The majority of the UHF inlay designers have already come to realize that the right measurement solutions are the critical factor for seeing all you need on the UHF inlay performance. There’s not much of those guys anymore, who run around with the tags, checking with a reader how far you can go until the tag can’t be read anymore. Not only is this kind of measurement inaccurate, but it also doesn’t give any indication of what kind of changes are necessary for the next iteration in the design.

In my work as a Product Manager at Voyantic, I have seen the accurate, communication based, wide frequency band measurements for the UHF tags become more or less the de-facto standard of the industry in tag design. Now I’m happy to see the tag manufacturers widely adopting the performance testing also in production quality assurance.

So from design to production – why should you measure tag performance?

Quality from Design to Production

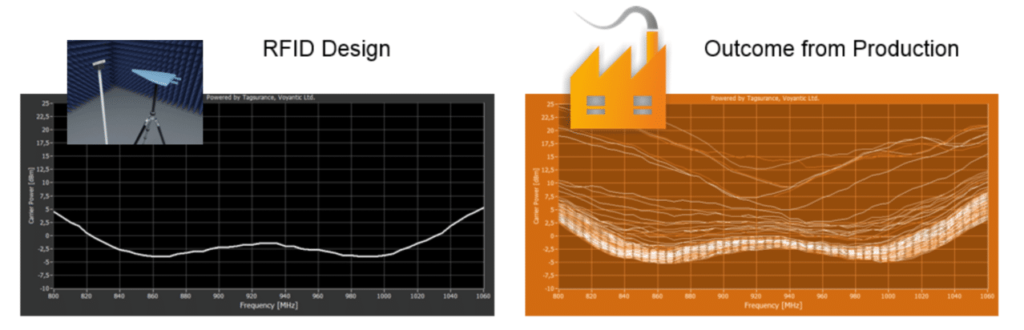

The measurement solution giving visibility to the UHF tag performance throughout its wide operation frequency range helps the designer to see exactly how the tag performs and understand what modifications are required to improve it. This enables faster development cycle times by providing high-performance UHF tag designs with shorter time to market.

This same yields to the production quality as well. Let’s take an example of a new product introduction, where an inlay design is brought to the production floor for the first time. If the RFID test equipment in the manufacturing machines can only tell whether the tag is functional or not, the batch will typically be taken to a very comprehensive and time-consuming first article inspection in the lab.

Imagine the reduced downtime!

If the samples are analyzed in the lab, not only does it take much time, but also the corrective actions can be implemented after this detailed analysis step. Imagine making a similar analysis on the production floor during the first batch manufacturing. Making the fine-tuning of the process on the go and reducing the time to market and machine downtime. In addition to the high-speed process compatible performance testing, the Tagsurance UHF testing equipment can also handle this more detailed analysis job.

Performance testing reduces the overall cost of quality without creating a bottleneck to the process.

Regardless of the process, there are always benefits in the performance testing of the tags. In the chip assembly, it is clear, the performance of the tag is created in this process when the chip is attached to the dipole antenna structure. In label converting, the main thing is to verify that this performance is maintained, but a reader can only check the tag still functions. The functional testing does not allow visibility in what is going wrong when the failures start occurring, and it can’t detect all the abnormalities and poorly performing tags, which then end up in the application use.

With the right tools, I’ve seen young startups reaching the same quality level with their UHF tag products as the big players of the market in no time. Without having to go through years of learning, in the worst-case learning from the failures noticed not until in the end customer application. This is the critical thing when balancing your overall cost of quality; investing in quality appraisal and failure prevention will spare your investment many times in the failure costs.

Let’s Take the RFID Industry to the Right Direction

Together! I have had the pleasure of working with so many quality-conscious RFID experts in the past years and have enjoyed seeing how much improvement you can make with the right tools in a short time. The increase of interest in production quality and implementations of Tagsurance UHF RFID testing solutions during the past year has made me gain confidence in the UHF RFID. It will no doubt be the technology to enable reliable, repeatedly functioning applications, without component level surprises in the application piloting stage.

Thank you for your interest! If you have any questions or want to start a discussion on how you could improve your RFID quality, let’s talk more! If you want to learn more detailed on what type of test data you could achieve in production, download the full sample roll test report below.

Learn Exactly What We Can Find Out on a Roll of UHF Tags!

Download a full Voyantic sample roll test report with full visibility to the performance of each and every tag on the roll, far field measurement results on selected tags and optimized production test scenarios for different process throughputs.