What does EU tax harmonization, the war in Ukraine, and TIPP adoption have in common? All three appear to be stagnant battlefronts with plenty of hard work done behind the scenes but minor visible progress to outsiders. Is there something wrong with the world order, how to move forward? Relax, take a sip of Dr. Pepper and read on to see why and how TIPP will prevail.

What Do TIPP, Tire Sidewall Codes, and Automotive Oil Grades Have in Common?

TIPP is an acronym for Tagged Item Performance Protocol. The TIPP methodology was initially created in the USA to simplify and standardize the communication and accountability around RFID tagging. RFID tagging of retail items dramatically improves inventory accuracy. Without RFID, it is impossible to sustain accurate inventory, especially on the shop floor level, and without accurate inventory a retailer cannot effectively execute their omnichannel sales strategies.

With this said, TIPP is a significant leap forward for any RFID adopting industry that looks to cut tagging costs, simplify communications, and clarify accountability. This approach would equally well serve the RFID adopters in the healthcare, automotive, and aerospace industries. It comes gift-wrapped by the GS1 US, too!

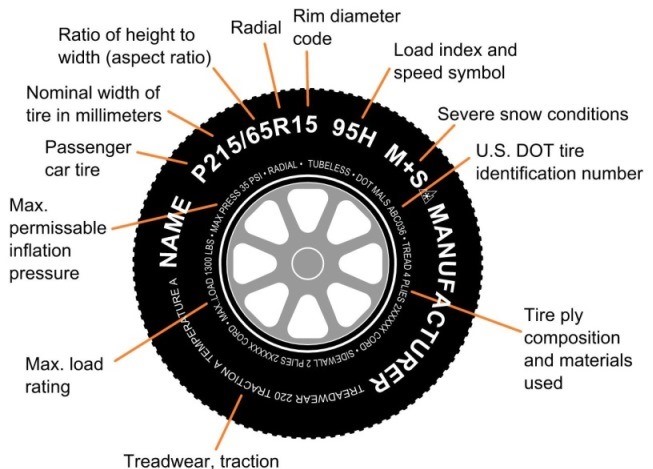

The TIPP approach bears an analogy to car tire codes. The standardized information on the tire sidewalls describes the fundamental characteristics of the tire and is mandated by US Federal Law and EU Directives. Adapting to this system, the car manufacturer carefully masters the product (car) design, sets the tire requirements with a few alternative sizes that the car owners then follow. Periodically there is the unbiased 3rd party to check that a particular car has tires that meet the specs, are not damaged nor too worn out. In all these technical affairs, the tire manufacturer’s responsibility is to come up with the numbers and put them on the product. The tire brand is devoted to the sales and marketing side of things.

Tire sidewall markings include plenty of information for the consumer. “Tire code – en” by F l a n k e r – Own work. Licensed under CC BY 3.0 via Commons.

I will take a second example also from the automotive industry: SAE oil grades. Most car makers don’t endorse Total, Shell, nor Valvoline above others, but simply specify multigrade SAE 5W-30 in the owner’s manual, perhaps with little twists as BMW-LL-04. These grades have temperature-viscosity built-in, which makes a real difference up here in the North Pole. This valuable classification work was done by the Society of Automotive Engineers – SAE, which also has set standards on the quality side. SAE oil grades lay the grounds for easy purchasing, healthy competition, and results in fewer engine problems for us all. In this setup, the oil brands play an important role that is simply fenced off from the underlying oil grading system.

These two examples illustrate how grading systems have made two major industries more transparent, efficient, and streamlined. Sure it took years to develop and enforce these common practices, but the outcome benefits everyone.

Maintaining Approved Inlay Lists Becomes Too Complicated as RFID Tagging Expands to New Product Categories

Before the TIPP was established, the early adopters of RFID came up with their ways of getting tagging done in a controlled manner. Often this meant countless hours of the trial-and-error type of testing, and the outcome in many cases was lists of approved inlays that are suited for a particular product category. Suppliers were then instructed to use inlays from those lists, and just for a while, the process seemed to be alright.

Gradually the pain started to manifest itself. Because an inlay product is in constant evolution, maintaining of inlay lists often turned out to be quite a burden. To make the situation even more uncomfortable, the amount of testing is dramatically increasing as RFID tagging expands to new product categories. Even suppliers were unhappy due to extra effort and expense because conflicting lists from different retailers lead to exception tagging.

Adopting TIPP Is Evident, But There Are a Few Speedbumps Left on The Road

GS1 US did a fantastic job in pulling retailers, suppliers, and RFID industry experts together, and as an outcome, the TIPP grading system with eight initial performance grades was introduced in January 2015. The test methodology was documented on the protocol, physical and practical levels. A logical and well-documented alternative to the approved inlay list processes had been introduced.

So why is it that the US retail’s giants did not instantly adopt TIPP? I would list four factors:

- The TIPP grades are not intuitive – which one to pick, and what to do if none of the eight alternative grades meet the read scenario requirements;

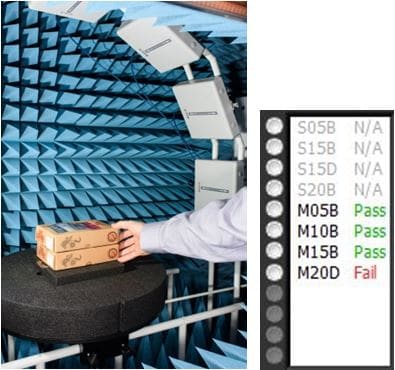

- How to verify for the TIPP grades – RFID technology vendors have not yet introduced routine validation methods for TIPP graded retail items;

- Many retailers are managing global supply chains, and they would rather adopt a global standard around RFID tagging;

- From the perspective of a multi-billion dollar retail company, slowness is an integral part of “instant”.

All these issues can and will be resolved; it just takes time. The road ahead is, therefore, paved with education, training, convincing, waiting, and politics. This rough terrain is nothing new since most RFID vendors are ideally used to it already for a decade.

The Industry Is Multitasking And Making Further Progress

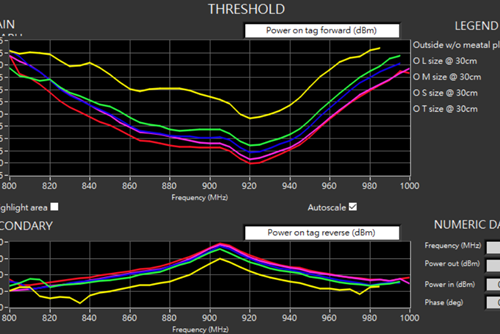

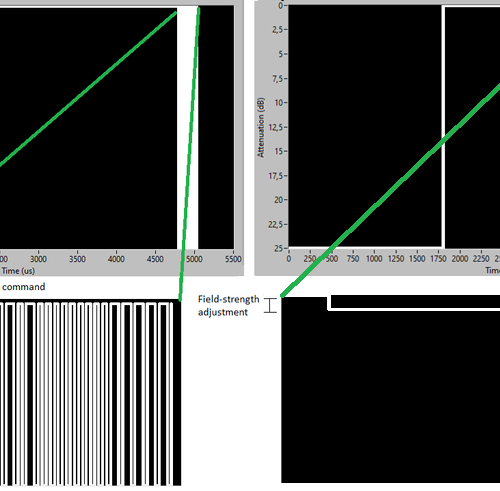

The vital steps that technology vendors and GS1 should take include making the TIPP grades more understandable, adding new grades in the portfolio, and introducing validation methods. All these issues are being addressed as we speak. In fact, for validation, there are already the first out-of-the-box solutions available, as you can see from the videos below.

On top of this great news, the GS1 Global Office is making a strong effort to develop a TIPP global standard. Retailers in the US, Europe, and Asia should all contribute and support GS1 in getting the global standard out promptly.

All this takes time. Many stakeholders are working on it, and it’s going to turn out great. Please contact me (juho.partanen@voyantic.com) for further insight!

All blog posts