Tagsurance® UHF

RFID Measurement System for Fast Tag Testing in Production Lines

The end-of-life schedule has been announced for Tagsurance UHF. Read the notice here ›

Tagsurance 3 replaces older Tagsurance Products.

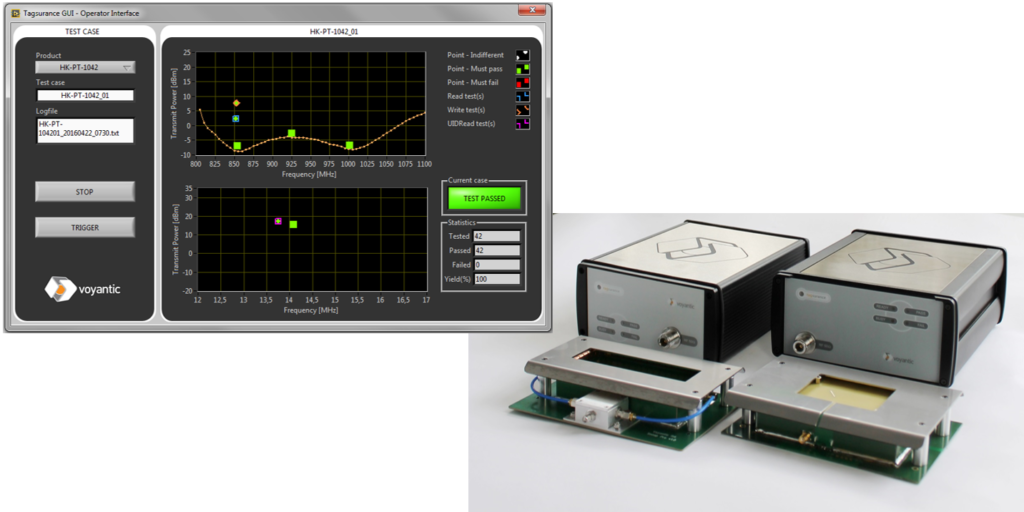

Voyantic Tagsurance® UHF characterizes UHF RFID Class 1 Gen2 tags in a predetermined time frame. Testing with the Tagsurance is based on communication with the tag on several frequencies on a wide frequency range, which allows verifying the tag’s performance, not only checking if it is functional. Tagsurance is the equipment to assure that the production quality corresponds to the designed quality.

Active, Wide-frequency Performance Testing

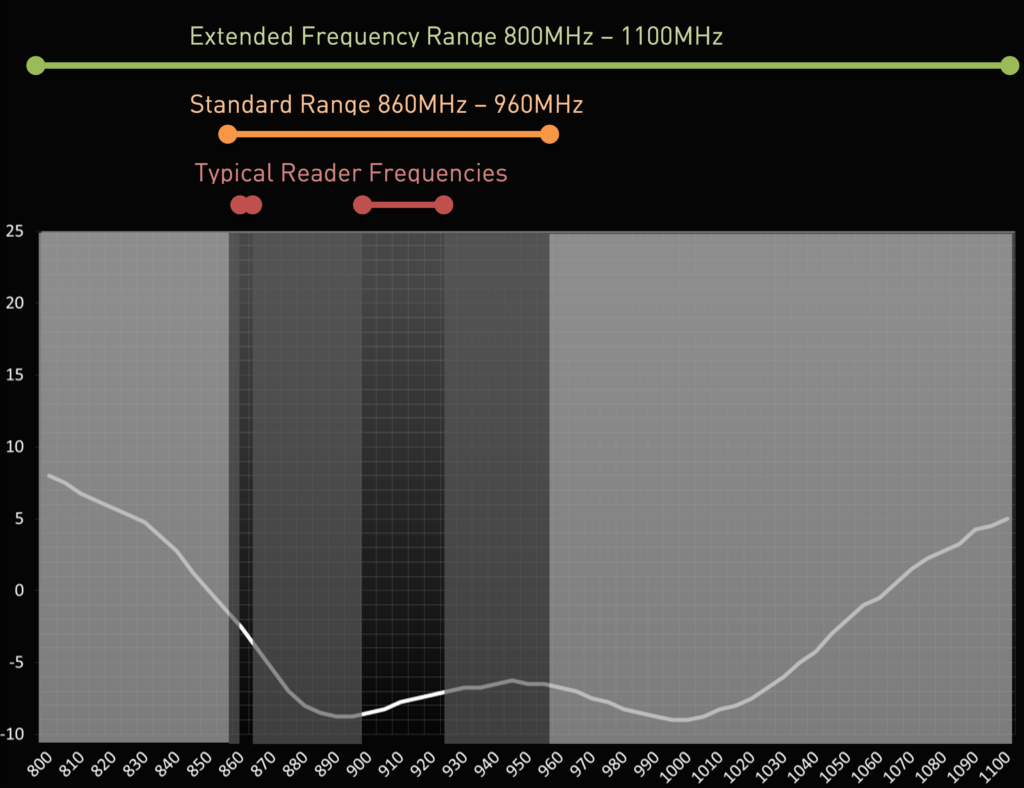

Traditional reader-based testing is limited to a narrow frequency range, with limited visibility to the tag quality. Due to the tag design peculiarities and detuning effects occurring on a roll and in the near-field, tag performance needs to be tested in a wider band, and the frequency of interest typically is outside the traditional reader range.

Tagsurance enables testing the tags’ ability to communicate on multiple frequencies throughout its operational band using frequencies 800-1100MHz (RAIN RFID).

Fitted to Integrate with Production Process

Tagsurance test system provides several simple integration options and scales from single-lane to multilane and wide web test applications. Several test modes are available to allow appropriate test coverage and testing speed time with the process requirements. The product family supports RAIN RFID and NFC testing, and can also be used for dual-frequency tag testing.

Reliable Quality Assurance

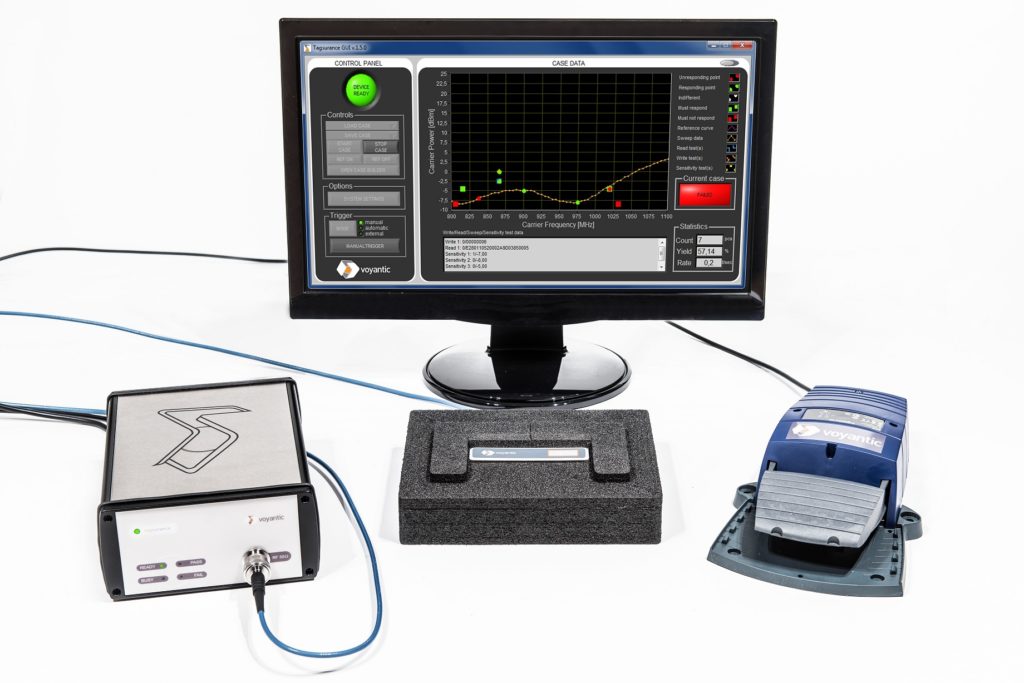

The Tagsurance system with the Snoop Pro coupling element provides reliable and accurate quality data even in the fast-moving process. By using the Tagsurance system, you know that each tag performs as specified. Reliable data generated in the test is valuable – whether you are buying or selling the tags.

Production Testing Solutions

The Tagsurance product family takes accurate performance testing into production. Tagsurance solutions cover the production testing needs from manual testing to fully automated in-process testing.

Wide frequency range: visibility to performance and quality variance

Calibrated: accurate and reliable

Efficient and fast production and quality assurance

Local Language Support in GUI: English, Spanish, German, Finnish, and Chinese

Adjustable: integrable with the production process

Versatile: single lane, multilane, machine integrations, and manual test station use

Decreased waste with real-time visibility to process performance

Easy: simple integration, low maintenance.

Perfectly functioning RAIN RFID systems with 100% performance tags

Improved supplier-customer relations backed with accurate and reliable data.