I have visited NRF a half-dozen times, and know the challenge is the size of the exhibition: 1,000+ exhibitors, 35,000+ visitors spread over two gigantic halls at the Javits Center in New York. It’s easy to get overwhelmed and lost in there.

The three days spent at the show gave a fresh perspective into the forces that shape the future of retail. The angle I was specifically interested to learn more about is how the RAIN RFID market is evolving.

Lost and Found Buzzwords

Artificial Intelligence, AI, was The Buzzword, hands down. I saw less augmented reality on display than on the previous year and, surprisingly to me, sustainability was well hidden, practically non-existent. It serves to mention, that Digital Product Passport (DPP) was only highlighted on a couple of booths.

Grand Theme #1 – Loss Prevention

For the suppliers in the retail space, chargebacks are the elephant in the room that only a few have talked about in public, except for at the RVCF or GS1 events. For retailers as I gather, a similar pain point is loss prevention. Solutions and practices to address this area are very much rooted in the latest breed of inventory technologies, which lead to the ability to trace items and events, and ultimately in the data analysis that follows. I was specifically impressed with Sensormatic’s Shrink Analyzer.

The obvious 1st goal for everyone is to prevent loss in the first place, but without putting employees or store associates at risk. The second goal is to detect theft so that the inventory can be replenished without unnecessary delay. The third goal is to address the root cause of the issue. As heard from Joe Coll, Vice President Asset Protection Operations & Strategy at Macy’s, thanks to the advanced blend of inventory control, video surveillance, and other methods, retailers today are capable of serving air-tight cases of theft to law enforcement to study and prosecute.

All this is rooted in the ability to track inventory and events across stores and supply chains. In essence that requires item-level traceability, for which RAIN RFID is the dominant solution.

Grand Theme #2 – Consumer Experiences

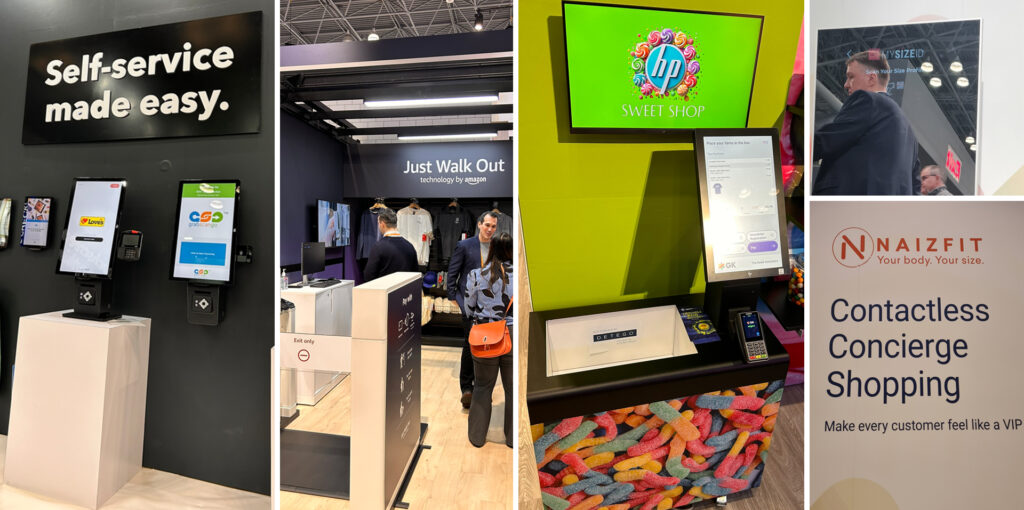

The grand theme that many companies promoted was the increasing convenience of the consumer shopping experience. It builds on several factors: omni-channel sales, the right product selection on the shelves, associates that can focus on the customer, and fast self-checkout processes. Engagement and VIP-like experiences can be necessary add-ons, depending on the retailer’s market positioning.

Oddly, in a high-volume grocery business, product identification in checkout is still much reliant on barcodes. In lower-volume but higher product-value retail, product identification is more often based on RAIN RFID. As an example, the Amazon Just Walk Out concept has already been deployed at several stadium sports merchandise stores.

Interpretation of Themes

Putting past trends, such as omnichannel, BOPIS, and labor shortage, together with the new buzzwords, such as AI, loss prevention, and self-checkouts, leads me to think that traditional brick-and-mortar stores are becoming convenient fulfillment centers, where all events are being monitored and studied.

In a panel discussion with Levi’s, PacSun, and Nedap, Levi’s VP of Global Direct to Consumer, Kirsten L’Orange, noted her personal view, that RAIN RFID is enabling data mining in the stores! According to L’Orange, ”Omni-channel execution without RFID is not possible. […] The cost of RFID has come down tremendously.” Shirley Gao, CDIO at PacSun shared the benefits RFID has provided for PacSun: 30% from revenue uplift, 30% from savings in shipping costs, and 30% from shrink reduction.

I feel it’s cool to be able to state that stores are morphing into fulfillment laboratories.

It’s hard to imagine a laboratory without data. Going forward it may also become difficult to conceptualize a retailer without accurate inventory – almost the same as a consumer without a smartphone. As of today, I don’t see any other technology being able to provide similar transparency into supply chains and inventories as RAIN RFID does.

What’s in the Horizon

There are a few themes that I expect to come across in future NRF events: robots doing replenishment, item life cycle traceability, DPP, and sustainability. Inventory robots seem to be available already, but on-shelf replenishment requires additional robot capabilities. I expect that lifecycle traceability, DPP solutions, and the opportunities associated are going to hit EuroCIS already in 2024, and possibly NRF in 2026-2027.

Sustainability will also be everywhere, as our future on this planet practically depends on it. More sustainable practices, transparency, and traceability requirements hit the manufacturing, supply chain, distribution, and post-POS lifecycle of the product. Often the packaging and the practical recyclability of products will need to be re-invented. With that said, I am confident there are endless business opportunities for many stakeholders within the retail space. I wonder who are the first ones to ride that early wave in the US market?

Final take for those in the RAIN RFID industry – now is the time to review roadmaps to make sure our products and service offerings are aligned with these upcoming themes and requirements!