I work as the CEO of Voyantic, a company that specializes in RFID test and measurement equipment. Since our systems are used by hundreds of companies around the world, we often come across cases where a customer needs our help to verify that their tags work as they should. This is a story about a case where things went wrong.

Tagging Athletes in Cross-country Skiing

We got involved with a very interesting case a couple of years ago. A small RFID integrator that we have known for some time wanted to tag athletes in a cross-country skiing competition. The idea was to use RFID for timing the race. And you can guess that if someone spends several hours on the ski track, being left without a race time is definitely not an option.

There are many different ways to tag athletes in timing solutions. Common approaches in running competitions include integrating the RFID tags to the race bibs or attaching them to the shoes of the runners. However, in this case, the chosen approach was to buy wrist-band tags and to attach them to the ankles of the skiers. The tags were read by fixed readers that were set up on the side of the tracks.

The integrator went through the specifications of several different wrist-band tags and finally contacted a fairly well known maker of specialty tags for some samples. The samples arrived the following week, and the integrator ran some field tests. Everything worked well. He was able to detect every skier that passed the reader antenna.

So the integrator decided to order the tags that he needed for his application. Once again, there was a timely delivery of correct amount of tags. However, when he started to build the application, he noticed that not all of the tags were working. A typical discussion between an unsatisfied customer and a worried supplier followed.

The conclusion was that all the supplied tags worked according to the specification.

The tag manufacturer tested both working and non-working tags attached to the wrist of whoever they considered to be their standard-human. All tags were readable from a distance of 2 m which was the specification. But they didn’t all work in the end application. How is this possible?

Analysis

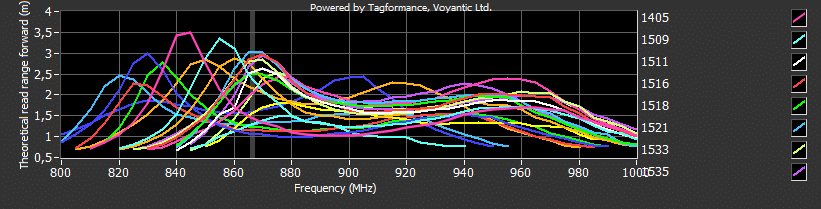

We got involved with the case at this point. We were asked to take a look at the tag samples to try to understand what was going on. So we ran a performance test for the tags using the Tagformance measurement system. The results from the Threshold Sweep measurement are shown below.

We tested the tags in free air, so they were not attached to a wrist or an ankle. But even in this setup it is clearly visible that there are significant variations in the tuning and performance of the tags. So this is what we think happened:

- The integrator decided to use the tags differently from what the manufacturer had specified

- The first samples sent by the tag manufacturer performed clearly above the spec

- The integrator concluded that this tag will work in the application

- The next tag batch – even though still within the original spec – performed differently

- A part of the tags didn’t work.

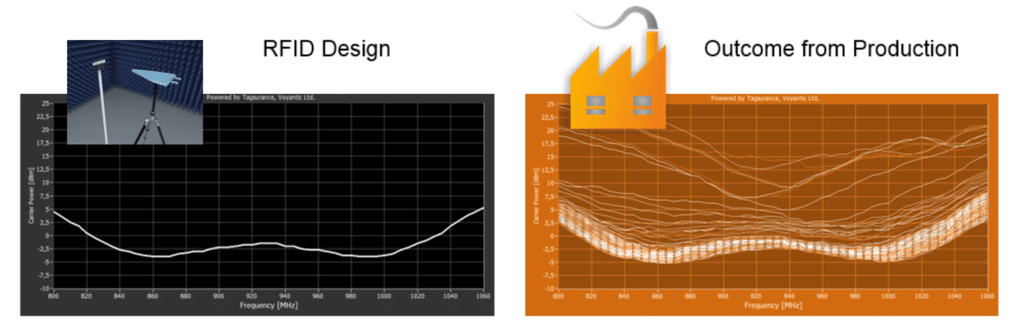

So, it is very hard to point fingers in this case. But there is something that the RFID industry needs to improve in. The industry is already doing a decent job in reporting the performance of their tags, e.g. in expected read range. But I think there is a lot to improve in how performance variations are reported, because that is a key factor in building reliable RFID systems.

And what happened with the skiing competition? Did the integrator get the system to work? He did. But he had to manually test through the tags and hand-pick the ones that worked well enough. Hardly a perfect outcome but every skier got their time.

My company Voyantic specializes in test and measurement solutions for the RFID industry. Are you interested to learn more about RFID quality control? Download our sample quality test report and contact us.

White Paper: How to Minimize Quality Variation in RAIN RFID and NFC Smart Label Manufacturing

Learn the practical effects of quality variation and how to minimize it.