Electronic Vehicle Identification (EVI) is a perfect match for RAIN RFID (UHF RFID) technology. Once a vehicle is tagged, the possibility to identify the vehicle remotely enables a lot of applications and services. While vehicle tagging is of high interest, it is not the easiest task. In the past few months I have worked with some vehicle tagging projects and learned that the application requires some special attention from technology providers.

EVI Tag Types

The EVI tags come in different forms. Most common EVI tag types are

- windshield tags attached to the windshield inside the car; and

- license plate tags mounted on license plates outside the vehicle.

There are some specific design issues related to both of these tag types.

License plate tags must be on-metal tags, and very durable. They must survive weather conditions and car washing. Also, the position and the mounting angle are rarely ideal for readers. The natural best reading direction is straight backward (or forward), and at low height. In many applications the goal is to identify a vehicle approaching an identification point, for example an access gate or a road toll collection point. Reading would preferably be done from above or from side with an angle.

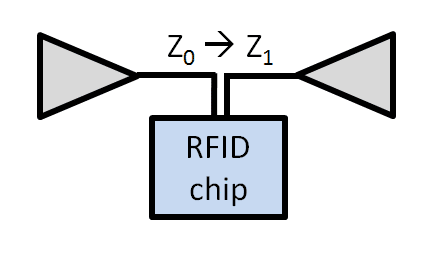

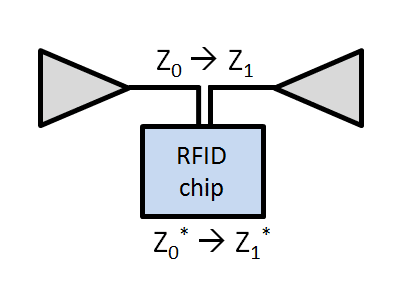

Windshield tags provide better reading angle. The challenge is to design a tag that works well with all possible windshields, regardless of the windshield’s angle, thickness, material, embedded technologies and type and proximity of the windshield frame to the tag position.

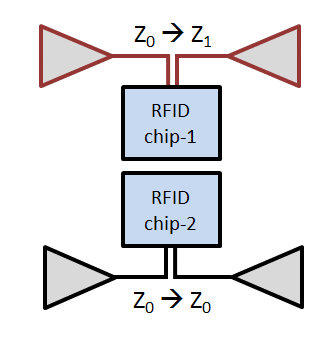

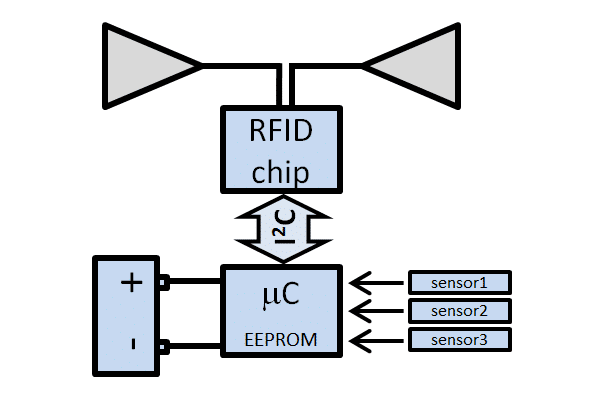

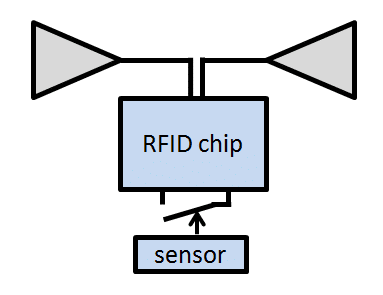

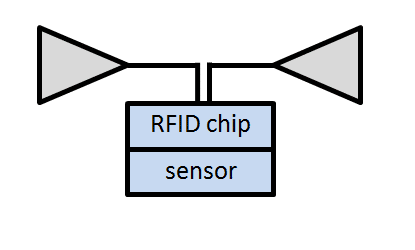

Both passive and semi-passive tags are commonly used. The semi-passive tags are battery powered; more of those can be read in earlier Voyantic Blog post.

EVI Tag Applications

Once the tagging is successful, it is easy to find use for the tags. Applications include road toll collection, tracking vehicle registrations and inspections, tracking tax payments, and parking control. Many of the applications are initially set for government purposes. Once the tags are in place, they can also be used in various value added applications of the private sector. Even if the tag is initially placed for registration, it can be used as a parking permit and gate access permit of a housing community.

Performance Testing of EVI Tags

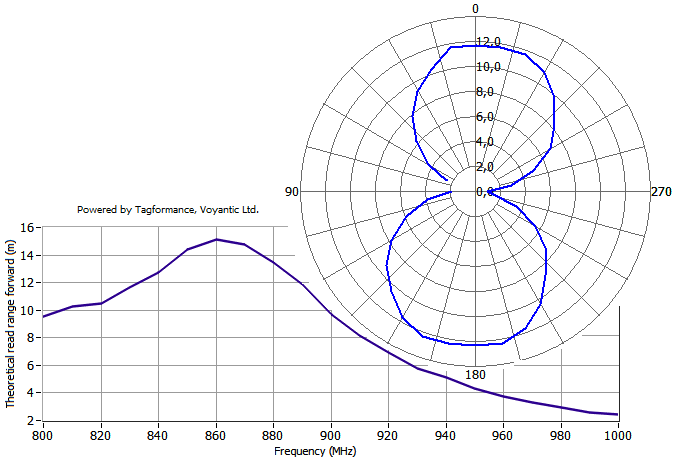

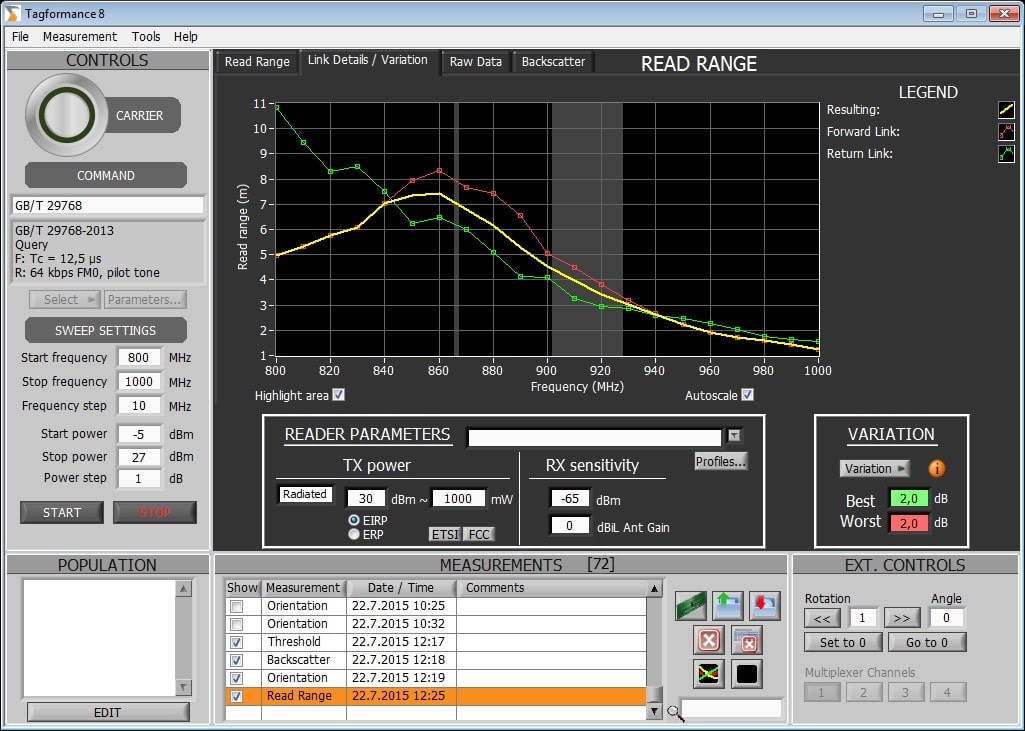

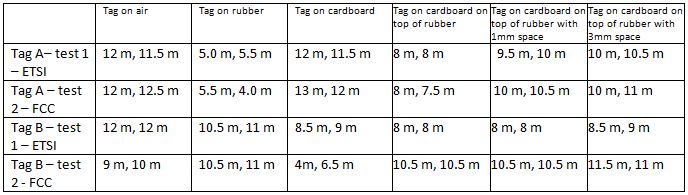

A car is a special case of a tagged item. There are components that reflect RFID signals, absorb or block the signals, and may even resonate with RFID frequencies. These effects are different to different reading angles, they vary when a tag is attached to different position in a vehicle, and may even change when a tag’s mounting orientation changes. At Voyantic we have assisted several companies in defining test methods and processes for optimizing the EVI tag performance.

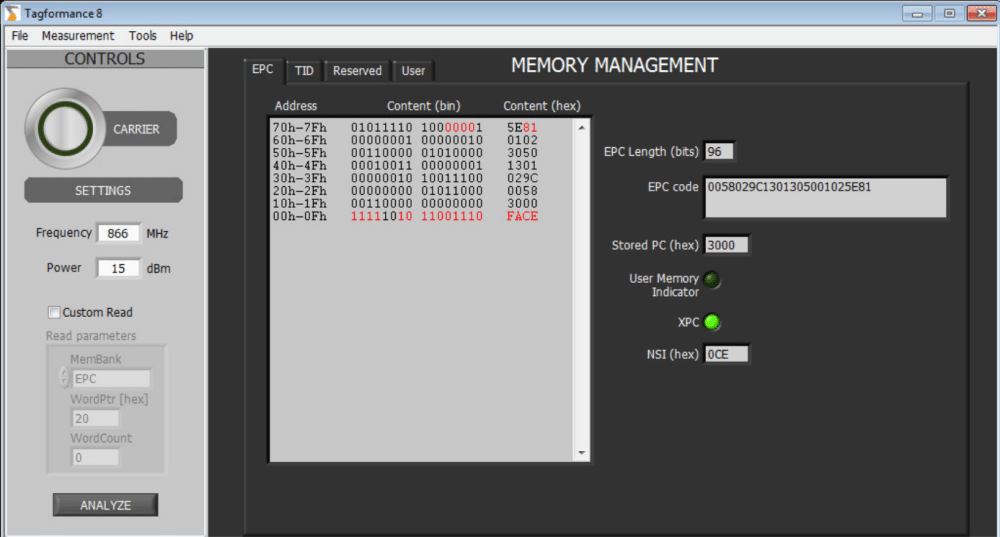

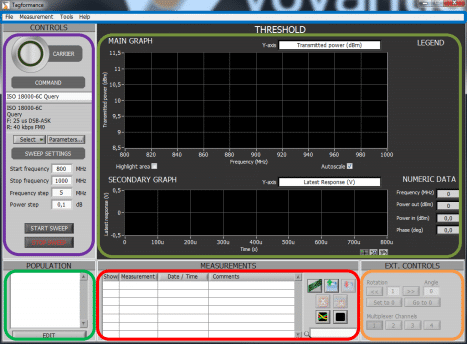

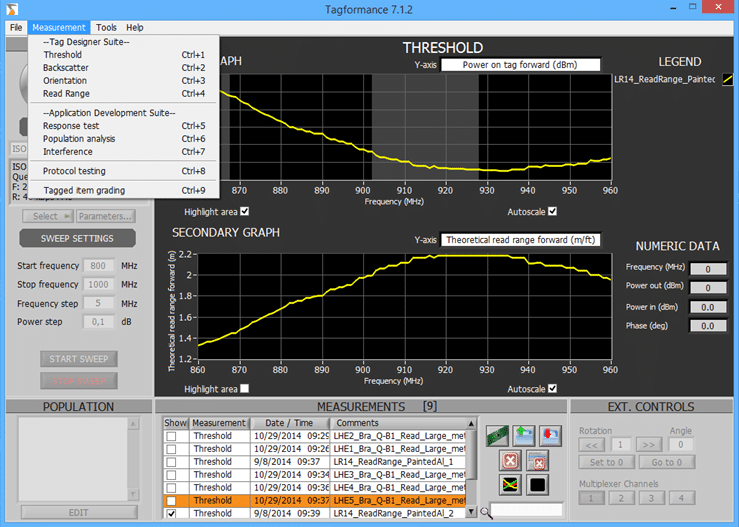

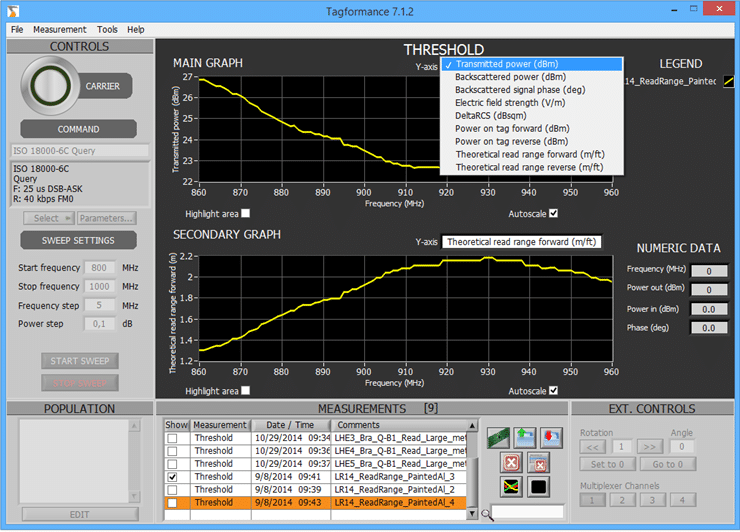

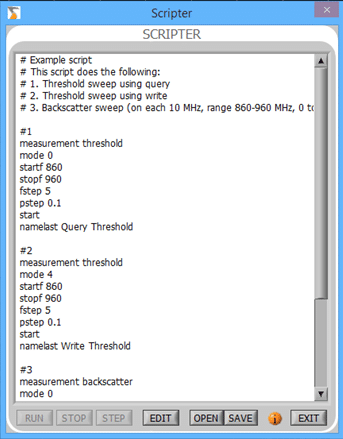

With the Voyantic Tagformance Pro system it is possible to test the sensitivity, tuning and backscatter signal strength of the car tag. The Tagformance system is an essential tool for evaluating effects of reading angles and mounting positions. The system can also be used for optimizing the EVI tag performance, finding optimal tag positions in the cars, and for finding optimal reader antenna positions for the applications.

Learn How to Test EVI Tags with Tagformance Pro

Download our application note to learn how to avoid the pitfalls of EVI tag testing!