During this COVID-19 pandemic, as most airplanes are stuck on the ground and several large airplane orders have been canceled, aerospace is probably not considered the hottest market for RAIN RFID. However, eventually, this situation will pass, and more airplanes will be built. When that happens, the aerospace industry will be more ready than ever to use RAIN RFID, due to recent standardization work.

Back in 2015, I wrote about the aerospace industry as the pioneers of RFID:

“The aerospace industry realized that they need standardization for flyable tags as early as 2006. That is when a group of experts in the field decided to develop a standard under SAE International. SAE AS5678, “Passive RFID Tags Intended for Aircraft Use”, was born … In addition to environmental testing, the standard also describes RF performance tests for the tags. The standard described a very professional and well repeatable measurement methodology. But even more interestingly, the standard divided tag performance into performance grades, somewhat similarly to what the GS1 TIPP standard would do for the retail industry in 2015.”

Fast forward to 2020, in February, SAE published the third version of the standard, AS5678B Passive RFID Tags Intended for Airborne Equipment Use. So, what’s new in the standard revision?

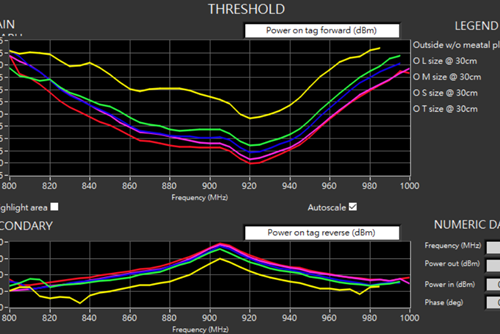

The changes are mostly related to how the performance grades are defined. In earlier versions of the standard, tags were graded based on their read range, determined from their sensitivity. And that makes perfect sense: In 2006, the sensitivity of RFID chips wasn’t that great, and read range was nearly always limited by power delivery to the tag. Nowadays, that is not always the case. As the sensitivity of tags has improved, in more and more cases the return link from the tag to the reader may limit read range. This is reflected in the new standard revision; in AS5678B, the grades are determined by both minimum read sensitivity and minimum backscatter.

To give an example, for a tag to be classified for Grade X, the sensitivity of the tag on a metal plate has to be better than -12 dBm, and its backscatter strength needs to be at least -23 dBm. That corresponds to an expected read range of 6 m. But that’s not all. Because airplanes are expected to cross borders, and radio regulations are different in different parts of the world, this performance is required throughout the global RAIN RFID range of 865 to 930 MHz.

There is one more new element in the standard. It is no longer sufficient for one individual tag to pass a grade – a statistical element is introduced. A total of 30 tags needs to be tested, and their performance variation must be below a level defined in the standard.

Overall, I am quite happy with the new standard revision. With the new backscatter criteria, it is well in line with the development of the industry. The backscatter is required to be quite strong which means that most readers are able to read tags that meet the criteria – and that is probably a good approach. In addition, the statistical test brings a hint of a quality aspect to the standard.

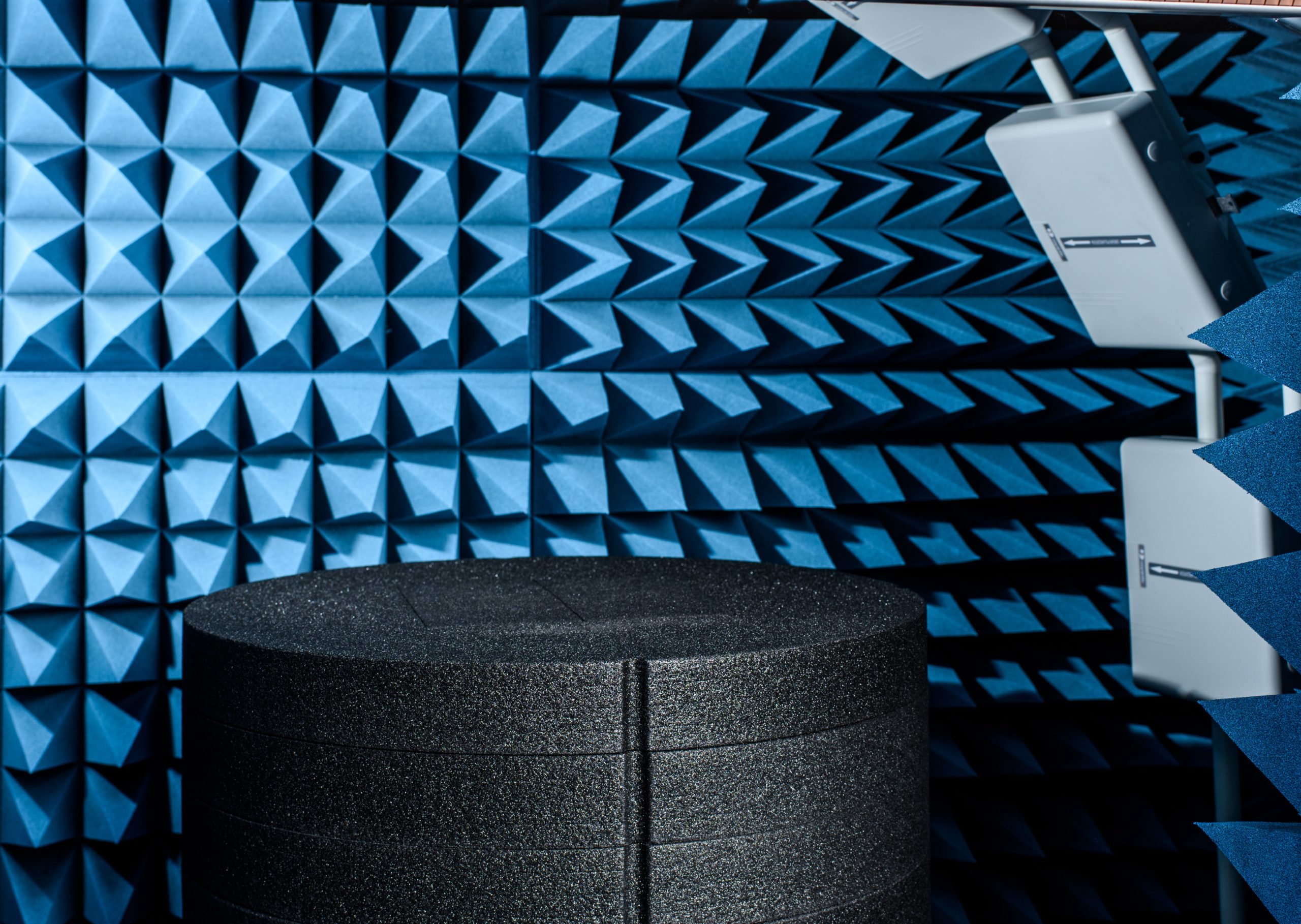

As a final thought, there is one thing that I find curious about AS5678. No one is openly advertising to offer test services according to this standard. Customers often contact me to ask for a service provider. Some tag makers are obviously either testing their tags themselves or having them tested somewhere. Probably most of them use an external lab for the environmental testing and do the RFID part with their own Tagformance system).

But wouldn’t it make sense to have a one-stop-shop for AS5678B testing?

If you think that a lab that you know should start offering these tests, please let us know. If they already have the environmental part, we would be happy to help with the RFID part.

Learn How to Test UHF RFID Tags in the Aerospace Industry

Download The Essential Guide for UHF Tag Testing in Aerospace