Retail RFID seems to get the most limelight in the RFID industry at the moment. And that is not surprising because of its huge tag volumes and growth rates. But many other sectors are benefiting from RFID use as well. One of my personal favorites is the aerospace industry.

The most visible aerospace company in the RFID space has been Airbus. Their announcement, at the beginning of this year, to ask their supply base to tag all traceable items with passive RFID shows that they are serious. But also Boeing and Embraer come across regularly in RFID related news. To serve this industry, an ecosystem of RFID technology providers has emerged. Companies such as Fujitsu, Maintag, Tego, OAT Systems, and Brady, to name a few, have a special focus in aerospace RFID. Besides, the ecosystem has generated business opportunities for the supporting industry, see, for example, the Stanley Black & Decker success story.

What is Required from RFID in Aerospace?

So why are some RFID companies specializing in the aerospace industry? Can’t we just buy a roll of RFID labels and start tagging airplane parts? Well, it is not quite as simple as that. Several aspects set aerospace RFID, apart from many other application areas:

- Large memory required: The aerospace industry requires that a lot of information (birth records, maintenance records, etc.) is stored directly into the tag. They don’t want to rely on a connection to an external database which is usually used in retail RFID.

- Valuable items: The tagged items are of high value and are often used for ten years and more. As a result, tag durability is more important a driver than tag cost.

- Harsh conditions: Tags in and out of an airplane need to endure vibration, significant variations in temperature, humidity, and pressure, and many other conditions unfamiliar to retail applications.

- Global functionality: As airplanes frequently cross country borders and oceans, the RFID tags need to be readable around the world. As a result, the tags must be designed to be wideband.

- Less sensitive tag ICs: Due to their larger memory content and possible special functionalities, the tag ICs used in aerospace typically need more power. As a result, many applications are limited to read ranges of 15 cm to 3 meters.

A Need for Standards

The aerospace industry realized that they need standardization for flyable tags as early as 2006. That is when a group of experts in the field decided to develop a standard under SAE International. SAE AS5678, “Passive RFID Tags Intended for Aircraft Use” was born. The standard includes a broad set of different environmental tests to make sure that a tag would endure the harsh conditions of a flying airplane. Sun APT Test Center was the first lab to start certifying tags according to the standard.

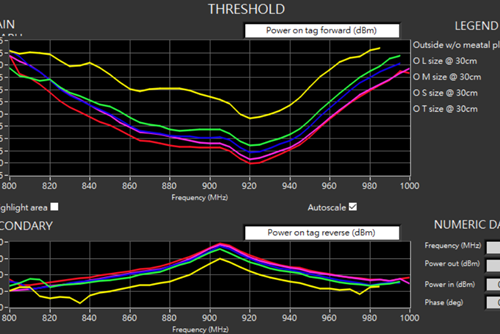

In addition to environmental testing, the standard also describes RF performance tests for the tags. The standard described a very professional and well repeatable measurement methodology. But even more interestingly, the standard divided tag performance into performance grades, somewhat similar to what the GS1 TIPP standard would do for the retail industry in 2015.

AS5678 was truly ahead of its time.

As a result, an airplane manufacturer could simply require a grade B tag to be used by its suppliers without having to specify the tag model or detailed performance parameters.

Now, in 2015, SAE is revising the AS5678 standard to reflect the new information gained during the years. I have been a member of the team, revising the standard as well. The changes, however, are not very large, which well reflects the quality of the first standard version.

Specific RFID Testing Needs of the Aerospace Industry

The special requirements of the aerospace industry for RFID lead to some specific testing needs:

- Measuring tag performance: Because of the large memory contents, wide bandwidth, and rugged design, aerospace tags may have limited read ranges. The AS5678 test methodology can be used to determine the acquired read range and the matching performance grade.

- Verifying tag bandwidth: Since a wide bandwidth is required, the performance of the tag needs to be tested typically throughout the 860-960 MHz frequency range.

- Environmental tests: AS55678 describes a large set of environmental conditions that the tag needs to endure. The performance of the tag should not degrade during the tests.

- Memory testing: The memory of an aerospace tag is organized differently compared to a typical label. As a result, there is a need to have good visibility to the tag memory contents.

My company Voyantic has delivered test and measurement systems for both end-users and technology providers in the aerospace RFID industry. The systems promote design and manufacturing excellence, as well as fluent technical dialogue between pioneering companies within the industry.

If you are interested to learn more, please download our application note below or contact us, and let’s talk more!

Learn How to Test UHF RFID Tags in the Aerospace Industry

Download The Essential Guide for UHF Tag Testing in Aerospace