When talking about high-end RFID performance testing solutions, I sometimes face the situation, where my customer is struggling to find room for the investment in their budget. After some return on investment (ROI) calculation, the case typically looks much brighter.

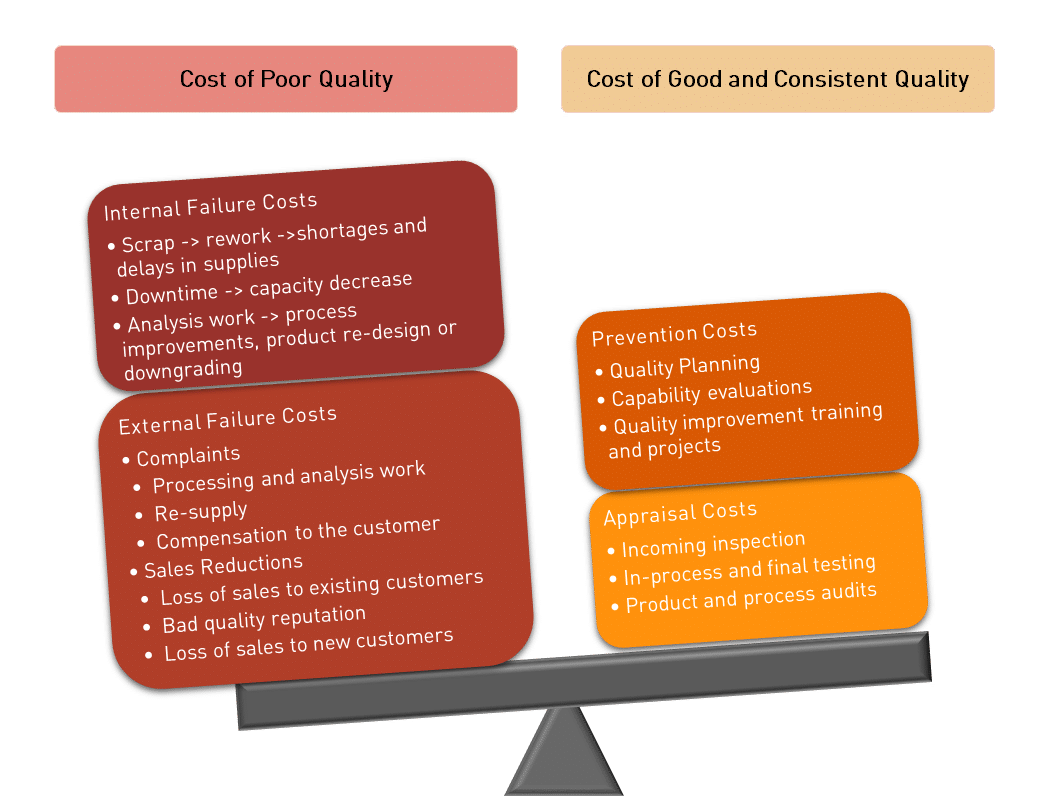

If we look at the overall quality cost structure in UHF tag manufacturing, I will dare to claim that, in many cases, even a single batch of poor quality can justify the ROI for decent RFID test equipment. The challenge here is though that the costs of being able to provide excellent and consistent quality are directly addressed to the production. In contrast, the charges induced from poor quality are inconspicuously scattered all around the corporate structure.

Where do I base the claim? Let me show you!

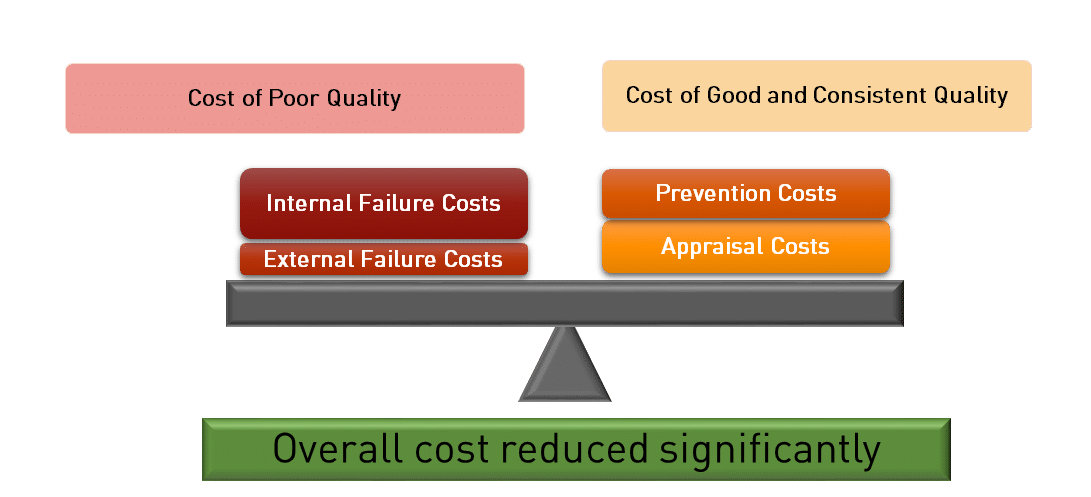

First of all, to lower the cost of poor quality, you need to invest in preventing failures and maintaining excellent quality. The great thing here is, though, that you get much more than your money back. If done right, each penny you invest is multiplied as savings in failure costs. This is how you balance the scale and minimize your total costs.

Let’s Do Some Math!

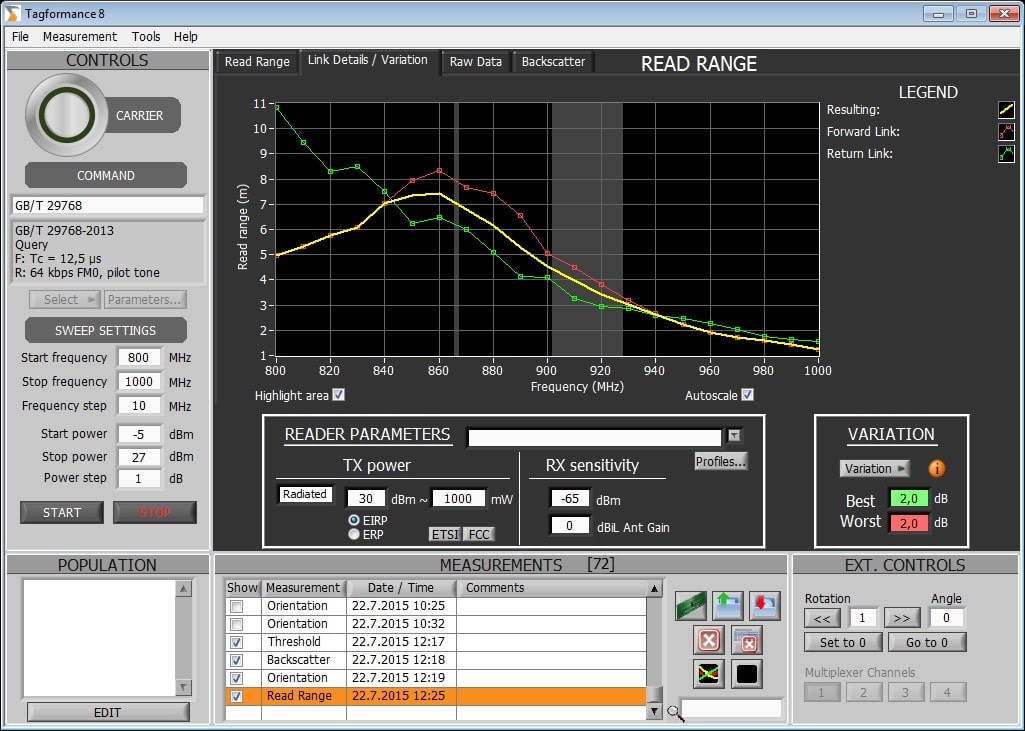

When a quality issue is found in the production, how much does it cost for an engineering team to troubleshoot, or a machine to stand by waiting for the next production batch to be started? I’m sure you know the figures better than I do, but what I do know is these problems take some hours to be solved, sometimes even days. I also know that the one-hour machine downtime in chip attachment makes at least 10 000 tags less manufactured. For a label converting process, it may be ten times more.

What if the problem was not detected when manufacturing the tags, but in an inspection process that was done on the batch afterward? How big is your typical batch? 100 000 tags? 5 000 000 inlays? In the worst case, you need to multiply that with the number of batches produced and with material costs per tag, and add on top of the engineering work and machine downtime.

Ok, now you just need to rework the whole batch, which means again capacity loss, as the machine time is used to reproduce what already was supposed to be delivered. The ball keeps rolling, and you’ll end up with shortages in your next deliveries, delays that cause inconvenience to the customers, and a headache to the management, sales, and customer support. So, just add up the machine time for rework, management, and support time, as well as customer dissatisfaction with the earlier equation.

Now, we are starting to talk about costs that are far more difficult to quantify. Customer satisfaction…

What if the defected batch didn’t remain as an internal issue? What if it reached the customer, who is struggling now with problems in his application? Now we’re starting to talk about external failure costs, which are not only harder to be measured, but also induce secondary effects and costs, like bad quality reputation. I know, impossible to be quantified. But if you just add the management cost due to the complaints and troubleshooting with the customer involved, and forget the fact that the customer may end up ordering his next tags from another supplier, we still have a significant pile of costs due to poor quality. Now would you believe me when I’m saying:

You Need to Balance the Scale to Minimize the Overall Cost of Quality

Unlike the above figure may suggest, the equilibrium point here would not necessarily be where the cost of poor quality equals the cost of good quality. The equilibrium point is reached when the efficient investments in the price of excellent and consistent don’t return more than their value in the costs of poor quality.

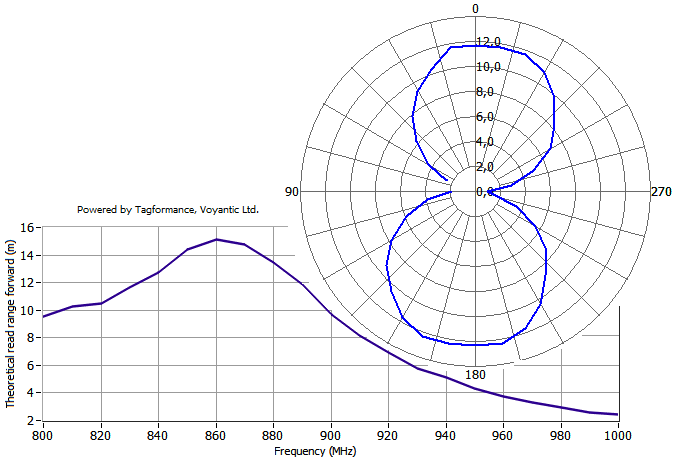

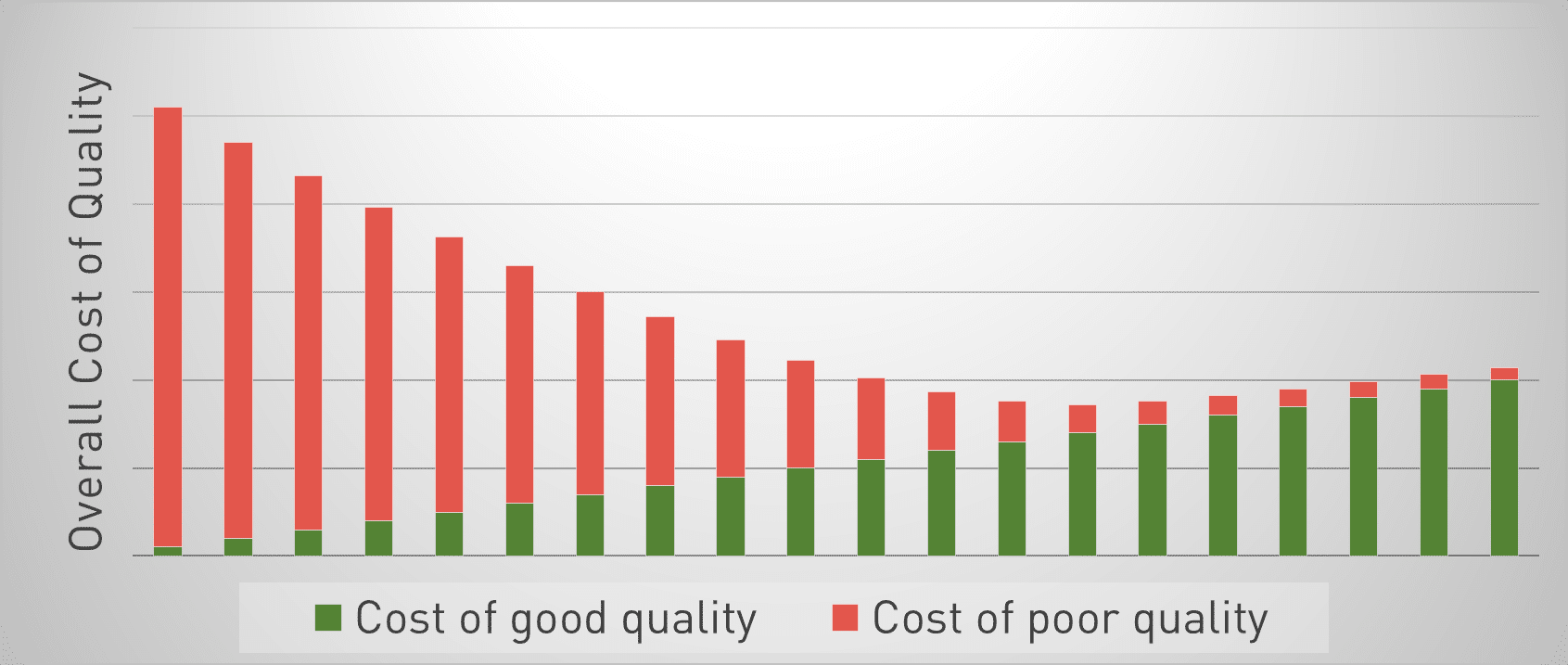

The graph below would represent an example situation, where the costs of good quality are linearly increased, resulting in considerable reductions in the price of poor quality at first. Eventually, the point is reached, where further improving the quality appraisal and failure prevention costs will not lower the failure costs as much.

If you calculate with your figures the overall cost for providing just a single batch of UHF tags with inferior quality to the customer, would you agree with me that these costs are just too high to accept frequently, or at all? This approach is only the tip of an iceberg. What eventually will happen, if the quality continuously keeps failing to meet the customer expectations, is you start losing business, surreptitiously, but deterministically.

Quality Reputation – Hard to Estimate, Easy to Forget

The quality reputation is easier to ruin than to be built. Building it from scratch takes time and effort. Trying to gain customer trust without hard evidence based on measured facts is challenging. Still, if you’re able to quantify the quality, as well as prove the quality is consistent, you’re in a wholly different position to win the customer.

We have various examples of customers who have taken the UHF tag quality seriously, all the way from design to production. There are customers like Michelin, who have decades of experience in manufacturing and quality control. They have the same approach in case of any new technologies. Why ruin the quality reputation you have successfully built for years? With Michelin, we worked on something a bit customized to be able to test tire tags that are very heavily over-tuned. Check out this interesting case study:

Michelin — Tire Tags with Consistent Quality

What kind of figures did you come up with on your overall cost of quality? Would you like to talk more about balancing your scale as well? Please contact us, and let’s figure out how we could lower your quality costs and increase your profitability! For the first 20 people to contact me, I promise to make free of charge tag measurements.

Solutions for RFID productions

All blog posts