RAIN RFID use has grown rapidly and implementations are expanding. Nowadays RFID is business as usual and quality management is an essential part of normal business operations. In past few years the RFID industry has learned a lot about quality management methods and processes. In my opinion there is still room for improvement. Quality really matters in RAIN tag manufacturing as high readability of tags is expected practically in all applications. In this text I describe how some quality management principles relate to tag manufacturing.

Continual Improvement in RFID Tag Manufacturing

One of the key principles in ISO 9000 quality standard series is continual improvement and accordingly

- quality must be measured;

- results need to be analyzed; and

- operations will be improved.

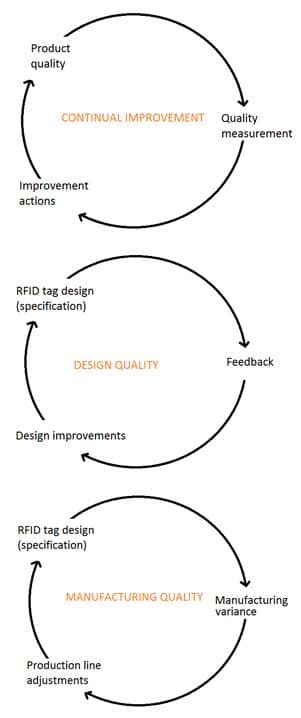

There are two ways to look at the quality:

1 – Quality of design is measured against the properties (e.g. features, functionalities, performance) the supplier intends to deliver to the customer. Improvements can be driven for example by new kind of customer requirements, changes in competing products and availability of new components.

Typical performance measures for RAIN tags are sensitivity/read range and orientation pattern, performance on different materials (tagged items) and in proximity of other tags. Additionally, for example memory options, command support, mechanical design and dimensions and durability are ingredients of design quality.

Improving Quality of design is responsibility of the R&D and usually requires new product development, e.g. modifying the antenna geometry. Improvement cycles are relatively long.

2 – Quality of manufacturing describes how much variation there is in performance of the key properties compared to the defined design quality.

In RAIN tags the typical measure of quality is sensitivity. For example: Sensitivity of the tag attached to PVC plastic, with 915MHz frequency is -20dBm +/- 0.5dB. In this example the -20dBm is design quality and +/-0.5dB is variation describing manufacturing quality.

In managing Quality of manufacturing the performance is measured by the quality organization and corrective actions can be implemented very quickly.

The basic methods for controlling quality in tag manufacturing are sample testing and continuous in-line testing.

RAIN Tag Manufacturing Quality Control

One single solution doesn’t fit all RAIN tag manufacturing processes, but the principles of applying either sample testing using an off-line tester or implementing the tester into the production machines to enable 100% in-line testing are universal.

Sample Based Testing

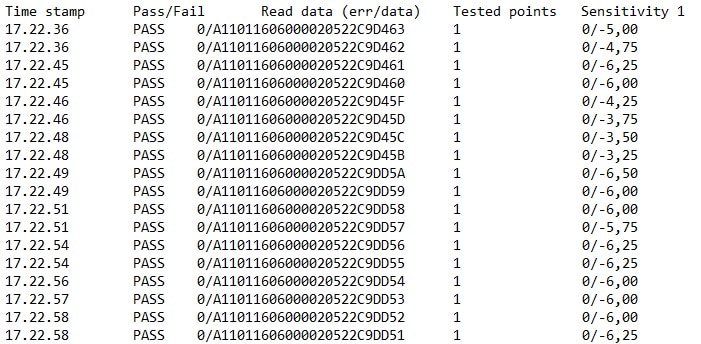

For example, with 100,000 tags daily production, 99% confidence level with 2% margin of error requires about 4,000 tags to be tested. In practice, 1-2 tested tag rolls per day per manufacturing line would be the statistically valid sample size. Voyantic Reelsurance handles the testing automatically after the testing is initialized. Several rolls per day can be tested with one machine, and the system produces full quality logs. Reelsurance is an example of an off-line reel-to-reel tester capable of testing RAIN tags either in inlay or label form. The testing capability is based on integrated Tagsurance tester.

100% Testing and Quality Log

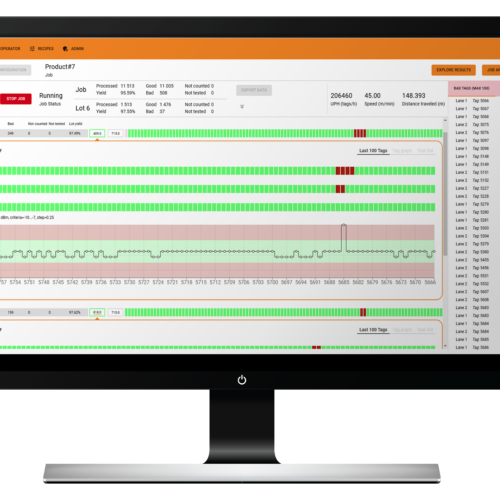

Voyantic Tagsurance tester can also be integrated with various manufacturers’ chip attach, converting or personalization machines enabling 100% testing.

The testing creates a log file that can include TID and EPC codes of the tested tags, as well as test results. This is a handy tool for communicating 100% test results. The data can be used for finding out statistical information from the manufacturing quality: variation, standard deviation, percentiles, mean values.

Real-time Visibility to Production Quality

When information is available for the production line operator real time, it is easy to see when quality starts to deviate, and corrective actions can be taken immediately, without sacrificing production yield.

RFID Tag Manufacturing and Six Sigma

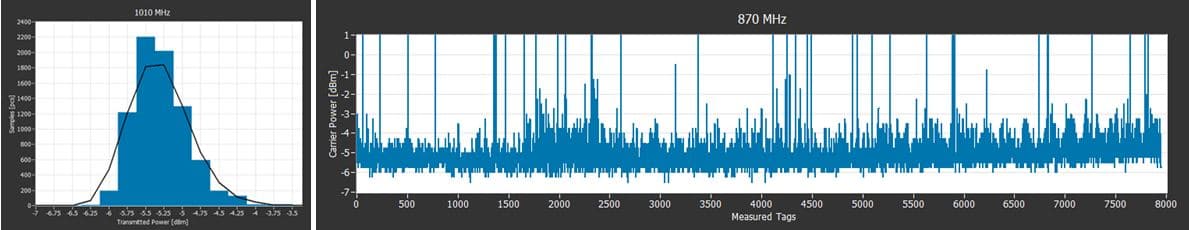

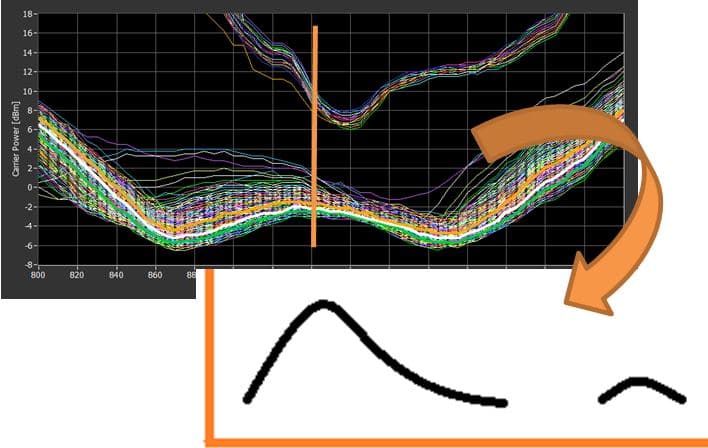

A typical output from a tag manufacturing process used to be skewed normal distribution with additional second peak as shown in the picture across wide frequency band: the “stray” tags made it impossible to implement Six Sigma to the letter. Instead, deviating tags can be sorted out, and Six Sigma limits may be used for the remaining part.

Developments in new RFID chips have changed the situation. Some tag models can be manufactured with normal distributed sensitivity variation. It is possible to implement Six Sigma quality control, maybe with 4-sigma limits to start with.

Contact us to arrange an online demo and to discuss more about quality control in RAIN RFID tag manufacturing!

Quality Testing Solution for RFID Label Production

Tagsurance 3 is the next-generation quality control solution for high-speed RFID inlay and label production lines.