For more than a decade, RAIN RFID tag antennas were etched, and the substrate was PET film. Copper was first substituted with aluminum, and various other technologies have emerged, such as printed antennas, and cutting, milling, or laser engraving metal foils.

More recently we have seen antennas being applied on paper and even directly on the packaging and on other surfaces. Much of that development has been driven by cost, but the ecological and sustainability aspects are rising in importance.

Juho Partanen recently moderated an online panel discussion on various aspects and implications of sustainability and eco-friendliness of RAIN RFID tagging. The panelists included Sipi Savolainen from Stora Enso, Jerome Lemay from Decathlon, and Emmanuel Arene from Primo1D. The discussion ranged from ecological tag materials to the technology itself contributing to system-level sustainability through enabling and driving applications for the circular economy.

Watch the panel discussion recording

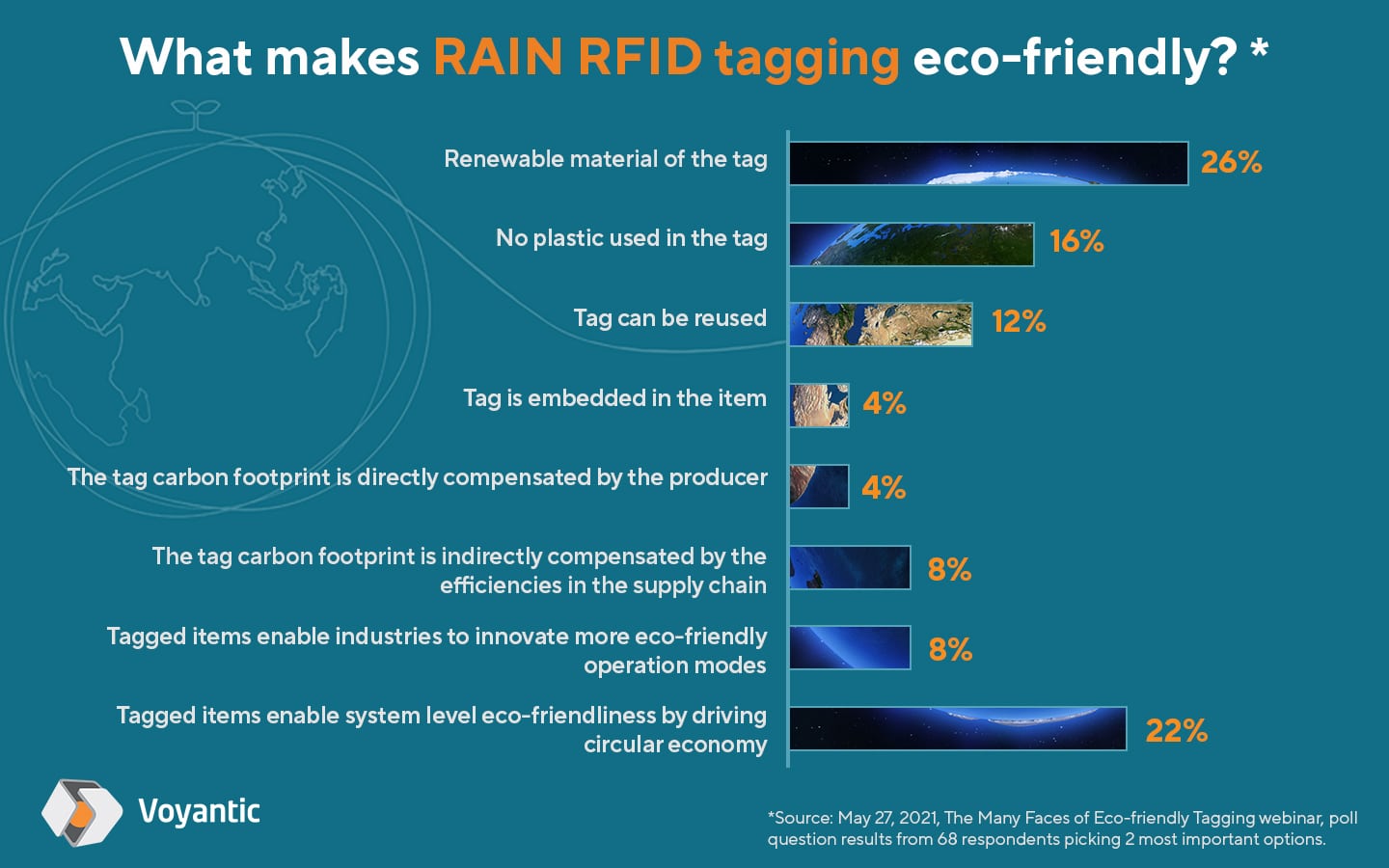

Before the discussion started, we asked the attendees how they would rate various aspects of eco-friendliness? A quick poll revealed the following:

The initial attendee views support the notion that although moving to renewable and recyclable materials for the tags is a no-brainer in terms of eco-friendliness, there needs to be a more holistic view of the whole system – how the technology enables cradle-to-grave traceability, waste reduction, efficiency improvements, transparency plus other aspects crucial for driving the circular economy and sustainable consumption.

We received a lot of attendee questions during the discussion and since the webinar time was limited, we were not able to address them all during the live session. So we asked our panelists to provide some additional answers for this blog.

Follow-up Q&A from the panel discussion

The responses to the following questions have been written by Mr. Sipi Savolainen from Stora Enso.

Question: If a tag is paper-based, could it be placed in the paper recycling bin, as it includes electronics and metal?

Answer: All paper and cardboard recyclability testing is based on the ability to separate non-fiber-based materials from fiber materials and screen those components before re-pulping. According to the results of PTS RH 021/97 Recyclability of Packaging Products and TAPPI UM 213 Repulpability testing (mod.), ECO tags are recyclable within paper and paper board recycling processes.

Question: According to WEEE regulation, RFID label is still regarded as electrical waste, I doubt if the paper-based label can be recycled as paper?

Answer: Passive tags are considered to fall under the scope of the WEEE directive. However, as tags are being attached to items they are naturally disposed with the material/object they are applied to. The best suited waste management process is defined based on the material/object type.

The response to the following question comes from Jerômé Lemay from Decathlon.

Question: What are the most influential factors that can move world businesses towards practicing environmental sustainability?

Answer: For Decathlon, sustainability is considered in a holistic way and, in addition to preserving nature, also includes taking care of people, and creating sustainable value through governance and business ethics, for example. Environmental sustainability is the third pillar and includes tackling climate change and driving the circular economy.

Environmental sustainability needs to be incorporated into the strategy and values, and forward-looking businesses should see that it is also what their customers are expecting.

The response to the following question comes from Emmanuel ARENE of Primo1D.

Question: Obviously, depending on which material the Primo 1D is embedded it changes its perfromance. Is the antenna re-tuned for each different material?

Answer: Yes, the performance of our embedded system is intimately linked to the permittivity of the tagged item. To make sure the RF performance and durability are optimized for each material, object, and use case, different elements can be tuned: the antenna material and its design, the chipset, and the packaging of our RFID UHF tag as well. Primo1D has all resources in-house to support product development and industrialization process till ramp-up.

Panel Discussion: The Many Faces of Eco-friendly Tagging

Listen to expert panelists from Stora Enso, Primo1D and Decathlon wrap their heads around the eco-aspects of RAIN RFID tagging.