Being responsible for sales of RFID performance measurement solutions, I’ve had the privilege of meeting with several companies and their design professionals around the world using very different methods for measuring UHF tag performance. Which is the best method then? I’d say it depends on your requirements – for a single essential measurement, you may use various methods, and even a simple technique can be sufficient. However, if you are looking for a way to improve the throughput and efficiency of your R&D team in tag design, the differences in methods are enormous. So, where does the efficiency come from?

The simplest method in UHF tag measurement is using an RFID reader to verify if the tag can be read from a certain distance or not. This pass/fail type of method is easy to do and fast for sure. However, most of the critical characteristics cannot be measured nor verified at all. Another commonly used way based on a set of generic measurement instruments like a signal generator, a network analyzer, and a power meter, is more advanced but unfortunately not anymore fast nor easy to use.

As the two methods introduced above are not ideal in the first place, neither of them can be the real solution to provide increased efficiency either – don’t worry, there is another approach available.

Purpose-built RFID Measurement System

In the R&D environment, most RFID measurements set high requirements for reliability, accuracy, and repeatability of the results and the test method itself. This is the case also in developing new UHF tag designs, thriving to the best possible performance, and at the same time balancing various requirements for different parameters. In this kind of environment the key questions are;

- How quickly can a set of various measurements be performed?

- Can the measurements be repeated automatically during the design iterations?

- What are the possibilities in storing, analyzing, and sharing the results?

- What kind of competence is required to perform the measurements?

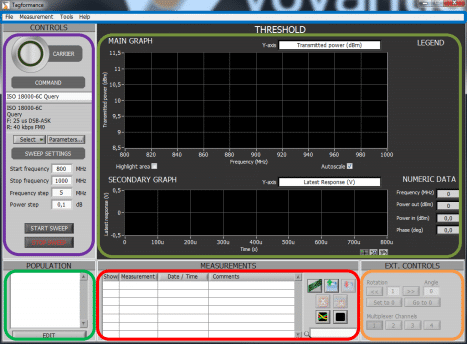

The ideal solution addressing these requirements is a purpose-built RFID measurement system, providing an easy-to-use user interface, high measurement accuracy, compliance with standard RFID protocols, and wideband sweep capability.

How to Enhance the Efficiency of the R&D Team?

Ease-of-Use

There is inherent ease-of-use in the concept of a purpose-built measurement system, as there is only one tester device, including all the necessary accessories and an easy-to-use graphical user interface. A predefined measurement set-up procedure based on a reference tag ensures correct system start and exact measurement results.

Ease of use improves the efficiency of each user regardless of their technical competence. However, the real benefit comes out of the fact that also less experienced persons can easily be trained to perform extensive measurements without having in-depth RF knowledge.

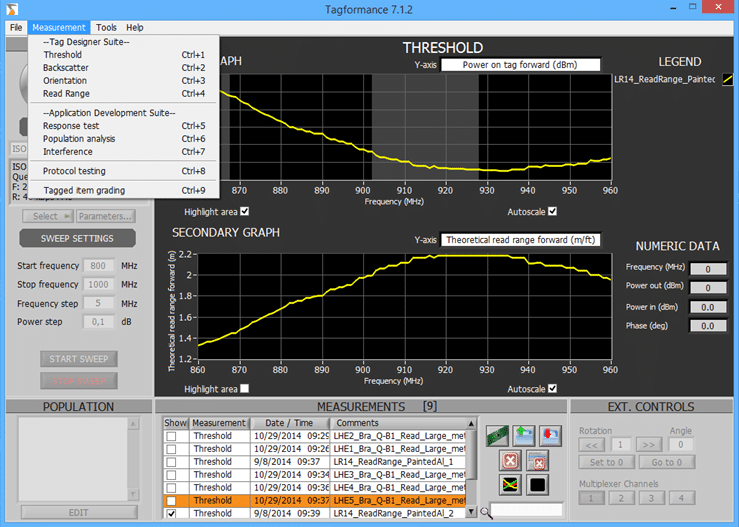

One System – Several Measurements

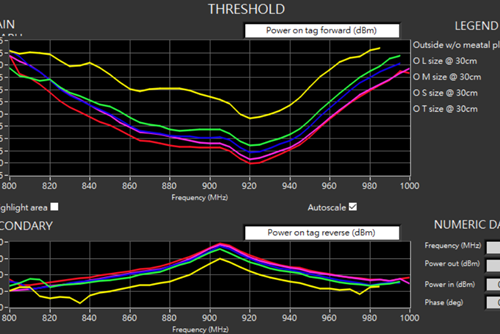

A dedicated RFID measurement system includes all the necessary measurement functions presented in a pull-down menu with suggested default settings for each measurement. Wideband sweep measurement performed over a wide frequency range of e.g., 800 – 1000 MHz enables the flexible visual presentation of the tag detuning phenomenon on different materials compared with on-air results.

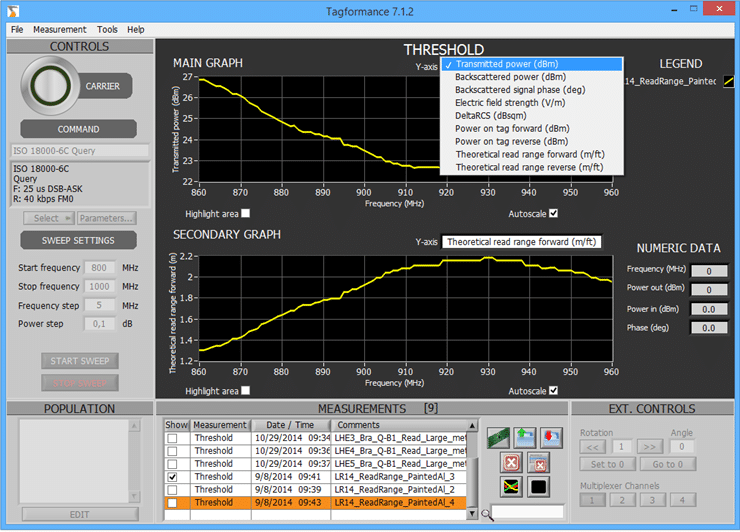

One Measurement – Several Results

One single measurement, like the Threshold Sweep, provides several calculated results (e.g., Transmitted power, Backscattered power, Electrical Field Strength, and Theoretical Read Range) that can be viewed simply by selecting the desired result view from the Y-axis pull-down menu.

Repeatability and Automation

Once the user has selected the function and started the measurement with relevant parameters, the test system provides the results that are stored in the results database with a timestamp and detailed information on all the parameters used in the measurement. Error-prone human interaction and handling of the results are avoided by automated calculation and management of the results.

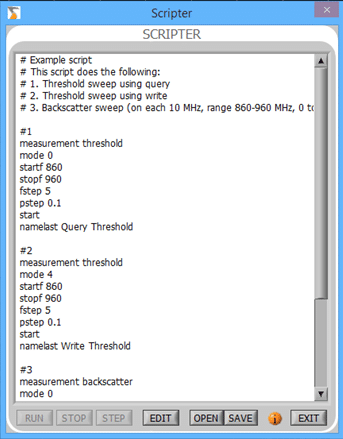

The quality of the measurements can be further ensured by defining and storing a sequence of measurement commands (Scripter) for repeated use. Predefined script together with automatic rotation system eliminates human errors when performing e.g., orientation sensitivity measurements in various positions between 0 and 360 degrees. The example script below defines a sequence of two Threshold measurements and one Backscatter measurement.

Conclusions

A purpose-built RFID measurement system combines high measurement accuracy, versatile measurement capability, and ease-of-use – a unique combination that cannot be achieved with traditional methods.

Accordingly, the improvement of the R&D team efficiency is based on:

- Quick set-up of the system

- Better visibility to the performance of the tag under test

- More measurements in the time available

- More tests on alternative tag designs in a shorter time

- Avoiding human errors

- Testing made it possible for non-RF specialist

- Shorter time to market for new tag designs.

If you want to learn in detail how the Voyantic Tagformance UHF Measurement System can improve the efficiency of your organization, please download the Tagformance Catalogue below!

Download the Tagformance Pro Catalogue

Learn more about the Voyantic Tagformance® Pro Test Device! By combining RAIN RFID and NFC testing into one compact test device, our all-new Tagformance Pro is a true all-in-one tool for anyone either developing or using RFID technology.