On Feb 17th 2021, we hosted an online panel discussion on the future direction of RAIN RFID tag design and tagging implementations. The panelists for the discussion were Matti Tavilampi from Avery Dennison, Steve Berry from Impinj, and Jesse Tuominen from Voyantic.

In case you missed the discussion, view the recording HERE

The discussion topics ranged from industry trends and standards to the development of readers, systems, ICs, and manufacturing technologies as well as embedded tags and smart packaging.

If spending an hour on the webinar recording does not currently fit your schedule, we made a quick recap on the topics and main points that came up during the webinar:

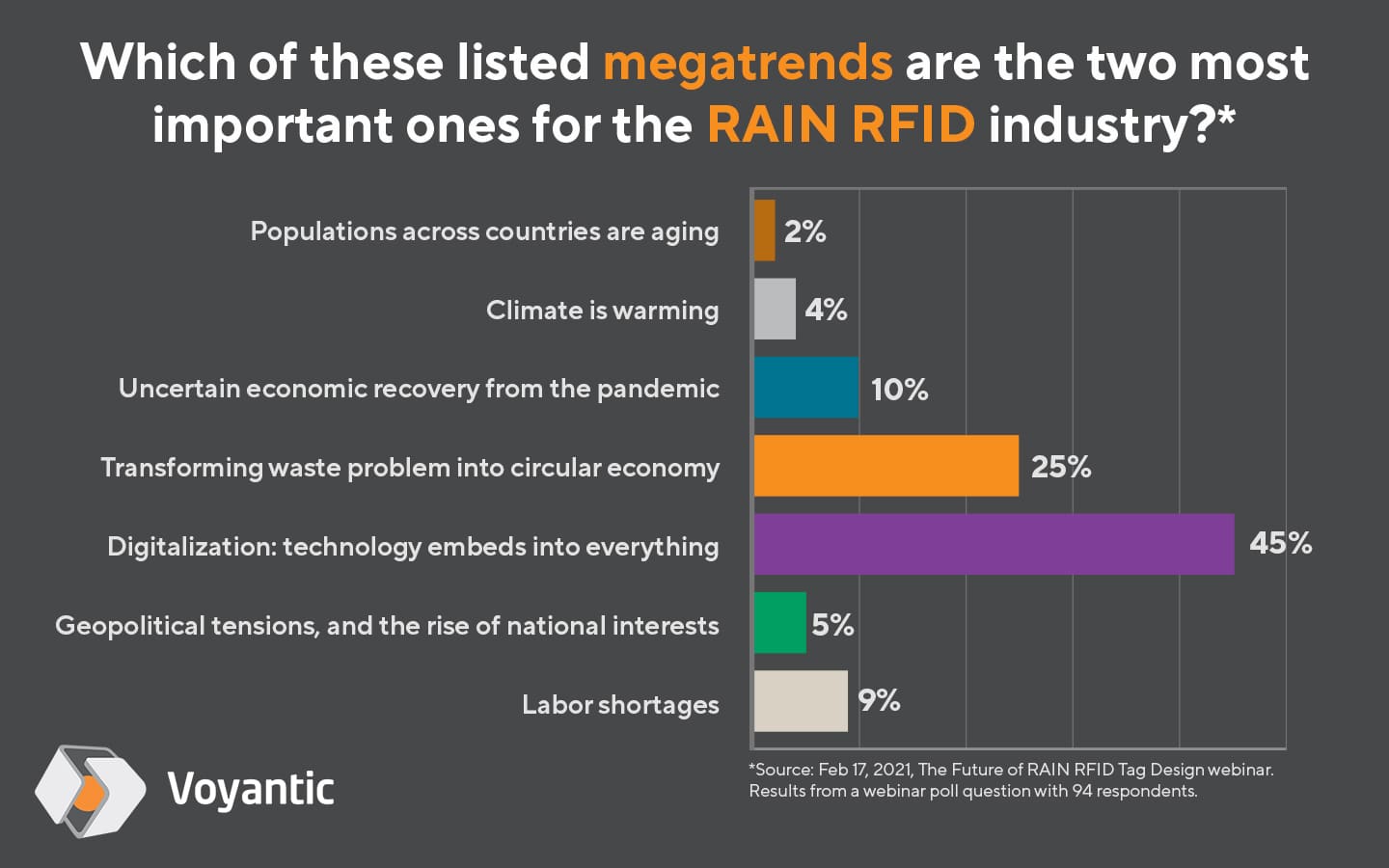

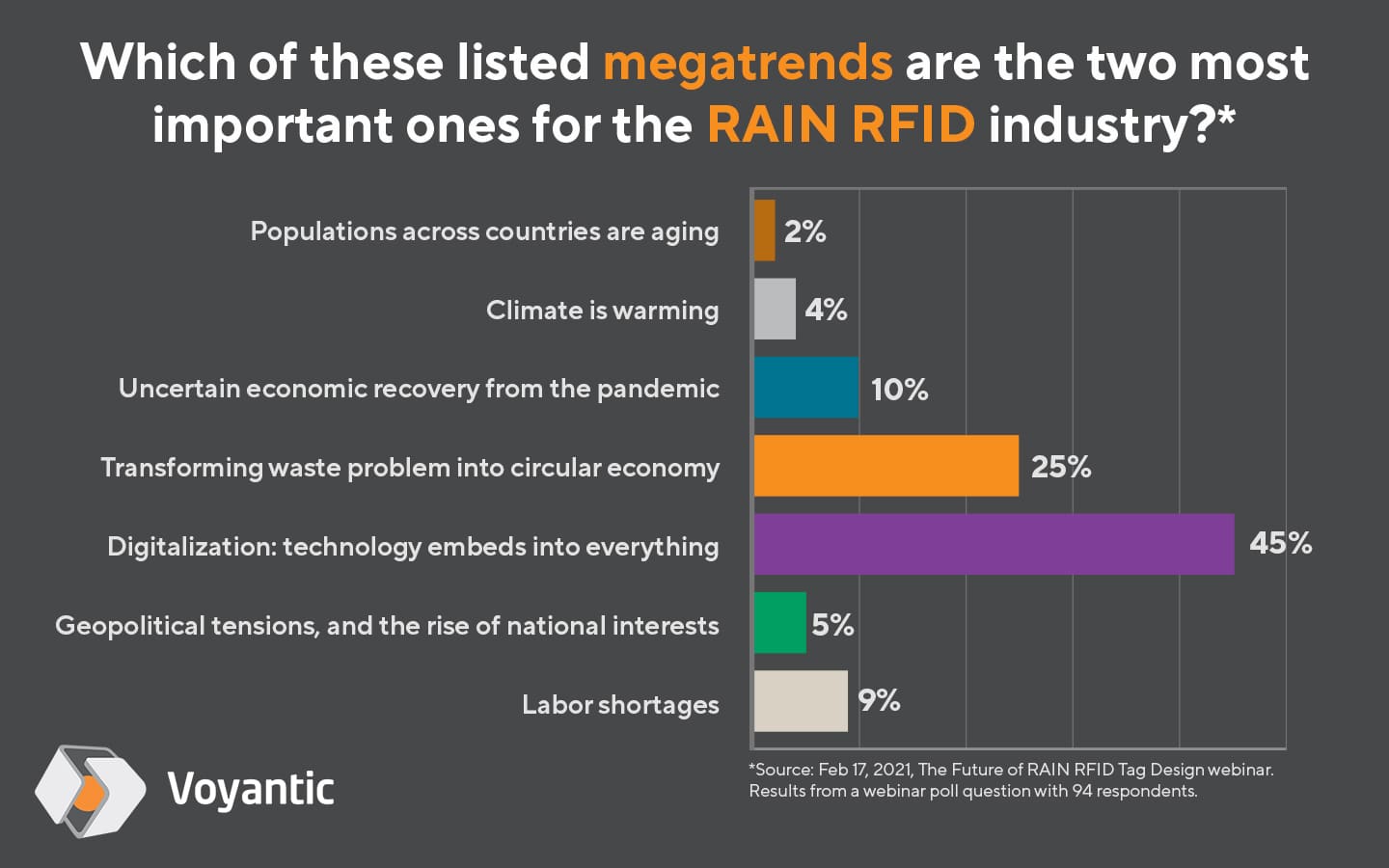

Early on to the panel discussion, we asked the numerous attendees to weigh in with their preferred two megatrends that strongly affect the RAIN industry.

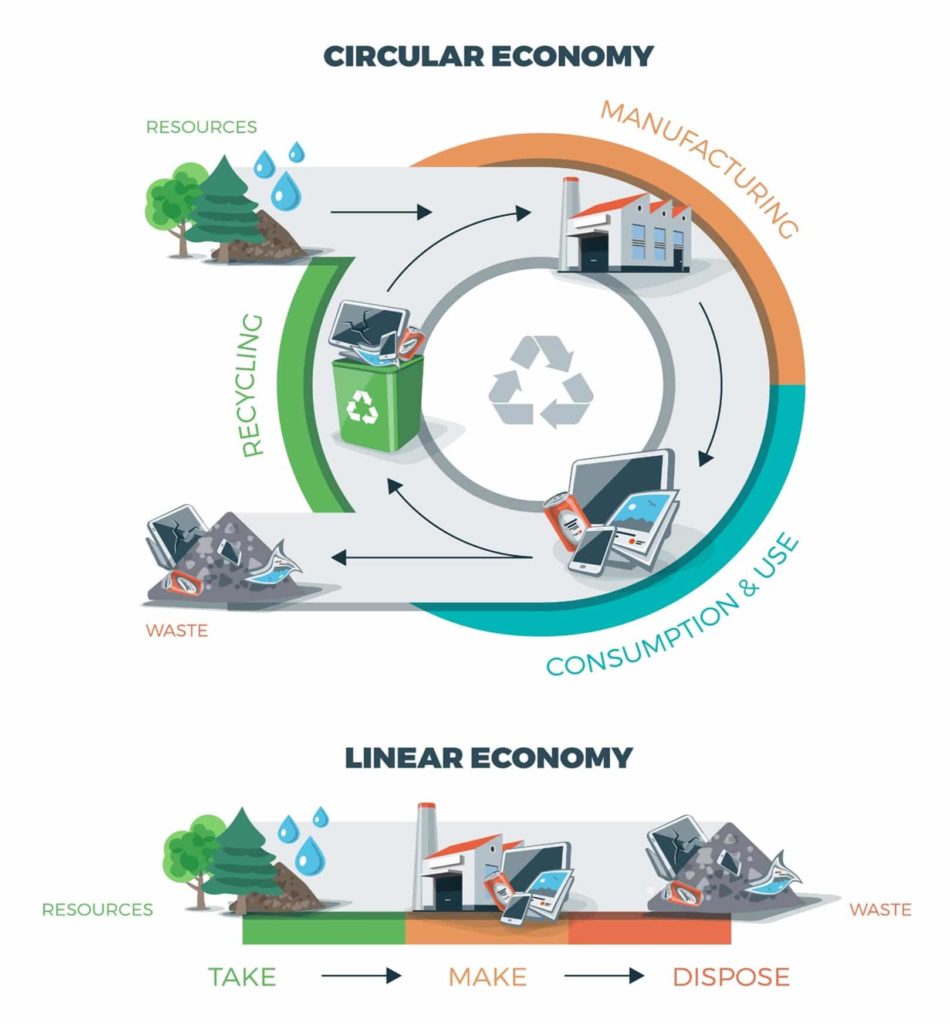

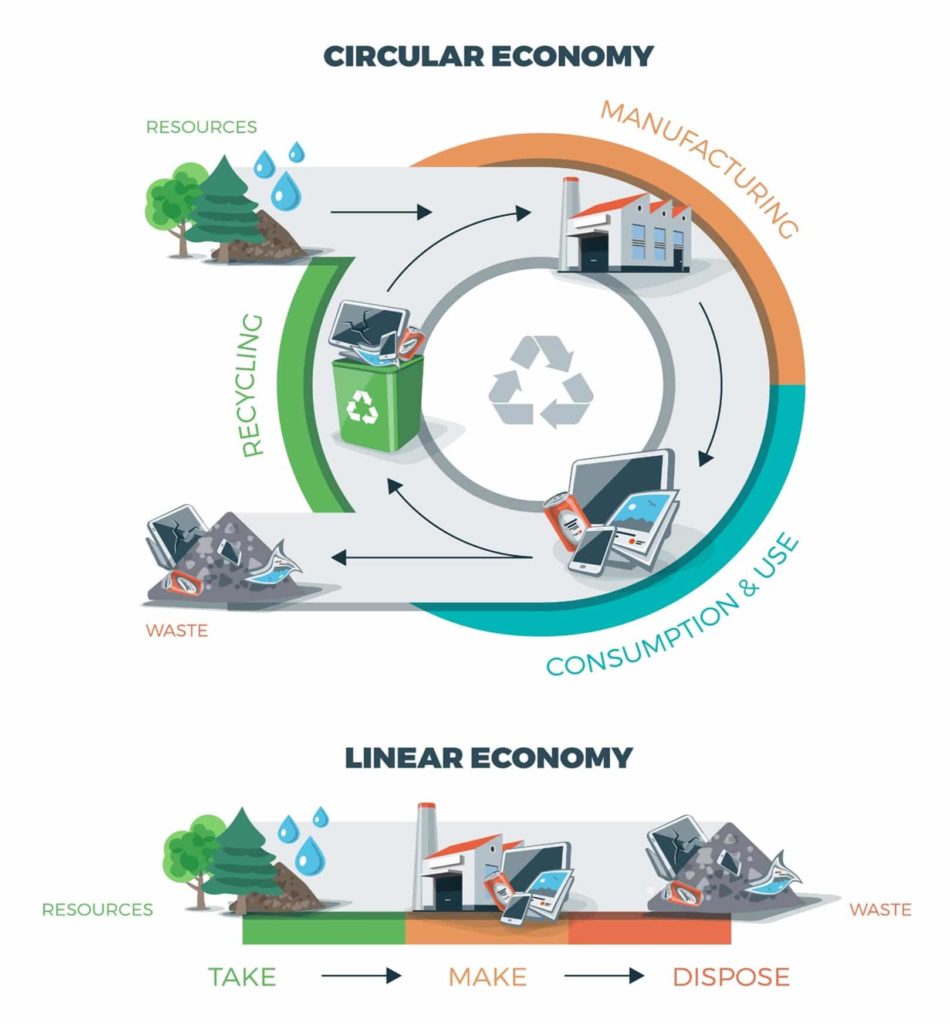

RAIN RFID and circular economy

At first, RAIN RFID tag volumes started to grow in retail applications 10 to 15 years ago. Now the same tags are increasingly being used in manufacturing and the supply chain before the retail stores. The expectation is that the same tags will also be increasingly used in applications beyond the point of sale.

Tags are being applied more and more in item manufacturing. Source tagging poses new requirements for the RAIN RFID tagging. Tagging should support both the FCC and ETSI regions, and perform well in dense populations. Endurance and ruggedness requirements increase, because, for example, tags on garments must survive the entire life cycle of the item. Data privacy must also be considered differently when there are multiple users for the tags.

Dual-frequency tags are one approach. In some applications, a tag can combine supply chain tracking (RAIN) and consumer interaction (NFC).

Standards

The core of the Gen2 air interface has been stable for a relatively long time. The adoption of RAIN RFID technology has benefitted from the stable standard environment.

In the IC market, there seems to be a split between:

- bare functionalities,

- and more complex features in the protocol, such as authentication.

When it comes to protecting tag data from rogue readers, there are some users already for encryption and authentication, and interest in these possibilities seems to be increasing.

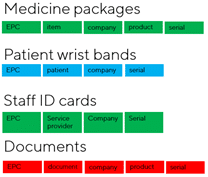

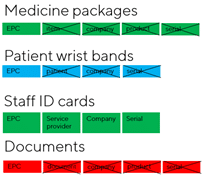

A viable policy is to pay only for the capabilities and features that are essentially required by the use case. Designers should know the air protocol standard at some level, and then industry-specific standards relevant to their target segment (aerospace, tire RFID).

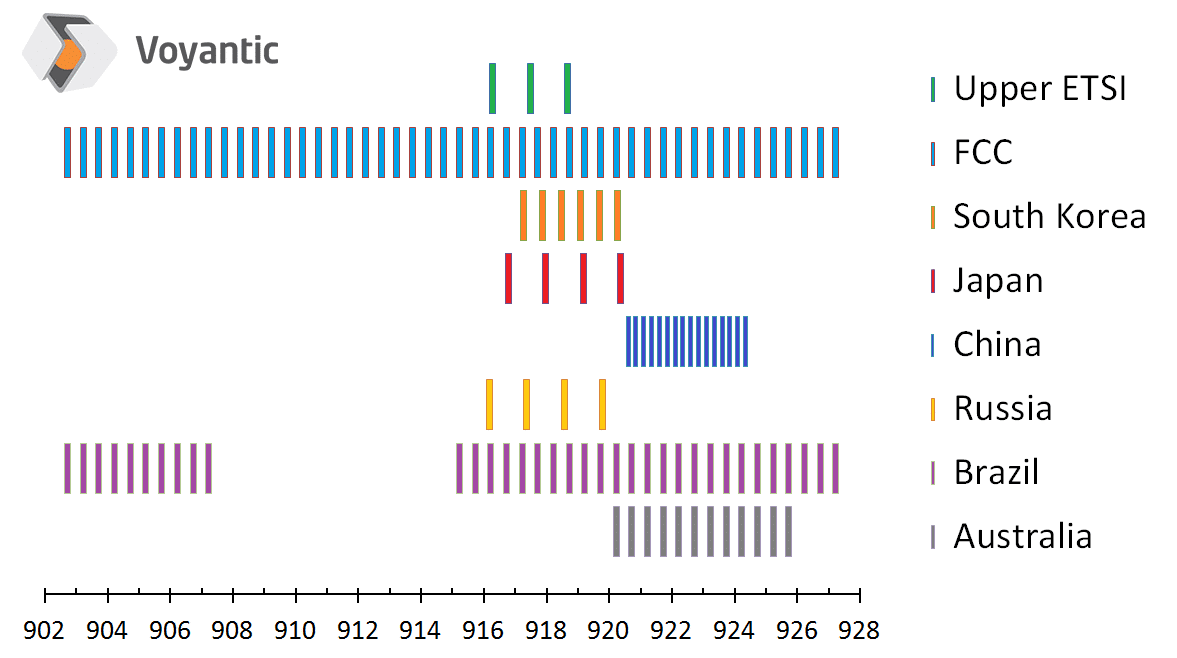

Frequency allocation is something that designers should be aware of – especially the status of the upper ETSI band. Ultimately the upper ETSI makes tagging easier and brings new optimization possibilities. Optimization for upper ETSI comes naturally because other geographical areas are in the same frequency area.

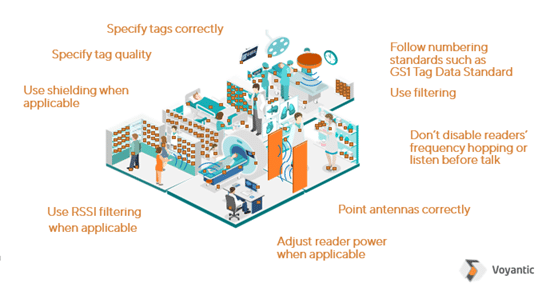

Readers and systems

During the discussion, it was noted that the human operator is often the weak link in handheld scanning. Transition to overhead readers is ongoing, although an even faster transition was expected. In addition to overheads, also EAS gate and other fixed reader types’ use is increasing. The main hurdle to applying a new type of readers is twofold: the slowness in changing processes and business practices, and secondly, the longer read distance increasing tagging performance requirements.

Applications will also focus more on movements and transitions, not only on counting. These new types of applications are based on advanced algorithms tightly connected to the readers. Impinj for example has focused on improving sensitivity in the latest reader designs. It is a constant race, and more often reader sensitivity is the bottleneck.

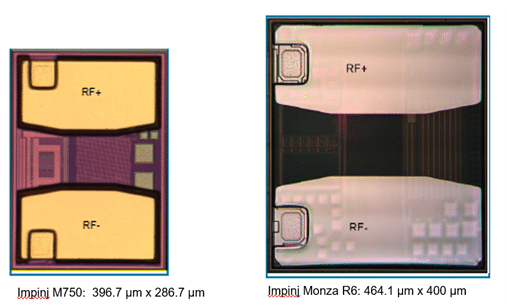

IC sensitivities have improved roughly 15 dB in past 15 years. Operating ranges have increased six-fold from the first designs. ICs are also shrinking in footprint; Monza 1 was about 10 times the size of the latest Monza version. At the same time performance has increased. With smaller sizes also the IC cost has decreased.

The technology has matured. Modern ICs are stable. Memory corruption, clock shifts, etc issues are not seen anymore. On the other hand, there are plenty of specialty ICs with kilobytes of memory, data busses, logging, etc.

Sensor ICs were also discussed. Passive technology of RAIN RFID is easy in many sensor applications. The challenge is operation when there is no active reading around, for example, in data logging applications. RAIN RFID does not fit everywhere, but more sensors will be seen, for example, in cold chain applications.

Up until today, it has been evident that high manufacturing volumes require big machines. This is true especially for labels, both for manufacturing inlays and in converting the inlays to labels.

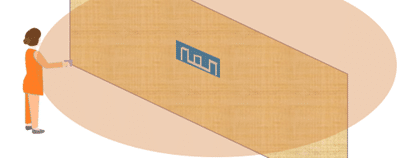

Distributed manufacturing will be seen more in personalizing the tags. Embedded tags will change manufacturing, and this change has started and will continue. Instead of one label process, the process is divided and integrated into different item-specific manufacturing processes.

Embedded tags are already in use in a variety of applications. Apparel care labels are already made in volumes. Also, tire tag volumes are increasing.

In many industrial areas and healthcare, further standardization is probably needed before embedded tag volumes grow. For example, the tire industry already has an ISO standard in place for tagging, enabling the industry to implement RAIN in a way that is both scalable and interoperable.

Embedding tags is happening right now, for example, with consumer packaged goods. Food tags are being integrated more and more into the packages, instead of a label on top of the package.

New antenna types and materials

Aluminum will not go away in the near term. There are plenty of established machines and production processes. Aluminum also has its benefits. Recycling the tags in paper packages is a frequent question. The current recycling processes handle this automatically. Separating metal from paper and plastic is already done efficiently in recycling.

Manufacturing will develop and change, processes are becoming more environmentally friendly, using fewer chemicals and creating less waste. New materials will first come to use, for example, in food packaging, where metals need to be avoided.

The above points are a brief summary of the discussion. The full recording is available here ›

All blog posts

On the positive gains, the

On the positive gains, the