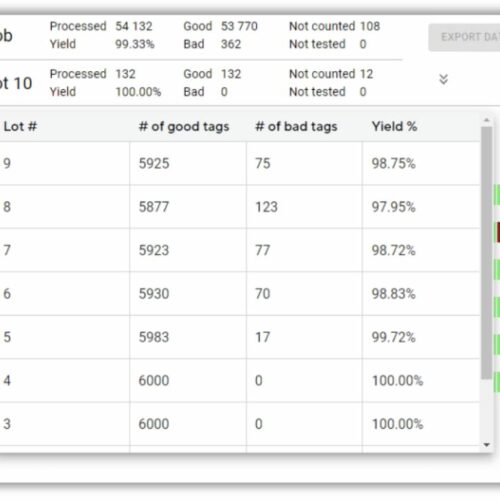

In a recently published success story, Mr. Kevin Kuo, Technical Manager of a Taiwanese RAIN RFID and NFC tag manufacturer SAG discussed the improvements they have seen in production after taking the Voyantic Tagsurance HF system into use. He mentioned the improved capability to detect tags that are not working as specified, and also 200% increased production capacity. In this article, I explain more in detail some background features enabling the improvements.

“Tagsurance HF testing speed is much faster than normal commercial HF reader. The UPH has been increased over 200% after Tagsurance HF replaced the commercial reader in our converting line. Tagsurance HF can sort out those weak performance tags that a normal reader is unable to achieve. More importantly, Tagsurance can also record each tag minimum turn-on power, which is very useful information for our engineers to adjust the machine manufacturing parameters and to enhance the tag quality control.”, said Mr. Kevin Kuo, SAG Technical Manager. Let’s look at the two main improvements in detail.

200% increase in NFC label tag production capacity after installing Tagsurance HF

This amazing capacity increase was achieved entirely without adding new machinery. The capacity increase has its’ roots in the Tagsurance system. Tagsurance is an integrated real-time system, whereas typical NFC readers are combinations of a reader, computer, and reader software, or at least combinations of integrated reader + computer and software. These divided systems spend some time in moving data between the system parts. With Tagsurance, there is no time wasted on any overhead activities, and the data handling is optimized.

NFC communication standards are powerful and enable a large number of different use cases. The downside is that in typical use cases, the communication time is not minimized. There is a lot of communication flowing between the tag and reader, even in a simple read. The Tagsurance system is purpose-built for high-speed production quality testing. Some of the typical reader functionalities are left out, and focus is on a higher speed.

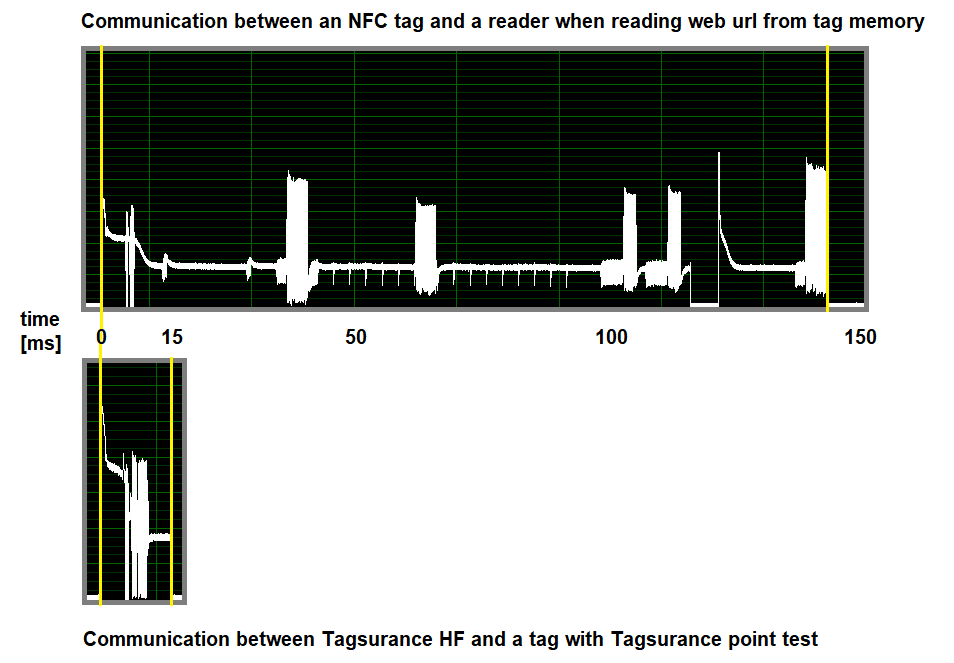

The difference is clearly visible when communication of Tagsurance HF and an NFC tag is compared to communication between an NFC reader (smartphone) and a tag. In the below picture, the communication is recorded with Voyantic Protocol Analyzer hardware and downconverter. The time Voyantic Tagsurance needs for checking the tag quality is a fraction of the time a typical reader needs when reading the NFC tag.

Replacing NFC reader with Tagsurace increases production capacity because Tagsurance HF:

- is an optimized real-time device

- does not need overhead time for moving data between system parts

- is purpose-built for high-speed quality testing

- uses NFC protocols efficiently for quality testing

-> 200% production capacity increase

Sort Out Tags With Weak Performance

Being a quality test device, the Tagsurance HF is capable of accurately sorting out good tags from non-performing ones. It is more interesting to look at why a regular NFC reader cannot do the sorting as well.

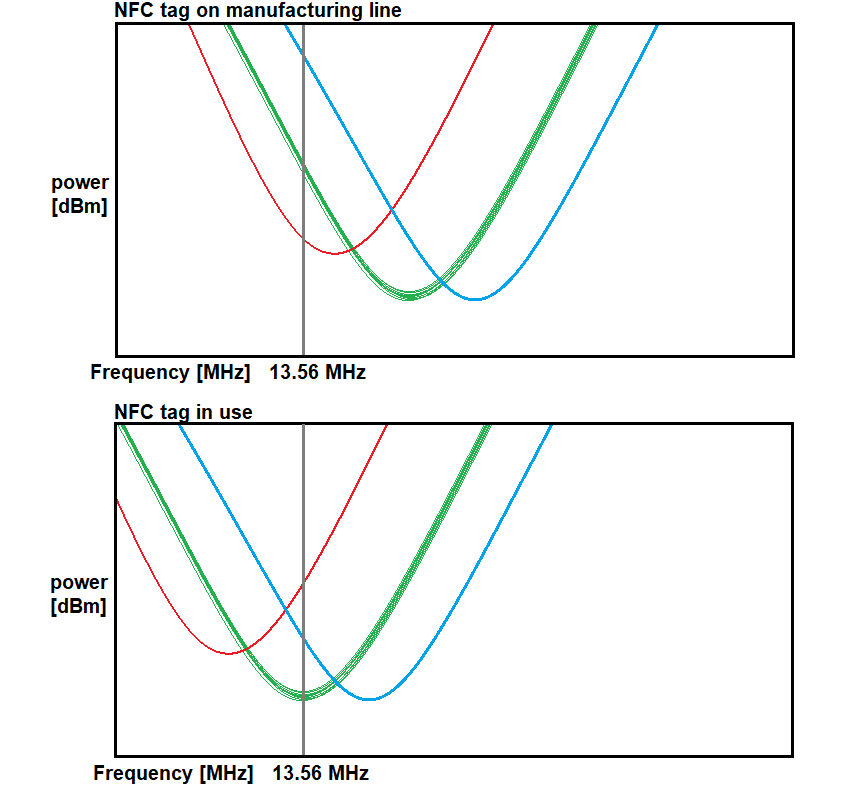

It starts with NFC tag performance. NFC tags are designed for different uses and are thus tuned differently, that is: the frequency where the tag needs the least amount of power is different. This frequency shifts to the 13.56 MHz HF RFID frequency only when the tag is in its typical use.

In the production line, the tag is not in its typical use environment, but the reader is still limited to operate on the 13.56 MHz. As a result, the reader only shows if the tag operates with 13.56 MHz in the manufacturing line. And how the tag works with a reader on the manufacturing line may be completely different from – let’s say someone is having the label glued behind a glass window or carrying a travel ticket inside a wallet.

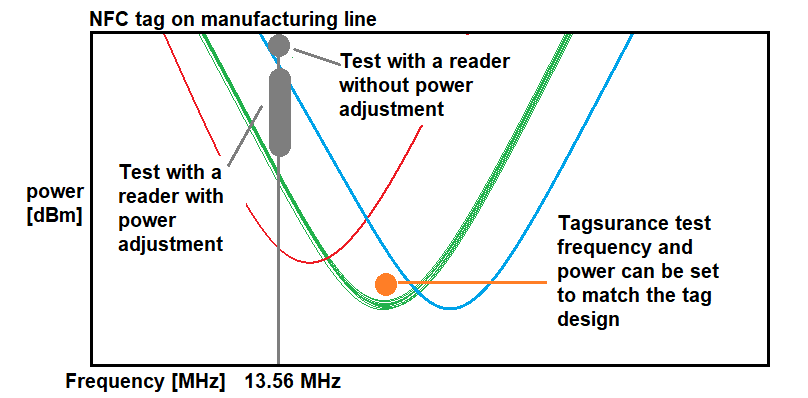

In the below example, the tag with red tuning is out of specs, but in a production environment, it may even appear better than the good tags, even though in use, it requires a lot more power (does not work as well).

Tagsurance HF is not limited to the reader frequency. It uses the frequency that is relevant for determining the quality of each tag design.

Another limitation of a typical NFC reader is that they are not accurate and calibrated test devices. Many readers just have their own (high) power level designed to maximize tag reading probability; some readers may have a power setting but not calibrated. As a result, the readers cannot properly detect tags that are working out of specs.

Having exact performance information also enables production personnel to adjust the machine parameters based on real data, and to enhance the tag quality. Our expert team has seen many cases of the tremendous impact of the Tagsurance system in various production lines with ‘side effects’ being improved transparency to Quality Assurance and better communications with suppliers and customers. Tagsurance is truly a unique asset that can drive impressive results in the production environment.

Download the Tagsurance Catalogue

Learn in detail how the Voyantic Tagsurance UHF and HF testers can improve the efficiency of your organization!