RFID reader frequencies are controlled by governments and limited to narrow frequency bands that vary around the world. When the performance of a UHF tag is evaluated, focusing only on the narrow reader frequency bands is misleading. I have seen in several RFID projects, how the tag performance in field conditions is different from what is expected, leading to delayed projects and expensive re-planning. Testing in a wide frequency band is needed to get the correct information about and good visibility into UHF RFID tag performance.

Detuning as a Challenge

Typical UHF RFID tags operate with a wide frequency band. However, performance still depends on frequency. In UHF RFID tag development, the tags are usually designed to have maximal read range at the reader frequency. This is achieved by tuning the tag to be most efficient at these frequencies.

Detuning creates challenges:

When the tags are attached to different materials, their performance at the reader frequency changes.

The entire performance curve shifts on the frequency scale and a change in read range is observed at the UHF RFID reader frequency. This detuning effect is one of the fundamental physical phenomena affecting real-life RFID system performance. If the detuning is not taken into account, the UHF RFID tag’s read range may be only a fraction of what is intended.

In good design, the detuning is anticipated and taken into account. If the tag is intended to be used on a material that causes 50 MHz of detuning, it can be tuned to have optimal free air performance at a frequency 50 MHz higher than the reader frequency. When the tag is on the material, the tuning and performance become optimal.

If the tag is only tested at the reader frequency, it is almost impossible to design the tuning correctly. A wideband view is needed.

Comparing Tag Designs

An example: An RFID user manufactures items made of rubber. The items are delivered on a cardboard package. The user wants to tag the cardboard boxes and wants to have a maximal read range. The items are shipped, and the RFID tags are read globally. What kind of tag would be the best?

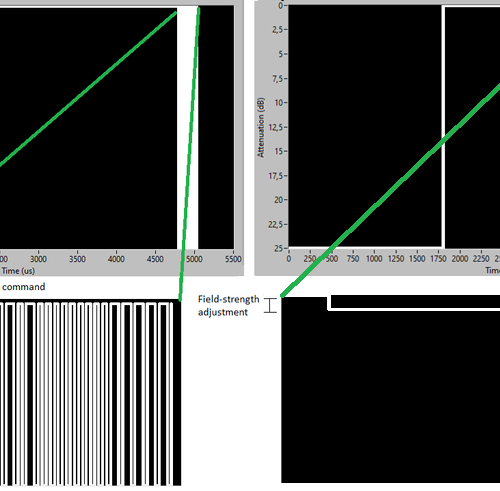

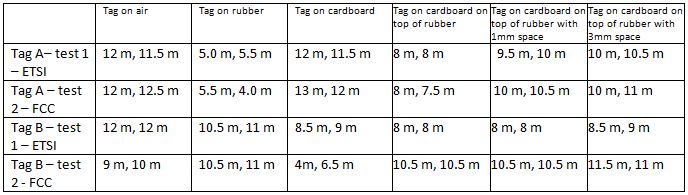

Two tag designs were tested using UHF RFID readers with ETSI (865 MHz -868 MHz) and FCC (902 MHz – 928 MHz) frequency bands. In the test, the reader was moved closer to the tag, and the distance was measured when the tag was read the first time. Each test was made twice.

The results show a big difference in read ranges. Tag design A has a 12 m read range on cardboard, but only 5.5 m on rubber. Tag design B has an opposite performance change: 11 meters on rubber and 6.5 to 8.5 meters on cardboard. There is also a difference between repeated measurements, which is significant, especially on the FCC frequencies.

What Really Happens with the UHF RFID Tags?

Because the reader frequency is limited, it is difficult to get a good overview of what is happening when the tag is attached to different materials. The read range is different in various test scenarios, but it is not clear why. Some explaining phenomena immediately pop into the minds of RFID professionals: multipath propagation and detuning. But the results from reader frequencies do not tell how the detuning works.

Which tag would you recommend? Click below to view the wideband test results of the Tags A and B from the Tagformance system or send me an email and let’s talk more! Voyantic offers RFID measurement systems to help tag designers. With precise test results, it is easier to give recommendations with confidence!

All blog posts