4id Solutions Relies on Voyantic Tagsurance 3 to Ensure the Highest Product Quality

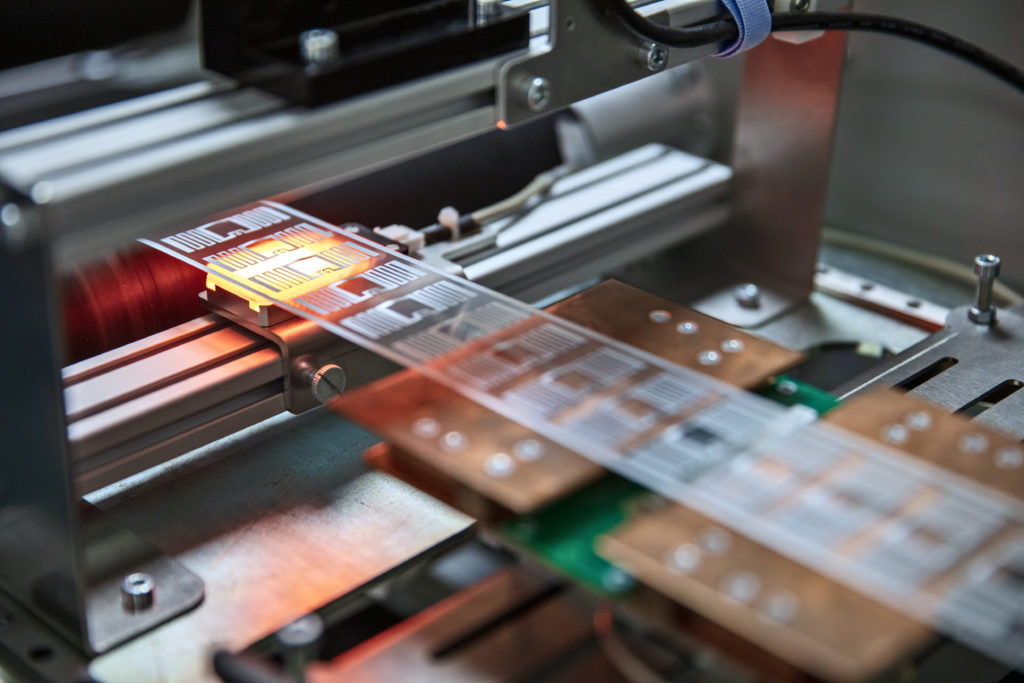

4id Solutions specializes in the innovative manufacture of smart labels and tags using RFID and other contactless technologies.

As an established RFID converter with a proven global reputation for delivering high-quality RFID products, 4id continues to set the standards for what customers should expect from their converter.

Through an array of proprietary solutions and unparalleled production efficiencies, 4id presents innovations that transcend the realm of current industry thinking.

Dedication to Quality

4id is dedicated to the highest requirements for quality and reliable products where the performance meets or exceeds the requirements of their customers. The Voyantic Tagsurance 3 inline Quality Control System gives a full picture of the performance of the converted labels. By understanding the detuning effect of the RFID label converting process, 4id can work with inlay manufacturers on antenna design and target frequency tuning. The system also affords the ability to undertake extremely low-level testing to detect potential reliability issues.

Tagsurance 3 Systems Measure the Label Performance on the Production Lines

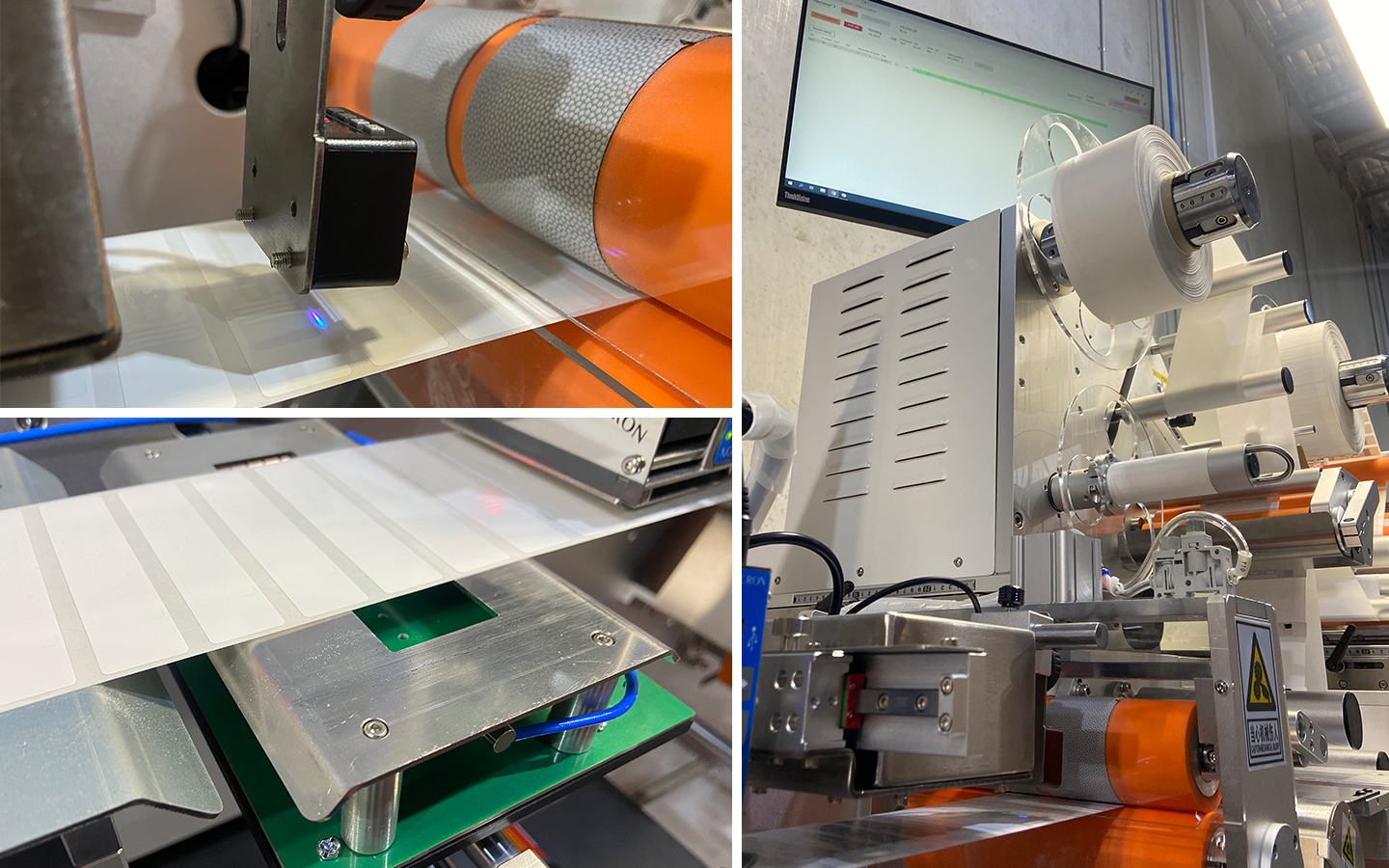

4id currently has several of the Tagsurance 3 systems deployed on their converting equipment in both single and multi-lane configurations. With a limited number of product offerings in this space, 4id Solutions undertook a thorough review of the systems available and Tagsurance was determined to be the best solution when assessed against their requirements.

Knowing Voyantic is the system used by several inlay manufacturers also provides confidence in the solution offered while allowing 4id to conduct like-for-like testing of inlays to ensure the results achieved through our testing align with the results and data provided by the inlay manufacturers.

The Benefits of Tagsurance 3

The insights provided by Voyantic’s system during the RFID verification process have contributed to 4id’s product development strategies. Understanding the performance characteristics of RFID tags has allowed them to make informed decisions regarding tag selection and integration into new products.

The increased efficiency in RFID testing has contributed to shorter product development cycles. This acceleration is attributed to the expedited data capture and analysis facilitated by the Tagsurance system.

“The product delivered by Voyantic has exceeded our expectations in every way. Its functionality, user interface, and performance have truly transformed the way we operate, making our processes more efficient and streamlined. The attention to detail and innovative features demonstrates the commitment Voyantic has to delivering top-notch solutions,” said Wayne Oldham, Innovation and Sustainable Technology Director at 4id Solutions.

“The training provided by the Voyantic team was thorough. Their knowledgeable trainer ensured that our team not only understood the ins and outs of the product but also felt confident in implementing it into our daily operations. The training sessions were not just informative but also engaging, making the learning process enjoyable,” Wayne said and continues: “What truly sets Voyantic apart is their unparalleled level of support. Whenever we faced challenges or had questions, their support team was quick to respond and went above and beyond to resolve any issues. The dedication to customer satisfaction was evident throughout our interactions, and it is clear that Voyantic values their customers’ success.”

Planning for the Future

While still relatively early in their journey with Voyantic, 4id has already ordered and deployed Voyantic systems beyond their initial order. “As 4id is a company that prides itself on a continuous improvement cycle, as we adapt and improve our equipment and processes, I have no doubt this continued success will lead to further additional deployments of not only Tagsurance, but other products within the Voyantic portfolio,” Wayne reveals.

What do the 4id Solutions Team Members think of Tagsurance 3?

Shannon “Billy” Clarke, Machine Technician – “Tagsurance provides guaranteed assurance of the quality and performance of the inlay against other readers. It offers a lot more peace of mind with higher speed and more reliability”.

Jack Hallett, Trainee Machine Technician – “The UI is easier to use and navigate. It is easily adjustable and good for beginners. It is easy to manage and has less need for management. It assures quality and I can always rely on the Voyantic system”.

Conway Harvey, Machine Operator – “The implementation of the system and the possibilities it offers greatly helps with quality control and accuracy as key functions”.

“The product delivered by Voyantic has exceeded our expectations in every way. Its functionality, user interface, and performance have truly transformed the way we operate, making our processes more efficient and streamlined.”

Wayne Oldham, Innovation and Sustainable Technology Director at 4id Solutions