4id Solutions – Experiences with Tagsurance® 3 encoding

In Spring 2025, Voyantic announced the launch of the new version of the Tagsurance 3 quality testing system, including a RAIN encoding feature. In the final stages of product development, we involved some of our long-term partners to test the encoding functionality and provide feedback. One of those partners was 4id Solutions, known for its innovative smart labels and tags built with RAIN RFID and other contactless tech.

We sat down with Wayne Oldham, Director of Innovation and Sustainable Technology at 4id Solutions, to hear firsthand about their experience with Tagsurance 3 encoding.

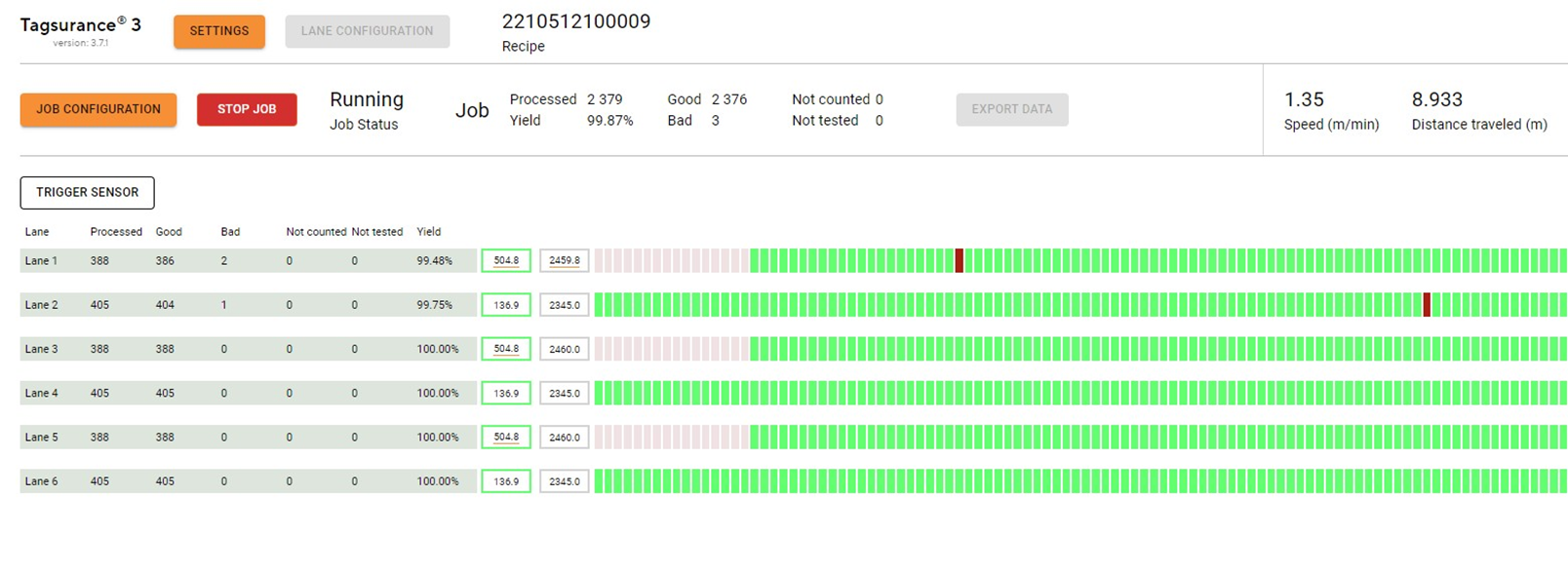

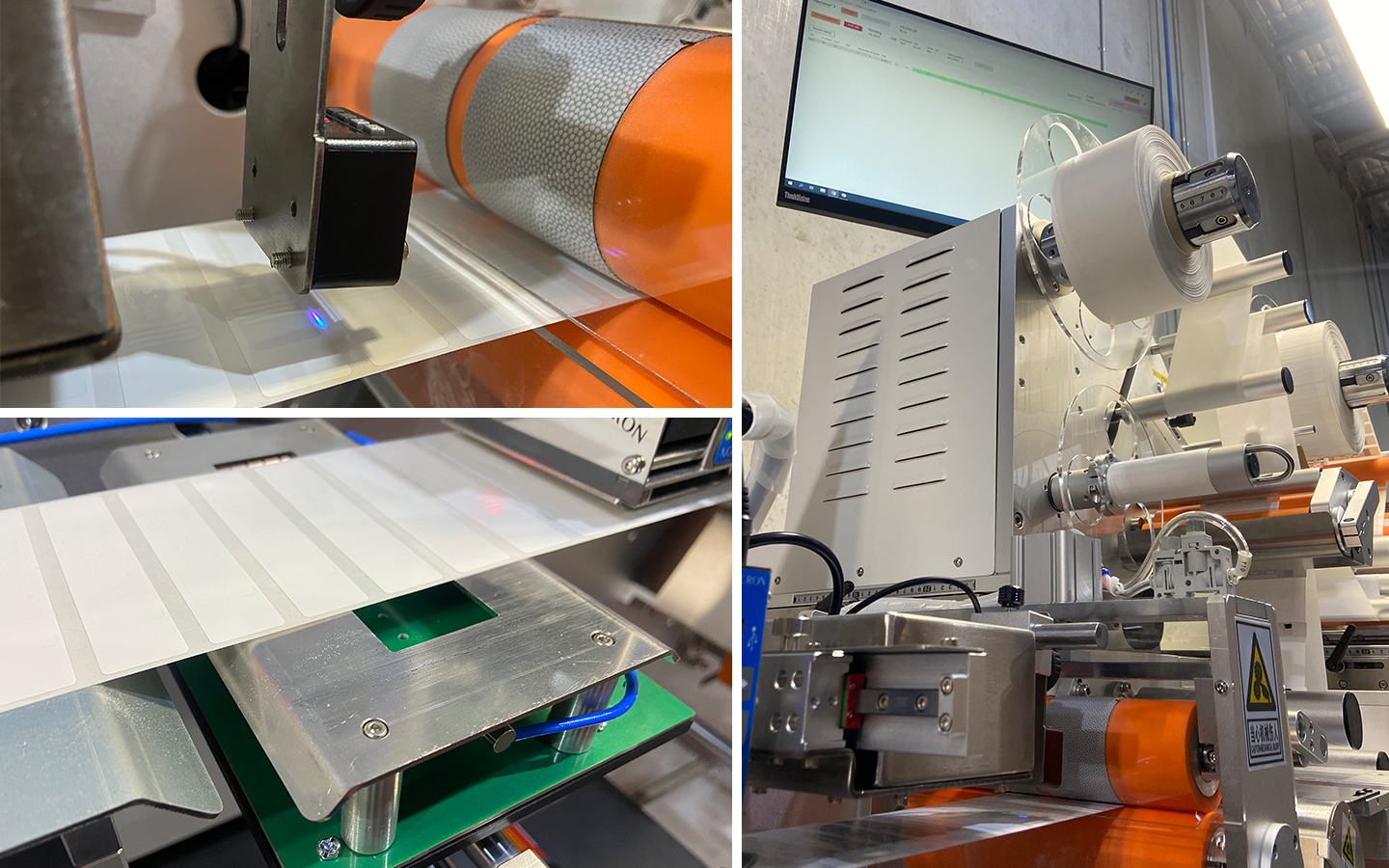

“At 4id, we have been using the Tagsurance 3 platform as our primary system for the performance testing of all our UHF product offerings, comprising inline on press inspection as well and pre- and post-conversion performance testing”, Oldham summarises the history with Voyantic Tagsurance system.

“Due to the strong partnership which has been fostered between 4id and the team at Voyantic, we are privileged to have been involved in the beta testing of the Tagsurance 3 version 4 encoding system. The high volume of converting and encoding we undertake has allowed us to provide real and valuable production-based feedback across a range of low and high-speed converting equipment, reflecting both static and variable data”, Oldham reflects.

Speed and Ease of Use Beyond Expectations

While our partner anticipated some clunkiness and unexpected errors during testing of the newly implemented feature, the experience turned out to be remarkably smooth.

“From the initial unboxing to power up and running the first configuration tests was less than 30 minutes. Our expectation was that it was going to be a separate process to test and encode, with the encoding being a much slower process, however the updated version has allowed us to undertake both functions while running at speeds higher than we would normally run in a production environment”, Oldham reflects impressed.

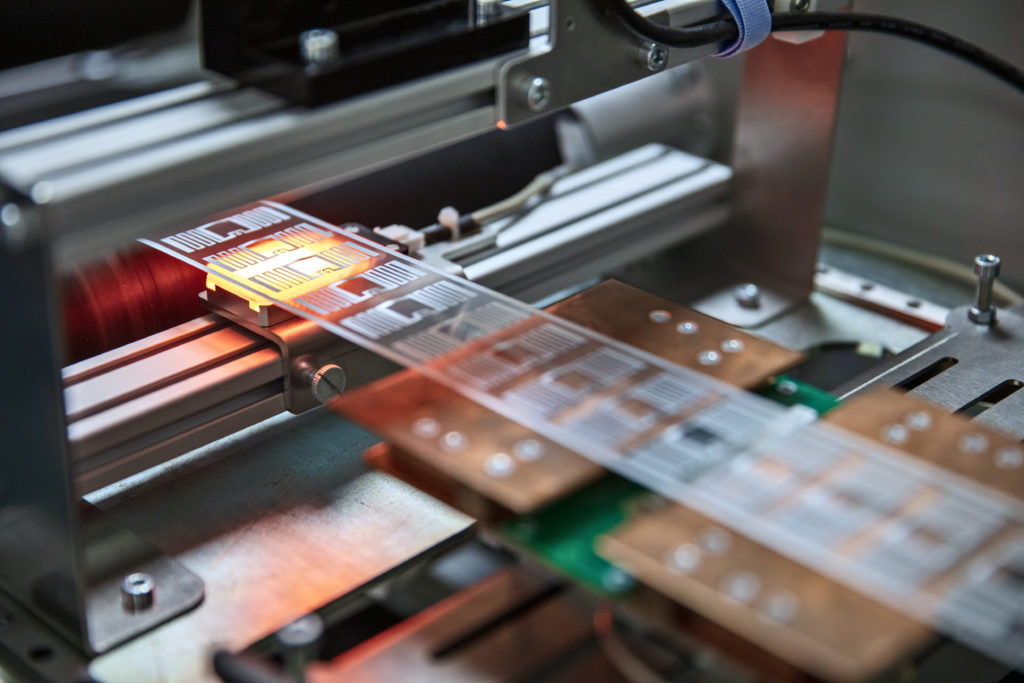

The tests 4id Solutions undertook with the Tagsurance 3 encoding system included static and variable data encoding on various inlay sizes and pitches, along with a range of different IC’s.

“Obviously, there are a range of factors which affect the speed at which Tagsurance can perform, such as the IC generation, inlay design, pitch of the product, however we were reliably able to encode 60,000 units per hour with 100% accuracy which more than services our requirements and has exceeded expectations”, Oldham summarizes the results.

“Despite being robust, our previous UHF platforms have not been able to perform at the speeds we have been able to achieve with the Tagsurance system.”

The system has also proven to be reliable. “As we have moved along with the testing journey, the system has demonstrated its reliability well beyond what expected. We were made fully aware of where each aspect of the development was at, so we knew what we could really push, and those items which were still being refined”, Oldham recalls.

Improved Operator Efficiency

With the latest version of the Tagsurance 3 system (4.x), Voyantic introduced a new cloud-based architecture. One of the most notable updates that came with it is the new browser-based user interface, which both administrators and operators can access from any computer.

“The ability to be able to run the platform as a remote server rather than require a separate full keyboard, video, mouse has been a massive improvement from a real estate and operator efficiency perspective. Operators are now able to view and control multiple aspects of the converting system from a single point.”, Oldham points out.

“In addition to the hardware improvements, the other significant benefit of the server model is the ability to easily upload the encoding files and download the encoded output files for verification and integrity checking. With no hardware changes required between performance testing and encoding, this has allowed for an increase in machine uptimes due to more rapid job setup and changeover. The system now also allows testing and encoding to occur simultaneously allowing the use of one system for quality testing and encoding, eliminating the need for separate systems.”

The person behind the insights:

“I am Wayne Oldham, and I have been working in the RFID space for a little over 5 years now. My primary role within 4id is innovation and staying abreast of sustainable technologies. A considerable part of the innovation work is around determining the most suitable technology adoption to both address market requirements and develop new functionalities.”

What kind of use is Tagsurance 3 encoding the best fit for?

“Anyone looking to perform encoding static or file-based data at volume would benefit from the new system. It performs well at high speed with high reliability.”

Would you recommend this feature to other users?

“Absolutely! The wait has been more than worth it for what the system offers.”

How do you see the future of your collaboration with Voyantic?

“4id looks forward to continuing working collaboratively with the team at Voyantic on not just encoding or the Tagsurance platform, but other products within their portfolio as well on both a hardware and software level.”