In 2021, RFID with sensing technologies continued to be a major research area. The COVID-19 pandemic was also seen in RFID research topics.

Plenty of interesting research papers were published and, unfortunately, I can only introduce a very limited selection of the research topics.

Sensor tags – sci-fi brought to reality

RFID combined with sensing continues to be the overwhelmingly most common broad research area in RFID. But research has clearly moved beyond the traditional sensor tags. Some of the described ideas and methods seemed more like sci-fi than science.

Sensing Covid-19

Covid-19 has inspired some research papers, and practical RFID-based solutions are being developed to help in fighting the pandemic.

- A method is introduced for monitoring facemask filtering capability: Sensorized facemask with moisture-sensitive RFID antenna

- Another timely paper introduces use of RFID tags in monitoring decease agents by detecting their physical and chemical fingerprints: A Plug&Play flexible skin sensor for the wireless monitoring of pandemics

Monitoring structures and machinery

Measuring and monitoring the condition of structures and equipment was another topic area for RFID research last year.

- A method is introduced for detecting surface cracks. It is aimed for monitoring the integrity of large structures: Passive Wireless Dual-Tag UHF RFID Sensor System for Surface Crack Monitoring

- Another paper experiments with aluminum structure crack detection and characterization: Passive Ultra High-Frequency RFID sensor with reference tag for crack detection of aluminum alloy structure

- This paper introduces a method for monitoring the condition of chemical industry equipment with the help of RFID: RFID based Predictive Maintenance System for Chemical Industry

RFID sensors in medical applications

Combining RFID, sensors and medical diagnostics pushes biomedical sciences to a new level.

- Aging can cause micro-cracks in implanted prostheses. A paper titled “A Fractal-RFID Based Sensing Tattoo for the Early Detection of Cracks in Implanted Metal Prostheses” introduces a method that uses RFID IC, a space-filling curve antenna, and backscattering to detect the microfractures before harm is done.

- This paper introduces an alternative method for time-consuming X-rays, MRI scans, and CT scans for detecting deeply hiding infections that are a common thread with implants: Antennifying orthopedic bone-plate fixtures for the wireless monitoring of local deep infections

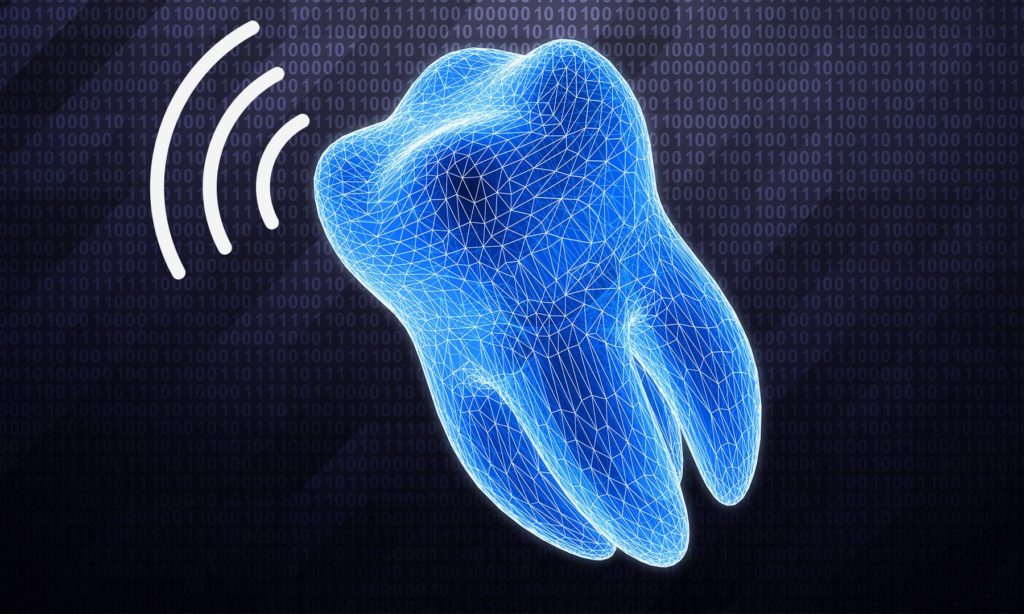

- Another method for early identification of inflammations is introduced in this paper: “Cyber-Tooth: Antennified Dental Implant for RFID Wireless Temperature Monitoring”. In the method the entire dental implants crown is transformed into a dipole antenna. Is this a first step to realize Lucy’s (from I Love Lucy) radio in a tooth?

- A doctoral thesis, titled “Far-Field Backscattering Brain Implant Communications: Antenna Design Methodologies and Performance Validation”, gives a broad view on advances using RFID in monitoring brain activity. Will heartbeat monitoring watches and sleep monitoring rings be followed by brain monitoring for everyone?

Wearable tags, miniaturization and hard to tag items

Textile, yarn, and wearable RFID continue to be another common research topic.

- This paper introduces graphene-based antenna in NFC tags that are used close to the human body – for example in transportation tickets and key fobs: Wearable near‐field communication bracelet based on highly conductive graphene‐assembled films

- A method for improving the production of RFID in textiles is proposed in this research: “Textronic UHF RFID Transponder”. In the proposed method a small dipole antenna couples with an RFID IC without galvanic connection.

The stretching of fabrics is an issue for common RFID tag antenna designs. This paper introduces a way to create stretchable antennas suitable for textiles: Stretchable Textile Yarn Based on UHF RFID Helical Tag.

There are also several papers published around the topic of making ever smaller tags with higher read ranges, and using them to tag, for example, metallic objects:

- Small Wideband Antenna for On-Metal UHF RFID Tag Design

- On Increasing of Read Range of Miniaturized UHF Tags

- Compact Ring Antennas with High-impedance Line Loaded with Distributed Inductors for On-metal Tag Design

- [Compact Metal-Mountable UHF RFID Tag Antenna with Two Large C-Shaped Slots for On-the-Fly Tuning

- Stacked Planar Inverted-L Antenna with Enhanced Capacitance for Compact Tag Design

- Investigation the influence of miniaturized RFID tag sensor on coupling effect

- Slim RFID Tag Antenna for Metallic Tools With Narrow Footprint

- Miniature Folded Dipole in Rotational Symmetry for Metal Tag Design.

Machine learning and Blockchain

Machine learning and Blockchain combined with RFID are rising research areas.

- Making Assembly Line in Supply Chain Robust and Secure Using UHF RFID and Blockchain introduces a Blockchain-based secure supply chain for bottled consumer products.

- This paper introduces how changes in RSSI of an RFID tag can be detected, and how a reading system can be taught to identify contaminated food using the changes in RSSI. Machine Learning Enabled Food Contamination Detection Using RFID and Internet of Things System

Voyantic Tagformance

Voyantic Tagformance® system is widely used in RFID and NFC research. Read more or book a demo to learn more.

All blog posts