It has been almost a year since the Tagsurance 3 launch. So we thought it was about time to report what we’ve been up to with Tagsurance 3 product development and tell a bit more about the product vision and next steps.

I summarized the new features since the launch below. These are made based on customer feedback, our learnings from the market and to enable robust industrial-scale quality control on most production lines.

We are committed to providing the best quality control solution for RAIN RFID production lines from chip attachment and label converting to offline reel-to-reel, and even for tagged items. Our focus is on creating a fast, reliable, scalable, future-proof, and modern quality testing solution that is also easy to integrate.

We will continue full-steam ahead on this track.

We are also working on RAIN encoding. It will be a feature in Tagsurance 3 so the same well-known platform, same team, and same ambition will soon cover RAIN encoding as well. The encoding feature can be upgraded to your current or future Tagsurance 3 installations. More information on the release schedule and specifications will follow.

Oh, and almost forgot to mention that Tagsurance 3 version 3.5 was just released, see the details here: https://voyantic.com/download/tagsurance-3-download-page/tagsurance-3-5-0-download-page/

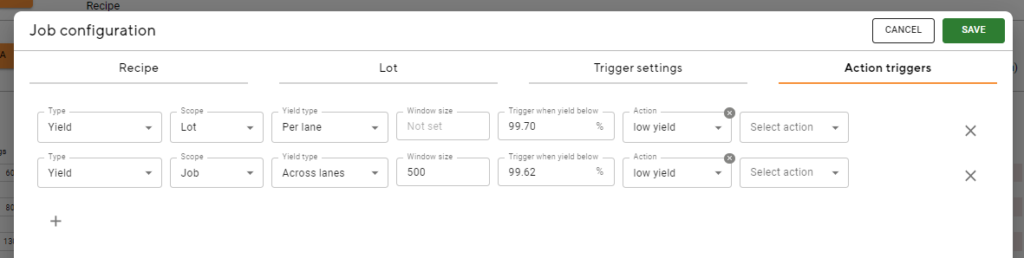

IO signals to the production machine based on yield

This feature brings the possibility to give a digital IO signal to the machine or LED signal tower based on low yield or consecutive failed tags. Here are a few examples:

- the yield of current lot/job per lane or across lanes, e.g. lot yield < 99.21 %

- the yield of a “window”, e.g.

- last 400 tags < 99.1 %

- can be used to stop at n consecutive failed tags;

- set window size to match wanted “max consecutive fails”

- set yield percentage (X) as follows: 0 < X < 1 / [windows size] * 100

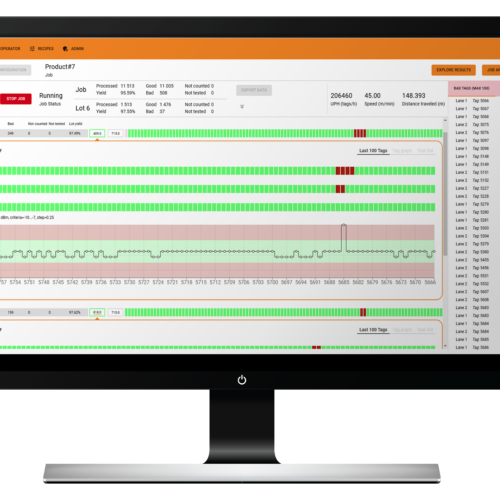

Telemetry visible in operator UI

This feature shows lane speed and distance traveled since the job start. You can also trigger sensor-related data in real time:

- pattern correlation if the pattern in use

- pitch measured based on trigger

IO only station

The IO-only station feature is useful for integrating, for example, a machine vision system for visual quality check or a similar test device that is either triggered by itself or by Tagsurance 3.

The IO-only station works like any other station with the exception that no data connection, no initialization by Tagsurance 3, and no results as data (only pass/fail) in Tagsurance 3.

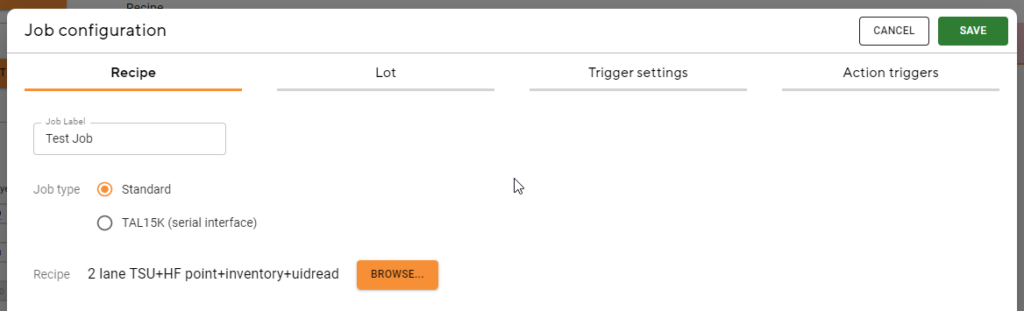

Job configuration in one place

All configuration items (recipe, lot, trigger settings, and action triggers) needed for a job are now in a single modal and easy to manage.

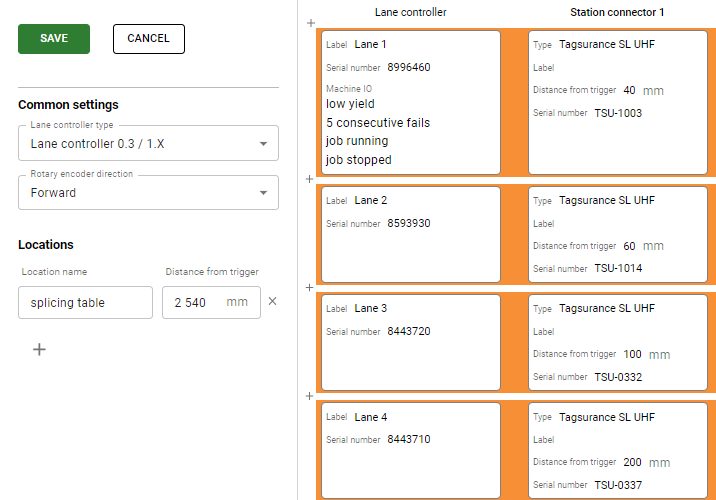

Lane Configurator is now part of the operator UI

The machine IO and Locations settings have been moved to Lane Configurator as well, putting them all logically in the same place.

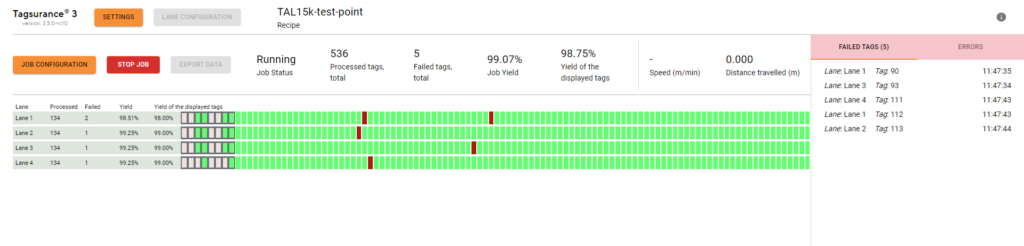

TAL15k support “RS-232 tester interface”

Tagsurance 3 can be now used with the Mühlbauer TAL15k machines with either one or two testers. The latest version provides full support for the TAL15k including operator UI and a real-time view of how the testing progresses in the testing area.

If your TAL15k has the “RS-232 tester interface” enabled (we will help you to find this out) then Tagsurance 3 can be integrated to TAL15k machines very easily, just by connecting the RS-232 from the machine and changing the coupling elements to Voyantic Snoop Pro.

Strobe light (LED) available as an accessory for easy trigger adjustment

The strobe comes with a short adapter cable and it is connected between the “Station IO cable” and the “Station”.

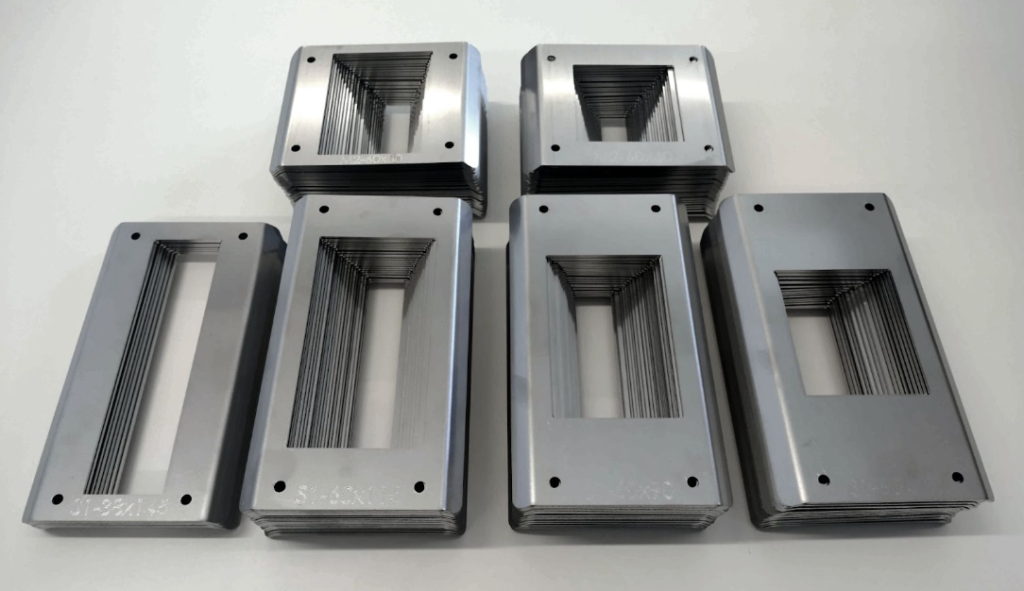

Snoop Pro shielding plate collection has grown significantly

Snoop Pro 1.0 and Snoop Pro Mini 2.0 have now a large collection of shielding plates available to purchase to avoid compromising lane speed and/or testing accuracy. New plates also have the type and opening size engraved on them for ease of use.

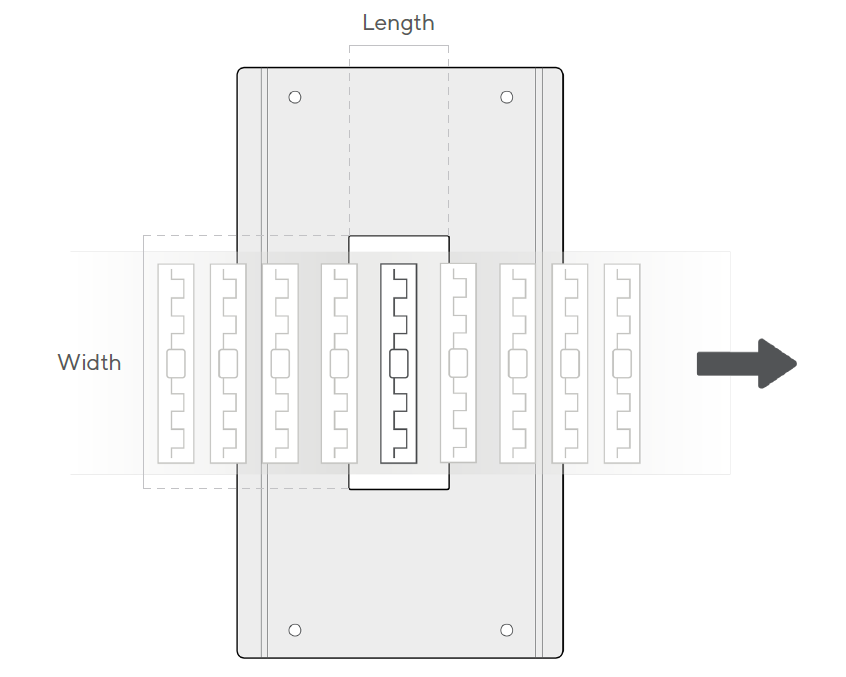

Notes on the terminology:

- The length of the shielding plate opening is always the opening dimension in material movement

- The width of the shielding plate opening is always the opening dimension perpendicular to material movement

- Snoop Pro 1.0 selection:

- 70 mm width – lengths from 24 to 60 mm in 2 mm steps

- 90 mm width – lengths from 20 to 60 mm in 2 mm steps

- 115 mm width – lengths from 24 to 60 mm in 2 mm steps

- Snoop Pro Mini 2.0 selection:

- 60 mm width – lengths from 16 to 60 mm in 2 mm steps

- 80 mm width – lengths from 16 to 60 mm in 2 mm steps