When there is a need to increase smart label production volumes, it can be done by adding new machinery, more lanes to existing machinery, or by increasing production speeds. All these methods are in use, and they are combined frequently. For example, new production machines have more lanes and higher lane speeds.

At Voyantic, we are seeing that increasing lane speeds combined with smart label component development has put durability testing into the spotlight. In this article, I analyze the reasons behind the increased interest in smart label durability testing, and I will share the basics of the test methodology.

Why is the interest in durability testing increasing?

I believe that part of the increased interest can be seen as a healthy sign of technology maturation and market growth. RAIN RFID and NFC just work. Technology suppliers do not have to fight with the basic functionality and the focus is shifting to scalability. Outside of some special use cases, durability has been taken as given.

Let’s have a look at the drivers that are now challenging label durability.

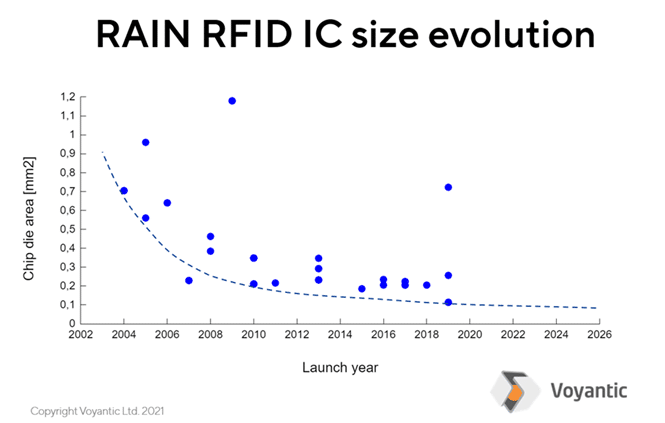

Decreasing IC sizes

The latest generation of RAIN tag ICs is becoming smaller. When ICs are getting smaller, a natural question is what happens to the connection between the IC, the antenna, and the liner. And what is the effect on the inlay durability?

The transition from plastic to paper-based labels

Due to ecological aspects, paper is used increasingly as label base material. The “stickiness” of antennas and ICs to paper is different compared to a plastic liner. Paper also stretches and bends differently than PET.

All paper is not just paper, but different additives and fillers are used to create different properties. All these properties, whiteness, polishing, and so on, may affect how the antenna and IC stick to the paper. Finally, add humidity as an environmental variable, and the durability of the paper-based label needs to be studied for sure.

Faster IC attach processes and new bonding epoxies

IC attach machine speeds keep on increasing and the machine vendors are working their way towards 100,000 UPH. The stress to an inlay with a freshly attached IC is higher when lane speeds increase. There is also less time to cure the bonding glues, which has led to new glues being introduced. These new glues require less time to cure, but may need higher curing temperatures. Again, a question about durability comes up: How to fine-tune the bonding process so that the label durability is not compromised?

Faster converting machines

Converting process speeds are also increasing. Higher machine speeds stress the inlays and labels. An obvious worst-case to avoid would be inlays starting to break already during the converting process. Do the inlays survive intact through these fast processes?

Label type NFC tags

Traditionally a label has been one of the major RAIN RFID tag formats. NFC tags have been made more as smart cards, various key fobs, and other more rigid formats. Lately, NFC label production has also started to grow. This extends the label durability question from RAIN RFID to also NFC. Are NFC labels also durable enough to survive through the label life cycle?

All the above changes are happening in parallel. The combined outcome is what matters. Are the inlays durable with all the new materials, components, and processes?

Standard durability test method

Test principles

The basic principle of durability testing is to compare a meaningful parameter before and after a stress, and to analyze the results to determine whether the stress creates unwanted consequences. Because the tags under testing are stressed, potentially to the point of breaking them, the method cannot be used for testing every individual tag. It is rather used to test the designs, and indirectly the manufacturing processes.

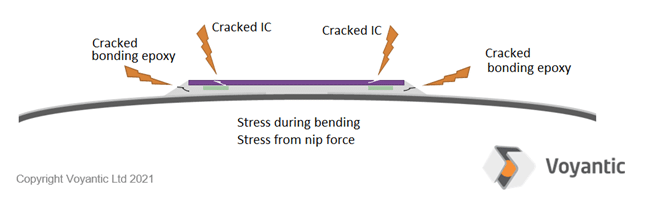

For many electronics products, heat cycling is a standard durability test method. Also, drop tests, pressure tests, tumble tests, and shear tests are frequently used. For smart labels, the default test method is bend testing. The need for bend testing comes from the typical smart label failure methods.

The two most likely points to fail in smart labels are chip bonding and the edges of the IC. Bend testing is a way to verify the sufficient durability of both of these possible failure points.

Test method

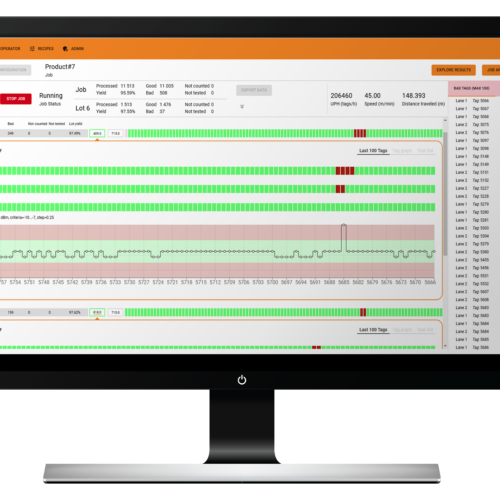

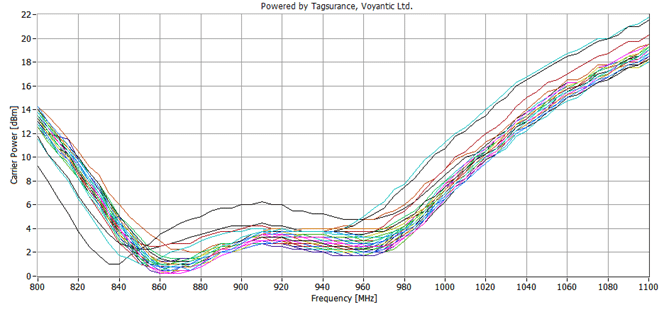

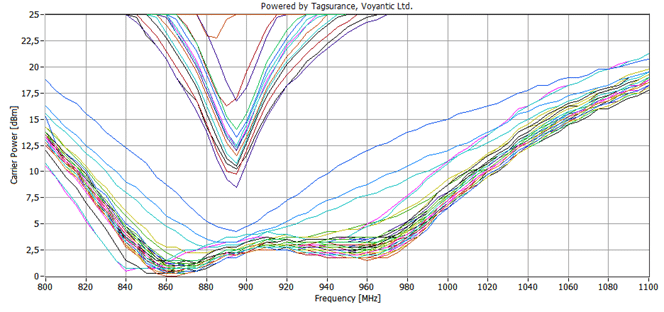

At the beginning of the test, a baseline performance needs to be measured. The baseline performance of the sample set consists of the threshold sweep result of each of the tags in the sample. The threshold sweeps can be done with Voyantic Tagsurance® devices. The curves describe how much power is needed for waking up the tags at different frequencies.

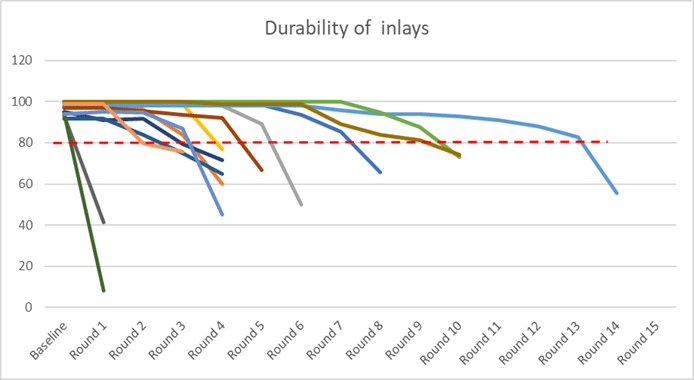

After the baseline test, stress is applied to the tags, and then the tag performance is tested again.

This cycle of test rounds and stressing the labels are repeated until a targeted performance decrease has been reached. The more test rounds an inlay (label) survives, the better is the durability test result aka durability rating.

The test method document describes the details of the test parameters and stress parameters.

Download the detailed standard test method description

Special tags

There are some special tags where bend testing is not (the only) relevant durability test method. For example, aerospace tags are tested according to the SAE AS5678 standard, which defines environmental conditions such as temperatures, vibration, etc., which the tag must sustain. With these standards, the tag is stressed with vibration and extreme temperatures instead of the typical bend testing, which is designed to highlight the common failure methods of cracked bonding and cracked ICs.

The same test principles can also be combined with other durability testing methods. For example, laundry tags could be tested using ISO15797 standard, which defines how garments are stressed with washing cycles. The idea is the same: to find out whether the tag performance decreases too much when stress is applied.

Also, specialty tags that are intended to be used in extreme conditions, exposed to heat, cold, or chemicals, should be tested in combination with applicable stress methods. IEC60068-2 standards (environmental testing of electronics products) provide help for these. IEC60068-2-2 (dry heat) and IEC60068-2-14 (temperature variation) are likely useful methods, and both can be combined with Tagsurance testing. The IEC60068 family also includes test methods for different mechanical stress types, chemicals, humidity, and so on.

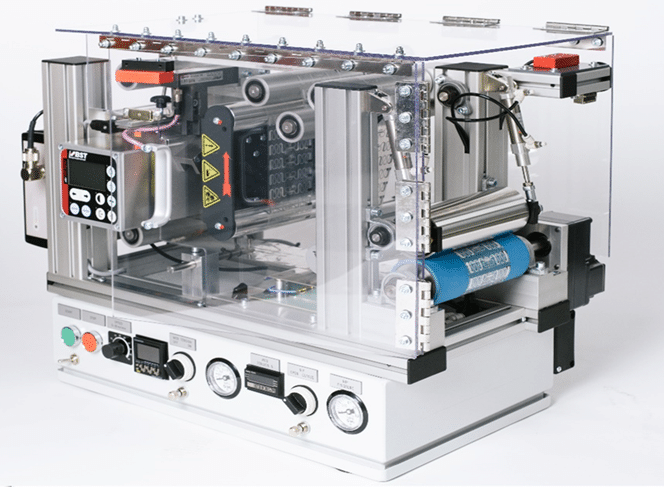

In these special tag durability tests the RFID testing, both baseline and the test after stress, can be made with Tagsurance® systems. Between the RF tests, different stress is applied with the Voyantic Bendurance machine.

How durable is good?

An obvious question related to durability testing is: How durable is durable enough? Or: How durable is good and what is not good enough?

There is no clear answer to these excellent questions. Laundry standard ISO15797 has its criteria and a way to define what is durable enough. SAE AS5678 similarly has its criteria for aerospace tags. But those criteria cannot be extended to other use cases and tag types.

One answer could be: Durable enough is when a smart label survives its intended life cycle. That answer does not help in practice.

Another way is to look at comparison data. It doesn’t give a simple answer but probably helps in practice. If an inlay is as durable as others, most likely it is durable enough. And on the other hand, if an inlay is less durable than a typical inlay, a closer look should be taken, and possibly an improvement is needed.

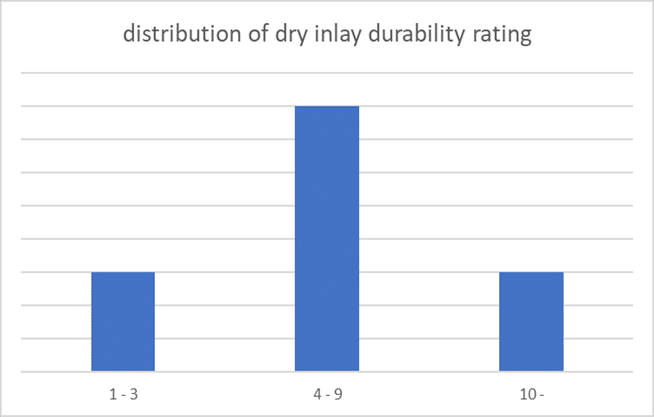

Comparison data in mind we tested some dry inlays with the following results.

There were significant differences in the dry inlay durability. With the weakest dry inlay model, over 90 % of the inlays broke beyond specified performance with the first test round. The strongest inlays survived more than 10 stress rounds.

- About 20 % of the dry inlays got a durability rating of 1-3

- About 60 % of the dry inlays got a durability rating of 4-9

- And about 20 % of the dry inlays got a durability rating of 10 or higher

- Median durability rate for all the tested dry inlays was 4, and average about 5.5

This suggests that dry inlay durability could be considered typical if the durability rating is between 4 and 9.

Summary

Faster manufacturing machines and new materials have increased the need for testing the durability of RAIN RFID and NFC inlays.

Voyantic Bendurance is a durability test system focusing on bending, the typical failure mechanism of the inlays. Bendurance with its standard test method gives comparable durability data of the inlays.

A similar approach can also be used with other durability testing such as the SAE AS5678 test for aerospace tags, ISO15797 tests for laundry tags and tags integrated into apparel, and IEC60068-2 for durability against extreme temperatures, other types of mechanical stress, chemicals, and so on.

Download the standard test method description

Request a durability test system quotation

All blog posts