach the 37-meter read range is -97 dBm.

From my experiences, it may not be easy nowadays to find a reader with the RX sensitivity of -97 dBm. Therefore, in order to reach the read range of 37 meters, I have suggested my customer redesign the BAP tag’s antenna to make the tag having stronger backscatter power and use a higher sensitivity reader if possible.

Reader receiver sensitivity is getting more attention in the RFID market after the increase of tag sensitivity both in BAP tags and normal passive tags. This means that the limiting factor for the read range is the return link. Receiver sensitivity is the key to optimizing the read range. Interestingly, most system integrators and even UHF reader suppliers do not know how to measure the receiver sensitivity.

All blog posts