It was my third time to attend the GS1 Connect event; this time in Washington, DC from May 31st through June 3rd. The event was loaded with an impressive conference menu and a larger exhibition area than in the Austin event last year, although with less exhibiting companies than previously. RFID was well presented – read on to see what I am taking home from that perspective.

Utopia Comes with Transparency and Traceability that Protects Both Business and Consumers

Standardsville is a picturesque city where everything is clean, convenient, traceable and safe. Business blooms because information and goods flow without obstacles, and The Consumer is protected from harm. Actually I thought GS1 had done a really nice job on creating this Standardsville utopia as the theme of the event.

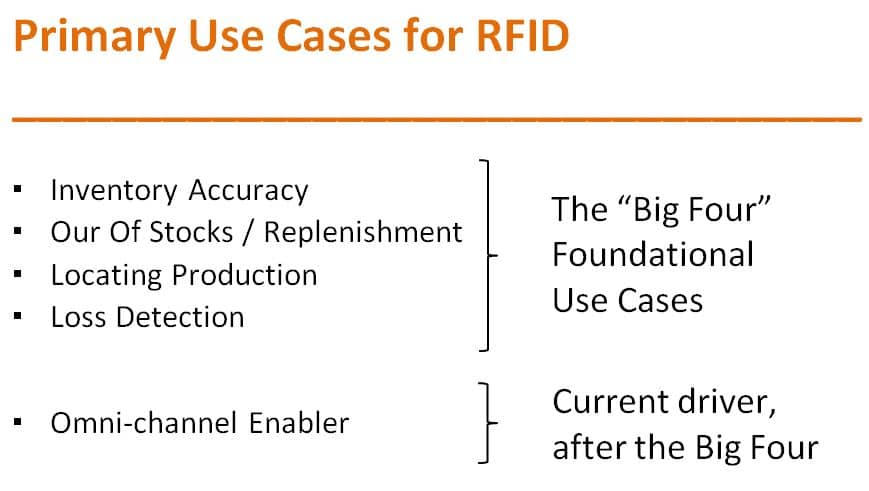

In his keynote speech Mr. Bob Carpenter, the President and CEO of GS1 US, highlighted RFID as one of the transformational technologies that is currently reshaping retail. In a conference session the same message came through the presentation of Dr. Bill Hardgrave of Auburn University. Dr. Hardgrave listed the “Big Four” Foundational Use Cases of RFID together with the additional current driver: the omni-channel retail.

For the most effective RFID execution Dr. Hardgrave again gave the ultimate guidance: “Move to 0HIO“.

RFID Is a Strategic Enabler for Macy’s

In the Macy’s HTDBW session Mr. Bill Connell, Senior VP of Logistics at Macy’s, explained the reasons why Macy’s is so committed to RFID – sales uplift is naturally the ultimate reward, but all the other benefits of accurate inventory also add enormous efficiencies to store operations. The consumer sees all this as improved shopping experience, whether she is online or in-store.

Supplier Source Tagging Is Happening Already

Mr. Connell also made it clear that supplier source tagging is the only way to do this right so that benefits are spread thorough the supply chain. Today tagging coverage among Macy’s suppliers is 56%, and Mr. Connell expressed his wish that the rest would start tagging tomorrow.

In a separate session Rich Haig, the CIO of Herman Kay, one of Macy’s suppliers, presented their experiences around RFID. The added visibility that RFID has brought to their own processes has dramatically affected shipping routines and raised accuracy to a whole new level. All this has made Herman Kay a better supplier for all their customers.

Many Retailers Put Emphasis on Product Attributes and Rich Content

As omni-channel retail marches forward, it seems that most retailers have their focus on getting the content right on their webstores. As an example, Walmart is focused on getting every single item online, including those that they are not currently even selling! As an engineer I am struggling to follow this logic, but I suppose that’s just me.

I understand rich content and romancing the product is essential to fight the online competition. However, behind the curtains many are following what the spearhead retailers are doing around RFID. For the latecomers implementing RFID is going to be a smoother ride because supplier source tagging is already happening, standards are emerging to make communication easier between stakeholders, and successful tagging solutions have become a common knowledge in many product categories.

TIPP Is Like the Air We Breathe

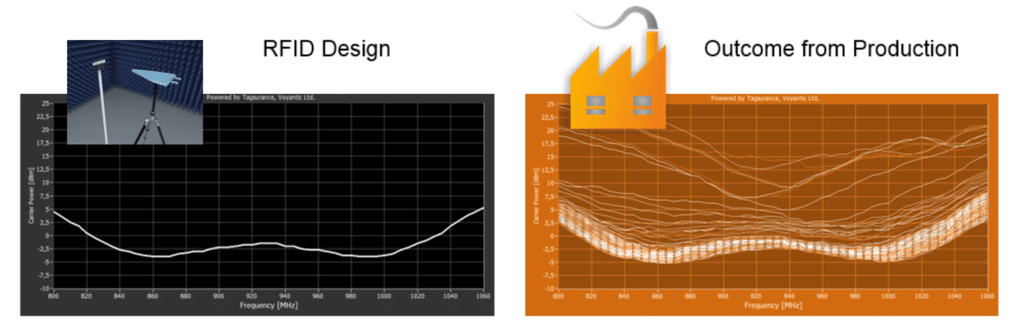

So, why are the retailers not implementing the Tagged Item Performance Protocol (TIPP) that was just recently developed for them? I’ve learned this actually is just an illusion. The way professional RFID tagging in retail is done today is solely based in TIPP-like methodology – some just call them ARC tests and others Voyantic tests. Common factors include tags applied on products/materials, organized to in-store like product stacks and then tested over a wide frequency band and across rotation angles.

TIPP grades will take their place as a communications method as tagging spreads to new product categories and new retailers. This is already happening, and I am sure the TIPP methodology will be discussed more at the GS1 Connect 2017.

GS1 Connect 2017 Taking Place in Las Vegas

As business moves forward the next GS1 Connect will be held in Las Vegas. Unfortunately the event is moved forward by a couple of weeks to 19th-22nd June, which will be right on top of the Finnish Midsummer’s Eve – the magical nightless night. Considering the night in Las Vegas may well be somewhat similar, I will be faced with a difficult decision between bonfires and casinos.