Recent developments in RAIN RFID technology, markets, and global regulations have made the RAIN RFID an even more interesting technology. I believe that with the RAIN RFID a traditional industry such as tool manufacturing can join the digital revolution. In this blog, I will explain why it is a good time for the tool industry to adopt the RAIN RFID technology and how to get started.

RAIN Is Ready

In 2006, IR DSRC defeated RFID technology and was chosen for the Electronic Toll Collection (ETC) System in Taiwan’s freeways. Six years later, in 2012, Taiwan’s ETC system was migrated from IR DSRC to UHF RFID technology, which transferred the freeways tolling system from a flat-rate and barrier-based to a distance-based and multi-lane free-flow on all of Taiwan’s freeways. ETC application is an example of how the market will correct technology selection with time. The tool industry is now facing a similar choice as ETC in 2006. Let’s hope the right technology is chosen from the beginning.

I started to see some companies providing tool management solutions with UHF RFID technology back to 2010. Frankly speaking, I was in doubt at that time if the market would value such a solution. The cost of adding an RFID tag on each tool was not cheap. Also, having a tag recklessly attached or glued on tools seems inappropriate and not professional as the tag protruded on tools’ surface may affect the tool’s usage and cause potential danger to tool users. More importantly, I did not see UHF RFID was ready for tools management in terms of technology maturity then.

Around 2015, Stanley Black & Decker launched tool management solutions aimed at minimizing the effects of FOD (Foreign Object Damage) and ensuring the right tools are in the right places at the right time. This kind of tool management solution is quite attractive in industries like aerospace, transportation, healthcare, manufacturing, and construction. Though barcode is one of the most widely used methods of tools tracking in today’s market, RAIN technology has many advantages over the barcode. For instance, RAIN enabled tools can be read without a direct line of sight even when the tools are covered with dirt or grease. And multiple RAIN enabled tools can be read at once when they are inside a box or bag. RFID Detection Bag is a good use case.

More importantly, more and more tag suppliers are starting to provide RAIN tags for metallic product applications, like industrial tools or surgical tools. Confidex, Omni-ID, Murata, Xerafy, and Etagsys are examples. Some of them can offer customized RAIN tag for the market. This indicates that the RAIN tag industry is ready to serve the tool manufacturing industry.

Built-in RAIN RFID as Part of Product

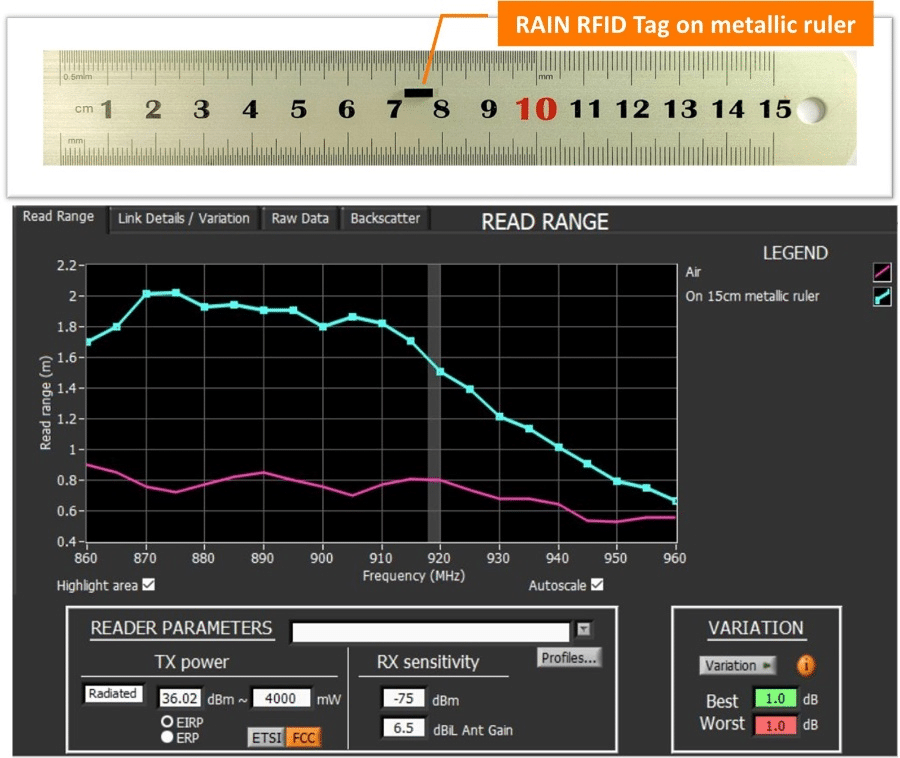

Using the tools’ metallic surface as an extension of the tag antenna to enhance RAIN RFID read range. A quite high percentage of tools are made of metallic materials, which normally play a negative impact on RAIN RFID performance. The below picture shows a RAIN RFID tag’s (6mmx2mmx2mm) read range when it is measured on air and attached on a metallic surface.

This tag is designed to cover Lower ETSI and FCC bands (865MHz – 930MHz). At the frequency around 920MHz, the tag read range is 0.8 meters when measured on air. If we put the same tag on a 15cm metallic ruler, just like the metallic surface of tools, the read range increases almost 100% to around 1.6 meters.

An innovative tag antenna engineer should think about how to integrate the tag antenna into the tools and turn the challenges of metal into the advantages. Besides, instead of labeling or patching tags on tools after they were produced, embedding RAIN RFID tag into tools in design and production stages not only enables seamless tracking of each tool from the factory to the consumer, but it can also prevent people from removing RAIN tag easily.

Global Regulations

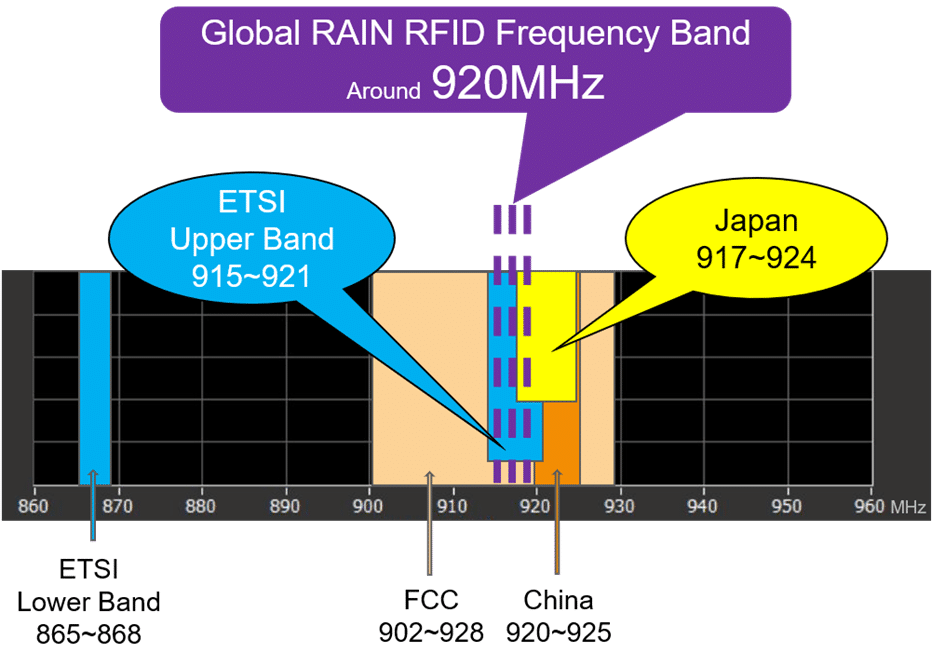

We know different countries have different regulations for RAIN RFID frequency bands. The good news is that Japan had migrated its RAIN RFID frequency band down to 917MHz – 924MHz in 2012. And the European Commission decided to add a new frequency band, Upper ETSI_915MHz – 921MHz, in 2018. By the time of writing this article, about 20 countries in Europe have adopted at least part of the Upper ETSI frequency band for RAIN RFID application. This means that sooner or later, we are going to have a global RAIN RFID frequency band which is allocated around 920MHz. What does it mean for the tool and RAIN RFID industries once the global frequency is widely adopted?

Global frequency simplifies the production of RAIN RFID enabled tools/items. The same RAIN RFID enabled tools can be used and sold worldwide. This will help to scale up production and reduce the cost.

This opens the possibility to optimize tag performance for the narrow frequency band tag around 920MHz. Either tags can be made smaller, or longer read ranges can be achieved, read more from Voyantic CTO Dr. Jesse Tuominen’s blog. Though the variation in the RF performance has a larger impact on read ranges of a narrowband tag than on a broadband tag, fortunately, Voyantic’s Tagsurance UHF has proved to be a great solution in tackling this challenge.

No doubt, RAIN RFID provides much superior performance and potential capability compared to the barcode. However, the initial investment of adopting RAIN RFID technology is still more expensive. And it is true that RAIN RFID is not going to replace the barcodes entirely. In some use cases, the combination of RAIN RFID and barcode can be the optimal solution. But I want to point out: after a decade of market development, technology advancement, the cost decrease of RAIN components plus the global regulation change, RAIN RFID is now a feasible solution for the tool industry.

Benefits of RAIN Enabled Tools Management

I recently visited some tool manufacturing companies in Taichung and asked them what are the major problems that the tool users are facing. Their answers include lost, stolen, and misplaced tools. To be honest, I am a little bit surprised by such answers, but it again explains the importance of tool management. RAIN RFID is the ideal solution to reduce the pain points and inefficiencies. From the tool user point of view, RAIN RFID together with other IoT technologies can enhance tool management, for example:

- Locating and tracking tools become easier

- Improve security and avoid internal/external thefts

- Increase tools utilization and availability due to full visibility

- Minimize the effects of FOD

- Enhance automation of alerts and reports

- Eliminate human error and increase management data accuracy

- Reduce total cost of ownership of tools

The demand for better tool management is apparent, and the market is huge and worldwide. The traditional tool companies surely need to think about how to take this demand as an opportunity and reinvent themselves with RAIN RFID. From my view, tool companies can gain invaluable business advantages if they successfully embrace RAIN RFID into their businesses:

- Differentiate the product from the competition. This is an especially good opportunity for small and medium-sized tool companies to transform themselves from purely manufacturing to IT-driven business.

- Sell more higher-value products than tools, for example, smart carry cases, smart drawers, and tools management software.

- Facilitate sales if the IT system is well designed and developed. Then the customer can check data from smartphone and place order, for instance:

- Data shows XX2 and XX5 are used over 90% of the time, click here and order both.

- Data shows XX4 has not been seen in a month, click here and order a new.

- Every RAIN enabled tool has a unique identification number which can be utilized for anti-counterfeiting and supply chain management from manufacturing to customer.

I am sure there are many more benefits that RAIN RFID can contribute to the tools management applications. I will leave some room for the imagination of the readers. Now let me briefly describe how to implement the RAIN RFID tracking system. There are some possible ways to carry out:

- Tool company makes the whole solution in-house, including the IT system development and tag antenna design.

- Tool company outsources RAIN RFID part to several different professional suppliers who provide software development, tag antenna design, and other components independently.

- Or tool company cooperates with an RFID solution provider to cover all RAIN RFID related tasks.

- Software company develops and sells tool management solutions to end-users.

It does not matter how the tool management solution is built; the performance and the tuning of RAIN enabled tools need to be carefully tested. Otherwise, the readability would be a big issue. And it is necessary to remind new players that commercial UHF reader is unable to verify RAIN RFID performance. After all, the reader is designed for the application, not for tag design and production quality control. SAG’s story in Taichung Taiwan will explain why it is important to utilize the right testing equipment in the R&D and the production line.

GS1 TIPP

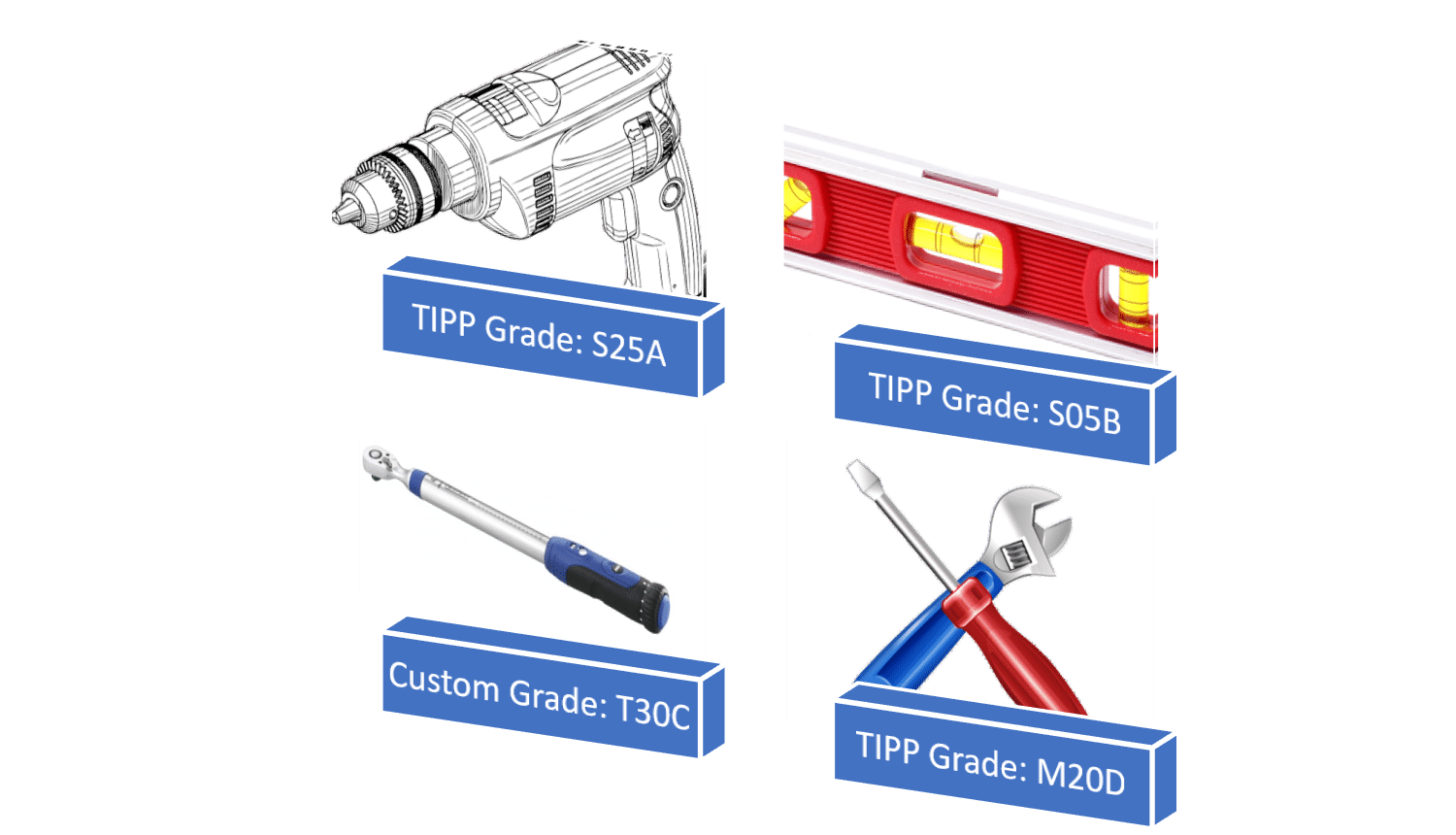

Once the performance of RAIN enabled tools is verified in the actual use case, the tool company can consider applying GS1 TIPP [Tagged-Item Performance Protocol] to streamline RAIN enabled tools specifications. GS1 TIPP is a RAIN RFID grading system developed initially for the supply chain management in retail, but it can be applied outside retail to scale up RAIN RFID applications across industries. Currently, there are fifteen TIPP grades, and tool company can select the grade(s), which can reflect the RAIN enabled tools’ minimal performance requirement. By doing this, it will simplify the communication among tool company, solution provider, and tag supplier. After all, grading is a much more efficient way to define the RAIN enabled tools’ performance. In case the existing grades do not meet the performance requirement, the tool company can submit a new performance grade to GS1 for validation or even create a custom grade.

In addition, the tool company can use the grade to source RAIN tag or RAIN enabled tools from several different suppliers if the specified grade level, tag size, and tagging method are met. GS1 TIPP also gives RAIN tag suppliers more flexibility in how they design the tag. This will encourage the tag supplier to be more innovative and creative to design the products to maximize the business benefit. Finally, any company can build its TIPP testing lab based on GS1 guidelines, and operating GS1 TIPP testing is easy and straightforward. This will help the whole tool industry to scale up the deployment of RAIN RFID technology.

Voyantic is the only company in the world specializing in performance testing systems for RAIN RFID and NFC tags from R&D to manufacturing. If you have any questions about managing the quality of RAIN enabled tools, feel free to contact us.

All blog posts