Although RFID and metal can be a challenging combination, tagging metal items with RAIN RFID will work as well as any other application, if you choose the right kind of tag designed for metal, and also plan the system and infrastructure carefully. On-metal tags are commonly used in industrial settings, where they need to endure harsh conditions and have reliable performance and readability. It’s great to see how the rapid development in specialty tags helps RAIN RFID usage expand in industries outside of retail.

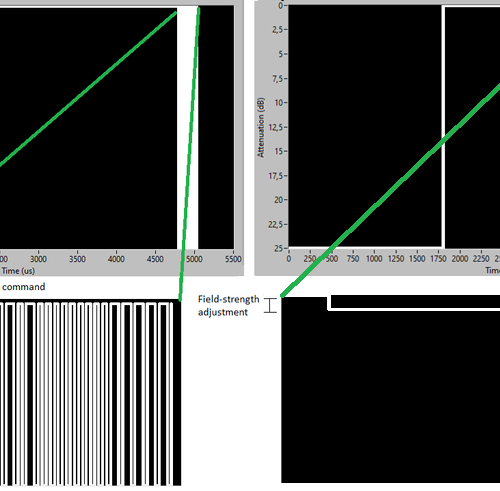

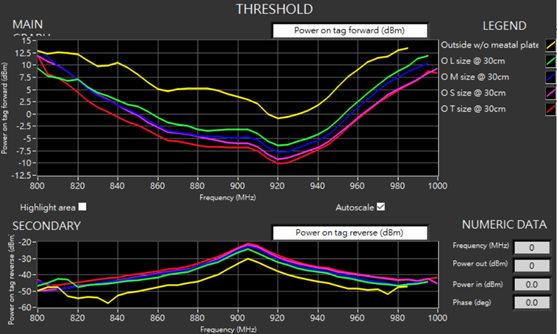

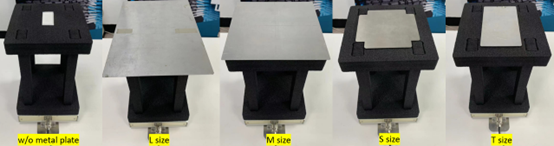

We often get asked for advice on testing tags on metal and other materials. So I decided to make an application note on how you can use Tagformance Pro to measure an on-metal tag attached to a metal plate, both inside and outside an anechoic chamber. I will also discuss the impact of the measurement environment on this application. The interesting question is to see how the performance of the tag change when attached to a metal plate, and how much the form factor of the metal plate has an effect.

In the tests, I used the Voyantic Tagformance Pro system and tested Confidex Silverline Blade printable on-metal labels with four different size metal plates.

Download the Application Note for the Results and Method

To see the full measurement results and learn how I conducted the measurements, download the application note:

Key Findings

To intrigue your interest in taking a closer look at the application note, let me share some findings:

An on-metal tag on a metal plate is highly sensitive to the testing environment, especially outside of the chamber with external RF interference. Testing in an anechoic chamber is thus something I highly recommend for consistency in results.

Secondly, the size and shape of the metal has effects on the performance, thus making tagged-item testing a recommendable step for any metal item tagging project.

Let us know if you have any questions about the application note or using Tagformance Pro for tag and tagged-item testing. We’re always happy to help.

All blog posts