I talked with Voyantic’s Solution Specialists, Lasse Saarinen and Gerald Smid, about their work in the field with production testing clients.

Voyantic provides quality testing systems for various label and tag production machines, for different stages in the production process. Although Tagsurance 3, our next-generation production testing system, is easy to integrate practically into any machine, there are always variables and machine features where our customer service team is needed to support the implementation and commissioning of the system. They are also at the forefront of demonstrating our system performance to prospective customers.

But what is it like to work in the field with Voyantic’s prospects and customers? To find out, I decided to talk with Voyantic’s Solution Specialists, Lasse Saarinen and Gerald Smid.

The role of Voyantic’s Solution Specialists is to support customers in finding the best solution for customers’ needs, integrating Voyantic systems, conducting product demonstrations, and providing training as needed. They are closely involved with both current and prospective customers. The job also involves a fair amount of travel to customer sites and various events.

– Voyantic is not just a “systems provider” but our customers receive assistance and support for system implementation, benefiting from our expertise and excellent customer service, explains Lasse.

– So, we provide solutions to our customers, summarizes Gerald.

And what does your work involve in practice?

– Typically, when a system is sold to a new customer we visit the customer on-site and ensure that the installations are working correctly. – On the second day, the customer does it themselves, and we are immediately available when questions arise.

– When the customer does it themselves, they learn the best. Soon, the customer’s questions become more detailed.

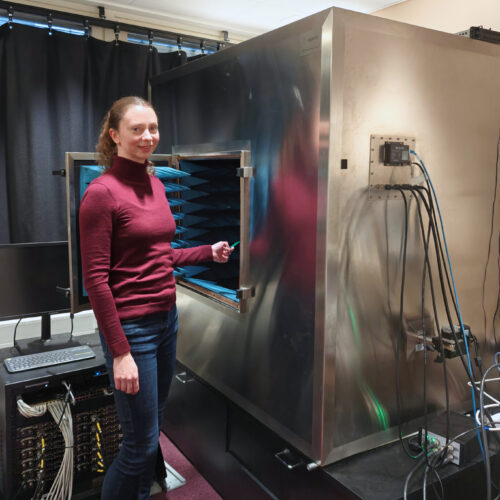

– After meeting face-to-face, it’s much easier to communicate both ways. We often have remote meetings in the demo room when demonstrating systems via camera. Video connection helps to some extent, but of course, it doesn’t replace being at the customer’s site for 2–3 days.

Who are the typical production testing customers and what challenges does Voyantic help to address?

Typical customers for Voyantic’s production testing solution are either machine manufacturers who make production machines for different stages in the RFID label production process or companies that use the machines to make RFID inlays and finished labels. I asked Gerald and Lasse what are the machine types they see in the field.

-Machine manufacturers’ machine types include chip attachment machines, label converting machines, RFID inlay insertion machines, and different kinds of finishing and control machines where our RF quality testing system can be integrated, Lasse explains.

-Customers can also be broadly divided into those for whom RFID production is new and those who already produce RFID labels, Gerald defines. -One typical customer group, for example, includes label manufacturers. They receive requests from their customers to include RFID tags in labels and then try to figure out the best way to do it. This customer group naturally has many questions related to RFID technology in general.

– Another typical customer group is those already producing RFID labels with an existing, perhaps reader-based testing method. They might want to upgrade their system to a more comprehensive system.

– Many questions revolve around the installation of the testing system: How to integrate the system, and how quickly can the line run?

– A customer may have their own testing system. They can test to some extent whether the tags work but may not know if they meet the required quality standards.

– And if it’s a legacy testing system, the person who created the system may have retired, and no one else knows how to develop it. And there may not be spare parts available for the old system anymore.

Why is testing RFID labels so important?

It was mentioned that some customers may even have self-made testing systems. Why, for example, is a reader-based testing system not sufficient for an RFID label producer?

– Well, everyone knows the radio. We’re talking about frequencies. I could compare it to reader-based systems figuring out if the radio works. If something is heard, the radio works. In our system, using this analogy, in addition to hearing the radio, you identify different radio stations that are heard.

What are some tangible benefits of Voyantic’s testing system?

– Consistency, both Lasse and Gerald agree.

– Rejecting tags that don’t meet the predefined performance requirements.

– When the production output is consistent the read distance stays roughly the same in the end-use case. If there are deviations, it works less well.

– Several meters of read distance may be lost with tags that are not consistent. If the tag is designed to be read from 3 meters away and doesn’t work, the system doesn’t recognize the product at all. That is why consistency is a vital element in RFID tag production.

– One reason for testing RFID tags is simply the quality requirements that many customers know to demand from the tags.

– Quality test requirements also come from quality certifications. RFID tag production can be quality-certified, and there are test criteria that tags must meet to receive a certain certification. Then the tags must be tested in a specific way. The quality of the manufactured product must match the criteria.

What kind of classification are we talking about?

– The University of Auburn has the ARC program. Auburn’s ARC program has become a main quality certification for the RFID industry. It is the source of the criteria for testing.

– The need to prove quality is a basic requirement of any quality system, such as ISO 9001-based systems. These standards do not have detailed criteria for the testing, but some way to show the quality of the product is needed. We help tag manufacturers to use the quality control systems in a good way.

-The starting point is that if you want RFID on labels, it’s advisable to test them. Only through testing can any issues with the performance of the RFID label be identified before they go to customers.

– One feedback we have received from our customers after acquiring the systems is that when even one bad production lot is not delivered to the customer, the system has already paid for the investment, Gerald says.

– For future customers, we could encourage them by advising them to go ahead boldly. Our systems are surprisingly easy to use once you understand the concept, and you can always get help, the Voyantic Solution Specialists summarize.

All blog posts